RFID Label Printers and Their Role in Modern Supply Chain Management

18th Dec 2025

In the fast-paced world of logistics and manufacturing, visibility and accuracy are everything. Knowing where every product, pallet, or component is at any given moment is no longer a luxury — it’s a competitive necessity. As supply chains become increasingly complex and globalized, businesses are adopting RFID label printers in Canada and worldwide to revolutionize how they manage, track, and verify goods.

RFID — or Radio Frequency Identification — technology allows businesses to identify and trace products automatically, without requiring direct line-of-sight scanning like traditional barcodes. By integrating RFID-enabled labels into their workflow, manufacturers and logistics teams gain real-time insights into product movement, warehouse inventory, and even shipment conditions.

At DuraFast Label Company, we’ve seen RFID technology shift from niche adoption to mainstream necessity. Modern RFID label printers combine encoding precision, speed, and durability, allowing companies to automate data collection at every stage of their operations. Whether it’s a retailer improving stock accuracy, a logistics hub preventing lost shipments, or a manufacturer ensuring compliance tracking, RFID labeling has become a cornerstone of operational excellence.

In this complete guide, we’ll explore how RFID label printers work, why they’re essential for supply chain optimization, and how choosing the right model can drastically improve your productivity, accuracy, and profitability.

What Are RFID Label Printers?

RFID label printers are advanced printing systems that create labels embedded with RFID tags — small microchips and antennas that store and transmit data wirelessly. Unlike traditional barcodes, RFID tags don’t need to be seen to be scanned. Instead, they communicate via radio waves, allowing multiple items to be identified simultaneously, even from several meters away.

These printers do two jobs at once:

- Printing high-quality, visible information (like text, barcodes, or logos).

- Encoding digital information into the RFID chip within the label.

The encoded data might include product IDs, batch numbers, shipping details, or even environmental metrics — all of which can be read later using compatible RFID scanners or readers.

By combining visual and digital information in one step, RFID label printers bridge the gap between physical labeling and automated data capture — the backbone of Industry 4.0 manufacturing.

How RFID Labeling Works

RFID labels (or smart labels) contain two key components:

- An integrated circuit (chip) that stores information.

- An antenna that transmits and receives radio signals.

When an RFID reader emits a signal, the antenna within the label absorbs this energy, powering the chip and sending back its stored data. This wireless communication allows multiple tags to be scanned simultaneously — even when they’re behind packaging, inside boxes, or stacked on pallets.

RFID labels can be read-only (pre-encoded with static data) or read-write (which allows new data to be written or updated dynamically). This versatility is what makes RFID so powerful for supply chain operations — every product can carry a living data record throughout its lifecycle.

Modern printers, like those available through DuraFast, encode and verify each tag during the printing process, ensuring every label functions correctly before application. This eliminates the costly risk of deploying “dead tags” — RFID labels that fail to respond to scanners.

Why RFID Printing Is Superior to Traditional Barcoding

Although barcodes have been the industry standard for decades, RFID offers several clear advantages that make it ideal for large-scale, automated environments:

1. No Line-of-Sight Required

Unlike barcodes, which must be scanned individually, RFID readers can detect multiple tags within their range simultaneously. This drastically speeds up scanning during receiving, stocking, and shipping.

2. Data Storage and Flexibility

Barcodes store minimal data, while RFID chips can hold complex information — including product origin, temperature history, and expiration dates. This enables advanced tracking and traceability.

3. Real-Time Accuracy

Because RFID systems continuously communicate with readers, they offer live visibility into inventory levels and movement — reducing stock discrepancies and manual input errors.

4. Durability

RFID labels withstand dirt, moisture, and wear far better than printed barcodes, which can fade or tear. This makes them especially valuable in manufacturing, healthcare, and logistics settings where labels encounter harsh conditions.

5. Automation Compatibility

RFID integrates seamlessly with warehouse management systems (WMS), enterprise resource planning (ERP), and manufacturing execution systems (MES). The result? Fully automated workflows that eliminate human scanning errors.

In short, while barcodes work linearly, RFID enables intelligent networks of information — a digital ecosystem that moves at the speed of your business.

Components of an RFID Label Printer

An RFID label printer combines the capabilities of a traditional thermal transfer printer with advanced encoding and verification systems. Each component plays a key role in ensuring labels are printed and programmed correctly:

- Print Engine: The mechanism that transfers ink (thermal transfer or direct thermal) to the label surface.

- RFID Encoder: Writes digital data onto each tag’s chip.

