How to Use Vinyl Labels for Industrial and Commercial Applications

5th Dec 2025

In industrial and commercial environments, labels don’t just display information — they must endure. From harsh outdoor weather to chemical exposure and constant handling, industrial labeling demands a level of toughness that ordinary materials can’t provide. That’s where vinyl labels come in.

At DuraFast Label Company, we’ve worked with countless manufacturers, logistics companies, and construction firms that require labels that remain legible, adhesive, and intact through everything from heat and moisture to abrasion. Vinyl’s strength, flexibility, and resilience make it the gold standard for demanding workplaces.

Whether used for equipment marking, safety signage, cable identification, or outdoor branding, vinyl labels perform where paper and polypropylene fail. In this guide, we’ll explore their advantages, practical applications, and how to select the right vinyl label for your business.

Why Vinyl Labels Outperform Other Materials

Vinyl is a synthetic plastic material made from polyvinyl chloride (PVC), engineered for exceptional durability. Its key advantage lies in its resistance to tearing, stretching, and environmental damage. Unlike paper-based labels that degrade under stress, vinyl maintains its integrity in extreme conditions.

Unmatched Durability

Vinyl labels withstand exposure to oil, moisture, and chemicals without losing print quality or adhesion. This makes them ideal for automotive, marine, and construction applications where exposure to solvents or rough handling is common.

Weather Resistance

Vinyl labels are UV-resistant, waterproof, and flexible even at temperature extremes. They perform just as well in a cold warehouse as they do on hot outdoor machinery, remaining legible for years.

Long-Term Adhesion

Thanks to advanced adhesive formulations, vinyl labels adhere to rough, curved, or uneven surfaces where other materials peel away. The flexibility of vinyl allows it to conform tightly without wrinkling or bubbling.

Professional Print Finish

Vinyl accepts a variety of printing technologies — including thermal transfer, inkjet, and laser — delivering sharp, professional results. When combined with resin ribbons or pigment-based inks, prints remain fade-proof for years.

Industrial Applications of Vinyl Labels

Equipment and Asset Identification

Factories, plants, and warehouses rely on equipment labels to track machinery, maintenance schedules, and safety warnings. Vinyl labels’ rugged surface ensures barcodes and serial numbers remain scannable over time, even in dusty or greasy conditions.

For example, the Dymo 18445 Rhino ¾” White Vinyl Tape is designed specifically for tough labeling on curved or textured surfaces, making it ideal for cables, panels, and industrial equipment.

Outdoor and Construction Environments

Vinyl’s UV resistance makes it a top choice for outdoor labels used on tools, vehicles, and site signage. Unlike paper or film labels, vinyl doesn’t yellow or crack under sunlight, rain, or temperature swings.

The MAX Letatwin LM-TU432L2 Vinyl Tube Roll demonstrates this perfectly — it provides clear, durable tube labeling for electrical wiring and industrial piping, essential for safety and maintenance.

Chemical and Laboratory Environments

In chemical plants and labs, exposure to solvents, alcohols, and cleaning agents can quickly destroy standard labels. Vinyl’s resistance to such substances makes it the only reliable choice for containers, bottles, and testing equipment.

Marine and Automotive Use

Salt, moisture, and temperature variations make marine and automotive labeling especially challenging. Vinyl labels used in these sectors must cling firmly to metal and plastic surfaces despite vibration and weather. Premium vinyl tapes remain firmly in place and readable for years — a key safety and maintenance advantage.

Commercial Applications of Vinyl Labels

While vinyl is prized for industrial use, it’s equally valuable in commercial settings where aesthetics meet durability.

Retail and Product Branding

For businesses that package products exposed to moisture or friction, vinyl labels ensure a premium presentation that lasts through shipping and handling. Whether glossy or matte, vinyl provides a smooth finish that enhances color vibrancy and brand consistency.

Office and Warehouse Organization

Commercial warehouses and offices benefit from vinyl’s longevity on shelves, bins, and asset tags. Labels printed with a thermal transfer printer remain crisp and easily scannable, improving workflow and inventory accuracy.

Safety and Compliance Signage

Vinyl is a preferred substrate for OSHA-compliant safety signage due to its tear resistance and bold color reproduction. It can be laminated or printed directly for lasting visibility in high-traffic areas.

