Tips for Choosing the Right Barcode Printer for Your Warehouse

10th Dec 2025

In the world of logistics, every second counts, and the quality of labeling systems directly impacts how efficiently products move through the supply chain. Barcode printers have become the backbone of warehouse management, ensuring smooth inventory tracking, order fulfillment, and real-time visibility across operations. Choosing the right printer requires more than a quick purchase—it means understanding how print technology, label materials, and long-term usability align with specific warehouse needs. Investing wisely in thermal barcode printers helps enhance speed, reliability, and accuracy while reducing costly downtime.

Understanding the Printing Technologies: Direct Thermal vs. Thermal Transfer

Before purchasing a printer, understanding the two main printing methods—direct thermal and thermal transfer—is essential. Direct thermal printers use heat-sensitive labels that darken when exposed to heat. These are ideal for short-term use, such as shipping or temporary inventory tags. Labels like premium top-coated direct thermal labels offer higher durability and resistance to fading, making them reliable for daily warehouse tasks.

In contrast, thermal transfer printers use a ribbon that melts ink onto the label, creating durable prints suited for long-term labeling. Options like custom thermal transfer labels work well for environments requiring exposure resistance, such as outdoor storage or chemical packaging.

Evaluating Print Volume and Speed Requirements

Every warehouse has distinct printing demands. Some facilities require constant label printing, while others only print in batches. For continuous workflows, high-quality thermal label printers are an excellent investment. These machines maintain consistent performance, even under heavy use, while ensuring clear and smudge-free printing.

For operations that require flexibility or mobile labeling, compact options like portable label makers are ideal. Their lightweight design allows workers to print labels directly where products are picked, packed, or shipped. Matching the printer’s speed and capacity to the warehouse’s workload prevents bottlenecks, improves workflow, and ensures reliable labeling even during high-volume periods.

Material Compatibility and Label Flexibility

Warehouses often handle various products requiring different label types, adhesives, and finishes. A printer that supports multiple label materials ensures greater adaptability. For example, facilities handling colourful or detailed inventory systems benefit from affordable blank inkjet labels, which allow high-quality printing and vivid graphics.

For high-output environments, options like laser sheet labels can help streamline large batch printing. Having label flexibility also supports future expansion—whether switching to moisture-resistant labels or integrating colour-coded systems for improved organization.

Connectivity and Software Integration

Modern barcode printers are not just standalone devices—they are part of a connected ecosystem. Integration with warehouse management systems enables real-time tracking and automated printing processes. Selecting a printer that supports multiple connections, such as Wi-Fi, Bluetooth, and Ethernet, helps link it seamlessly across departments.

Using the best label design software for printers ensures that labels remain uniform and compliant with warehouse standards. Custom templates, auto-generated barcodes, and cloud-based syncing make it easier to manage high-volume printing while maintaining data accuracy. Reliable software integration reduces manual errors and enables faster labeling with minimal operator intervention, making it a key factor when choosing warehouse printers.

Maintenance and Supply Management

A barcode printer’s reliability also depends on the quality and consistency of its maintenance supplies. Ensuring steady access to ink, ribbons, and cleaning materials prevents workflow interruptions. Warehouses can buy ink cartridges for printers or compatible ribbons from trusted suppliers to keep machines running at optimal performance.

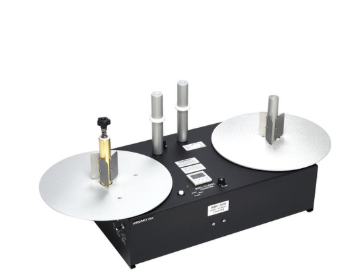

Keeping track of label usage through a label counter machine helps monitor printing activity and reduces waste. Regular cleaning, scheduled calibration, and the use of genuine consumables protect the print head from wear, extending the machine’s lifespan. A well-maintained printer is not only cost-efficient but also vital for consistent labeling quality and operational continuity.

Assessing Versatility and Future Readiness

As warehouse demands evolve, having equipment that supports expansion is critical. Scalable printers that adapt to different label sizes, print speeds, and connection types are an excellent long-term investment. Many warehouses are also shifting toward more advanced systems that combine barcode and receipt printing, enhancing versatility across applications.

Exploring POS receipt printers options allows operations to integrate receipt and label printing in one unified workflow. Printers designed for scalability ensure that as a warehouse grows, labeling systems can easily adapt without costly replacements.