- Verification Antenna: Confirms the tag’s readability before it leaves the printer.

- Control Interface: A touchscreen or software connection that allows users to configure printing and encoding parameters.

These integrated functions ensure the printer can encode thousands of labels per hour with near-zero failure rates — crucial for production-scale labeling.

A compact yet powerful option for small to mid-volume encoding is the SATO CT4-LX HF RFID Cutter Thermal Transfer Desktop Printer. It’s designed for precise label cutting and encoding, making it ideal for product-level tracking in electronics, pharmaceuticals, and packaging environments.

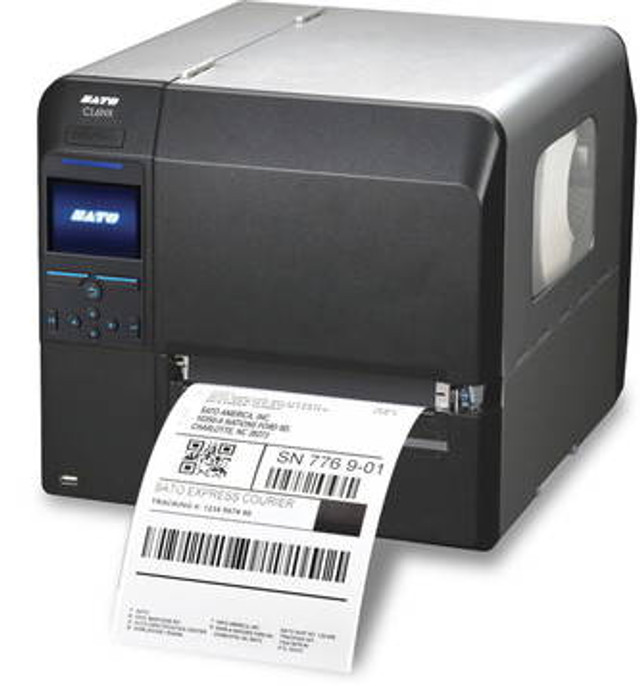

For larger, high-throughput operations, the SATO CL4NX Plus UHF RFID Thermal Transfer Industrial Printer provides industrial-grade durability and high-speed encoding, suitable for global logistics centers and manufacturing plants.

RFID vs. Barcode Label Printing: A Quick Comparison

|

Feature |

Barcode Labels |

RFID Labels |

|

Identification Range |

Requires line-of-sight |

Up to several meters |

|

Scanning Method |

One-by-one |

Multiple at once |

|

Durability |

Can fade or tear |

Resistant to wear, moisture, and heat |

|

Data Capacity |

Limited (static) |

Large (dynamic) |

|

Cost per Label |

Lower |

Higher, but offers ROI via efficiency |

|

Applications |

Retail, short-term logistics |

Manufacturing, warehousing, compliance |

While RFID printing technology involves higher upfront costs, its long-term payoff in speed, traceability, and data integrity makes it a clear winner for any organization managing complex supply chains.

A Real-World Example of RFID in Action

Consider a warehouse that handles thousands of SKUs per day. With barcode systems, staff must manually scan each label to update inventory. Using RFID, every pallet equipped with smart labels can be automatically scanned as it passes through a dock doorway. The system instantly records what was shipped, received, and stored — no manual entry required.

This reduces scanning labor by up to 80% and nearly eliminates human errors, while providing real-time visibility into every movement within the facility.

The Role of DuraFast Label Company

At DuraFast Label Company, we’ve supplied RFID labeling solutions to leading logistics, healthcare, and manufacturing firms across North America. Our expertise covers everything from printer setup and calibration to label and ribbon selection — ensuring clients achieve optimal encoding accuracy and long-term reliability.

We offer a range of RFID printers suited for every scale — from compact desktop units to heavy-duty industrial models. Each comes with expert guidance, after-sale support, and compatibility with a wide range of RFID inlays and software platforms.

Benefits of RFID Label Printers

RFID label printers aren’t just an upgrade — they represent a transformation in how information moves through your supply chain. By automating the labeling and data capture process, businesses achieve a new level of visibility, control, and precision. Let’s explore the key advantages that make RFID technology indispensable in modern operations.

Enhanced Tracking Accuracy

At the heart of RFID’s value is its accuracy. Traditional barcode systems depend on manual scanning — which is prone to human error and limited by line-of-sight visibility. RFID, on the other hand, enables non-line-of-sight data capture, meaning hundreds of items can be identified at once, even inside sealed boxes or pallets.

This means your warehouse management system (WMS) always knows exactly what’s in stock and where it’s located. Misplaced items, double scans, and stock discrepancies become virtually nonexistent. For high-volume environments where every second counts, the time savings are substantial.

RFID labels also carry unique serial identifiers, allowing individual tracking of items within a batch. This capability is critical for industries like pharmaceuticals or electronics, where product traceability and authenticity verification are mandatory.

Automation and Labor Savings

In logistics and manufacturing, speed is everything — and labor costs often represent a large portion of operational expenses. RFID technology automates many of the manual steps associated with labeling and scanning.

For example, a facility equipped with RFID label printers can automatically encode and verify tags as products are packaged. As those items move through conveyor systems, RFID readers capture their information in real time, updating central databases without human intervention.

The result?

- Up to 80% faster throughput in shipping and receiving.

- Reduced manual scanning errors.

- Lower labor costs due to automation.

When RFID-enabled printers like the Printronix T800 UHF RFID Thermal Transfer Label Printer are introduced, businesses can print, encode, and validate labels simultaneously — ensuring data accuracy and production continuity.

These printers are ideal for mid- to high-volume facilities seeking dependable RFID encoding capabilities that integrate with existing labeling systems. Combined with DuraFast’s high-quality RFID media, they deliver speed, reliability, and precision unmatched by manual methods.

Improved Supply Chain Efficiency

One of the biggest operational challenges companies face is inefficiency caused by data delays, scanning bottlenecks, and mislabeling. RFID technology solves these problems by streamlining every link in the supply chain.

Here’s how:

1. Faster Receiving and Dispatch

Instead of scanning each box individually, entire shipments can be read instantly as they pass through RFID gateways. This reduces check-in and check-out times dramatically, allowing more shipments to move per shift.

2. Real-Time Inventory Visibility

RFID systems provide live data feeds to your WMS or ERP software. This enables automatic restocking alerts, minimizes stockouts, and improves order accuracy.

3. Error Reduction

Because encoding and verification occur simultaneously, the risk of labeling errors drops to near zero. Every RFID tag is validated as it’s printed — guaranteeing that what’s encoded matches what’s on the label.

4. Data Integration

RFID printers can be networked across multiple production lines or locations, ensuring consistent label standards and synchronized information across departments.

The SATO CL4NX Plus UHF RFID RTC Thermal Transfer Industrial Printer exemplifies this power. It’s built for enterprise-scale operations requiring rugged durability, high print speeds, and precision encoding. The printer’s advanced connectivity options make it compatible with modern manufacturing software and automation systems — a perfect fit for large-scale labeling environments.

RFID in Modern Warehousing and Logistics

Warehouses are the nerve centers of supply chain efficiency — and RFID technology is redefining how they function. From inbound receiving to outbound shipping, smart labeling solutions enable real-time decision-making that reduces waste and accelerates movement.

Inventory Accuracy and Cycle Counts

RFID allows for instantaneous, contactless inventory counts. Staff can walk through aisles equipped with handheld RFID scanners or fixed readers, scanning hundreds of items in seconds without handling a single box.

Cycle counts that used to take hours or days can now be completed in minutes. This frees up teams for higher-value activities and ensures constant data accuracy across the warehouse.

Automated Replenishment and Stock Control

With RFID labels embedded into cartons or pallets, warehouse management systems can automatically detect when inventory levels fall below thresholds and trigger replenishment orders. This eliminates manual input and ensures continuous production flow.

Dock Door Scanning and Shipment Verification

RFID readers installed at dock doors capture tag data as goods move in and out of facilities. This creates an instant digital record of every transaction, improving traceability and preventing shipment errors.

In facilities that handle thousands of packages per day, automation through RFID reduces human fatigue and improves safety by minimizing repetitive tasks.

RFID Labeling in Retail and E-Commerce

In retail and e-commerce, RFID has emerged as a game-changer for inventory visibility and customer experience. Accurate labeling helps retailers maintain optimal stock levels, prevent overstocking, and enhance fulfillment speed.

Smarter Inventory Management

With RFID tags, every item in a store can be tracked individually. This enables 99% inventory accuracy, ensuring products are available when and where customers expect them.

Retailers like fashion brands and electronics stores use RFID to monitor product flow from warehouse to shelf. Real-time tracking means faster restocks, fewer lost items, and reduced shrinkage.