Exploring Print Resolution and Image Quality

For warehouses handling diverse product ranges, print clarity has a direct effect on scan precision and inventory accuracy. High print resolution ensures each barcode or image remains sharp and easy to read, even under tough lighting or handling conditions. This is particularly useful for small components or intricate product tracking. Adjustable resolution features let teams switch between compact asset labels and large shipping tags effortlessly.

Printers that support materials such as laser sheet labels deliver crisp images and consistent tones, helping businesses maintain professional-grade labeling standards. Clear, readable labels also reduce scanner errors, saving time and preventing misplacement in busy storage areas.

Prioritizing User-Friendly Operation and Setup

Ease of operation is another important factor when choosing a warehouse barcode printer. Intuitive touchscreens, automatic calibration, and guided ribbon installation simplify daily usage and minimize errors. A user-friendly printer reduces the need for specialized training, enabling quick onboarding for new staff members.

Models designed for smooth system integration often feature multi-language interfaces, making them accessible to diverse teams. Devices compatible with POS receipt printers add versatility to warehouse environments where transaction or shipment confirmations are part of labeling duties.

Selecting Compatible Scanners and Accessories

While printers create labels, scanners complete the data cycle by capturing information accurately. Pairing printers with compatible scanning tools ensures instant data synchronization and accurate inventory tracking. Businesses can buy barcode scanners online to complement their printing systems, ensuring smooth transitions from label creation to product tracking.

Compatibility across printers, scanners, and software builds an efficient ecosystem that minimizes manual errors and improves real-time visibility. Investing in reliable accessories today sets the stage for operational excellence tomorrow. The combination of a high-quality printer, an advanced scanner, and stable software forms the foundation of efficient warehouse management.

Optimizing Label Durability for Harsh Environments

Warehouse labels often face challenges such as moisture, heat, and abrasion. Durable labeling ensures product identification remains intact from storage to delivery. Choosing materials that can withstand harsh handling conditions prevents scanning errors and product misplacement. Industrial environments benefit from advanced coating options that resist fading and smudging over time. For high-traffic or outdoor storage areas, using direct thermal labels ensures consistent readability and resistance to temperature fluctuations. Reliable labels maintain their clarity even under demanding circumstances, supporting accurate tracking throughout the supply chain. By prioritizing durability in label materials, warehouses safeguard operational integrity, minimize relabeling costs, and strengthen the accuracy of their inventory management systems. Investing in robust label types and compatible printers ensures dependable performance, regardless of the environment or workload.

Adapting to Evolving Warehouse Technologies

As warehouses transition toward automation, smart labeling systems play a critical role in maintaining data flow and efficiency. Modern printers now feature connectivity enhancements and built-in analytics, allowing seamless integration with digital inventory systems. Advanced printing technologies support faster communication between scanners, software, and robotic pickers, enhancing real-time updates. The ability to upgrade printer firmware or connect via wireless networks ensures long-term usability as systems evolve. Leveraging affordable barcode scanners together with adaptable barcode printers allows operations to function smoothly within automated workflows. This level of integration not only increases productivity but also reduces human error, creating a more intelligent and efficient labeling ecosystem. Embracing adaptable, future-ready printing technology positions warehouses to meet changing logistics demands while maintaining high accuracy and operational speed across every touch point.

Empowering Warehouse Productivity with the Right Printing Choice

Selecting the right barcode printer is not simply a technical decision—it’s a strategic investment that influences every layer of warehouse operations. From label durability to connectivity options, each choice impacts how efficiently teams can pick, pack, and ship products. A well-chosen printer enhances precision, reduces manual tasks, and ensures that every barcode represents dependable data.

The best barcode printing setup empowers logistics teams to achieve consistent accuracy and speed. By focusing on print quality, user experience, and maintenance support, warehouses can confidently build a labeling system that grows with their needs and maintains performance even under pressure. Investing in high-quality colour label printers allows operations to produce clear, durable, and professional-grade labels that strengthen warehouse efficiency and accuracy across every process.

Efficient Printing Solutions for Every Need

Warehouses thrive when supported by dependable, high-performance labeling systems designed for flexibility and endurance. At DuraFast Label Company, printing technology is crafted to meet the real-world challenges of logistics and fulfillment. Its reliable solutions are built for every printing requirement, from warehouse logistics to retail labeling. Whether seeking thermal barcode printers for operational accuracy or looking to buy thermal label printers online for everyday efficiency, the focus is always on quality and performance. Advanced printers deliver consistent results with reduced maintenance, supported by a wide range of consumables and accessories. Each solution is designed to help businesses streamline workflows, maintain compliance, and meet growing labeling demands. To discuss how our experts can assist, reach out to the team today to explore tailored options and discuss specific printing requirements.