Omnichannel Integration

RFID enables seamless integration between online and physical stores. When an order is placed online, the system automatically identifies the nearest location with available stock, improving delivery speed and efficiency.

Enhanced Customer Experience

RFID-enabled fitting rooms and checkout systems let customers view product details, sizes, and availability instantly. This level of interactivity enhances satisfaction while streamlining store operations.

RFID in Healthcare and Pharmaceuticals

In industries where accuracy and safety are non-negotiable, RFID labeling ensures that every product is traceable, compliant, and authentic.

Medication Tracking

Hospitals and pharmacies use RFID labels to track medication batches, expiration dates, and patient prescriptions in real time. This reduces dispensing errors and ensures the right product reaches the right patient.

Asset Tracking

Medical devices and equipment labeled with RFID tags can be quickly located within hospital premises, improving efficiency and reducing equipment loss.

Regulatory Compliance

Pharmaceutical manufacturers are required by law to maintain traceability of every drug batch. RFID simplifies this process by maintaining a verifiable digital trail, ensuring compliance with FDA and global standards.

For large pharmaceutical plants, industrial-grade printers like the SATO CL6NX Plus UHF RFID RTC Thermal Transfer Industrial Printer deliver precision encoding at scale. These printers are designed to produce thousands of high-quality labels per hour with superior data accuracy — crucial for serialized pharmaceutical labeling.

Why Companies Are Upgrading to RFID Printing Systems

Many organizations that previously relied solely on barcodes are now transitioning to RFID for its scalability and intelligence. The technology’s ability to handle large volumes of data makes it ideal for digital transformation initiatives across manufacturing, logistics, and retail sectors.

Businesses choose to buy RFID printers online not just to modernize their labeling but to future-proof their operations. With global supply chains demanding transparency and automation, RFID label printers have become essential tools for staying competitive.

Furthermore, advancements in RFID printer technology — such as dual-encoding verification, IoT connectivity, and compatibility with thermal transfer ribbons — make them more accessible and adaptable than ever.

DuraFast Label Company provides enterprise clients with end-to-end consultation on selecting the best printer for their workflow, from compact desktop solutions to robust, heavy-duty models suitable for 24/7 operation.

If you’re planning to upgrade or integrate RFID into your workflow, now is the time. The long-term savings in labor, rework, and time far outweigh the initial investment — especially when choosing from DuraFast’s wide range of RFID label printers for sale.

Integrating RFID with Existing Systems

One of the biggest advantages of modern RFID printers is how seamlessly they integrate into existing workflows. For most organizations, upgrading from traditional barcode systems doesn’t require an operational overhaul — it’s simply a matter of choosing printers and software that align with your current infrastructure.

Software Compatibility and Data Integration

Most RFID label printers today are designed with enterprise integration in mind. They work with popular warehouse management systems (WMS), enterprise resource planning (ERP) tools, and manufacturing execution systems (MES). This allows you to print, encode, and manage RFID labels directly from your existing software environment.

For example:

- An ERP can generate product data and push it directly to the printer for encoding.

- The RFID printer encodes the tag and verifies it automatically.

- A WMS then reads the encoded tag during goods movement, updating inventory in real time.

This closed-loop ecosystem ensures accuracy at every stage — from manufacturing to delivery. Companies using platforms like SAP, Oracle, or Microsoft Dynamics benefit from real-time synchronization, eliminating the need for manual reconciliation.

The SATO CL6NX Plus A-Series UHF RFID Printer is designed specifically for enterprise-level integration. With advanced connectivity options (Ethernet, USB, Bluetooth, and Wi-Fi), it can connect effortlessly to local networks or cloud-based systems, providing centralized control over multi-site label printing operations.

Calibration and Encoding Accuracy

Even the most sophisticated RFID printer requires calibration to maintain optimal encoding performance. Each RFID inlay (chip and antenna combination) reacts differently based on its size, material, and frequency range. Proper calibration ensures that each label is encoded precisely without interference or read errors.

Tips for Reliable Encoding:

- Use validated RFID media — Always select labels and inlays certified for your printer model. DuraFast provides pre-tested media that guarantees compatibility and performance.

- Perform verification scans — Built-in verification antennas check each tag before it exits the printer, ensuring 100% accuracy.

- Adjust encoding power levels — Set the RFID signal strength according to the tag’s range and label thickness.

- Monitor tag performance — Randomly test printed labels using handheld RFID scanners to confirm read consistency.

RFID label printers from DuraFast, such as the Printronix T800 or SATO CL4NX Plus, include automated calibration features that adapt to media variations. This reduces setup time and ensures flawless encoding across long production runs.

Maintenance and Long-Term Performance

RFID printers, like all precision equipment, perform best with regular maintenance. Beyond cleaning printheads and replacing worn parts, RFID systems also benefit from software updates that improve encoding algorithms and compatibility with newer tag technologies.

At DuraFast Label Company, we recommend scheduling maintenance at least quarterly for high-volume users. This involves:

- Cleaning rollers and printheads with isopropyl wipes.

- Checking encoder antennas for alignment.

- Updating firmware and RFID libraries.

- Running performance diagnostics for tag verification accuracy.

Preventive maintenance not only extends printer life but ensures uninterrupted productivity — a crucial factor in 24/7 operations like logistics hubs or manufacturing plants.

Future of RFID Labeling

As global commerce accelerates and automation becomes the norm, RFID technology continues to evolve rapidly. The future promises smarter, more connected labeling systems that will redefine supply chain management.

IoT and Real-Time Analytics

The Internet of Things (IoT) is turning RFID labels into smart data transmitters. Soon, printers and labels will communicate directly with analytics dashboards, offering real-time visibility into product flow, environmental conditions, and even predictive maintenance alerts.

In this ecosystem, RFID doesn’t just track — it thinks. Labels embedded with sensors can report temperature, humidity, or shock exposure, providing manufacturers and shippers with vital quality assurance data.

AI-Powered Labeling Systems

Artificial intelligence is already being integrated into RFID-enabled labeling workflows. AI-driven printers can self-adjust encoding parameters, detect faulty tags, and optimize layouts for maximum throughput. These systems will eliminate human oversight in label production, freeing up staff for higher-value analytical work.

In logistics, AI-assisted RFID tracking allows for predictive shipping — anticipating delays, rerouting goods automatically, and maintaining complete visibility across global networks.

Sustainability and Eco-Friendly RFID Labels

As environmental consciousness grows, manufacturers are developing eco-friendly RFID labels made with recyclable substrates and non-toxic adhesives. Future RFID printers will be capable of handling these sustainable materials without compromising quality or performance.

DuraFast is actively expanding its catalog to include recyclable RFID media and linerless options — minimizing waste while supporting responsible manufacturing practices.

Blockchain and Secure Traceability

Blockchain integration is another frontier for RFID. By linking RFID data with blockchain ledgers, companies can create immutable records of a product’s entire journey — from raw materials to end-user delivery. This is particularly powerful for industries like food, pharmaceuticals, and luxury goods where authenticity and compliance are essential.

RFID printers that support serialized and encrypted encoding will become standard as global trade moves toward more transparent and secure systems.

The ROI of RFID Printing

Although the initial investment in RFID technology can seem substantial, the return on investment is significant and fast. Businesses that adopt RFID typically experience:

- 30–60% reduction in inventory management time

- Up to 99% data accuracy across logistics operations

- Major reductions in product loss, misplacement, and theft

- Faster fulfillment and reduced shipping errors

With such tangible benefits, RFID printing isn’t just a technological upgrade — it’s a financial and operational advantage.

By working with DuraFast Label Company, businesses can ensure a smooth and cost-effective transition into RFID labeling. We provide consultation on system compatibility, installation support, and a complete range of consumables tailored to your workflow.

Smart Labels for Smart Logistics

RFID labeling has evolved from a niche innovation into a global supply chain necessity. With the ability to capture, encode, and verify data automatically, RFID label printers help businesses achieve the visibility and accuracy that today’s competitive markets demand.

From real-time warehouse tracking to serialized pharmaceutical labeling, these systems remove human error, accelerate operations, and ensure total transparency from production to delivery.

At DuraFast Label Company, we’re proud to support this transformation by offering top-tier printers, supplies, and expertise that make RFID implementation effortless. Our curated lineup of printers — from compact desktop encoders to rugged industrial systems — ensures there’s a perfect fit for every business.

Explore our wide range of RFID label printers for sale, each selected for its reliability, performance, and integration readiness. Whether you’re a growing e-commerce retailer or a global manufacturer, DuraFast provides the technology and guidance to help you succeed.

Ready to modernize your operations and achieve real-time tracking across your supply chain? Contact the experts at DuraFast Label Company today to learn how our RFID label printers in Canada can revolutionize your labeling strategy from the ground up.

Contact DuraFast Label Company — your partner for smarter, faster, and future-ready labeling solutions.