Choosing the Right Vinyl Label for Your Application

Vinyl labels vary by adhesive type, finish, and printing method. Understanding these options ensures optimal performance and cost-efficiency.

Adhesive Type

Permanent adhesives are ideal for equipment and signage that must remain in place for years. Removable adhesives suit temporary applications, allowing labels to be peeled off cleanly without residue.

Finish and Texture

Matte finishes minimize glare in bright industrial lighting, while glossy finishes enhance color vibrancy for retail or branding. Some specialty vinyl labels feature a textured surface for better grip in high-touch areas.

Printing Compatibility

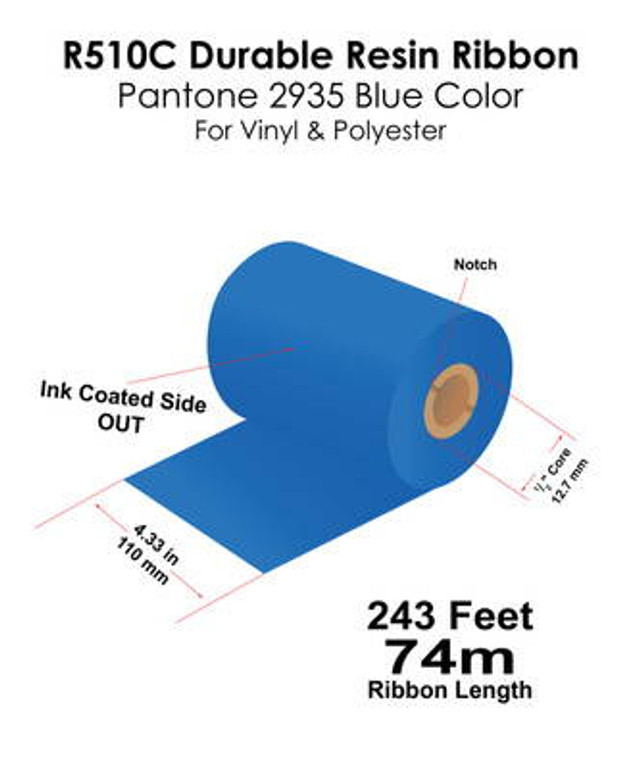

Not all printers can handle vinyl’s durability. Always match the label with a compatible printer and ribbon combination. For example, the Vinyl 4.33” x 243 ft R510C Blue Durable Resin Ribbon pairs perfectly with Zebra, Brother, and GoDEX printers, delivering fade-resistant results suitable for industrial conditions.

Why Vinyl Beats Alternatives in Longevity and Performance

Many businesses initially choose paper or polypropylene labels to save on costs. However, when reprints, replacements, and damage are factored in, vinyl offers the best long-term value.

Vinyl labels last 3–5 times longer than standard materials under identical conditions. Their ability to conform to uneven surfaces and maintain adhesion under pressure makes them indispensable for durable labeling solutions.

In short, vinyl isn’t just stronger — it’s smarter. It reduces reprints, extends product life cycles, and preserves critical information, which ultimately saves both time and money.

Maintenance and Care for Vinyl Labels

Even the toughest labels benefit from proper handling and maintenance. To maximize performance:

Store Labels Properly

Keep vinyl labels in a cool, dry area, away from direct sunlight. Extreme temperatures or humidity can affect adhesive performance.

Clean Application Surfaces

Before applying, ensure surfaces are free from dust, oil, or moisture. A clean surface ensures full contact and prevents bubbling or peeling.

Use the Correct Print Settings

When printing on vinyl, adjust printhead heat and pressure for optimal transfer. Using resin ribbons guarantees superior adhesion and scratch resistance.

Apply at the Right Temperature

For best adhesion, apply vinyl labels at room temperature (between 18°C and 25°C). Cold surfaces can cause adhesives to harden prematurely, weakening the bond.

Label Customization and Branding Potential

Vinyl labels aren’t just functional; they’re also highly customizable. With modern digital printing technologies, it’s easy to combine durability with branding excellence.

At DuraFast Label Company, we help clients design custom vinyl labels tailored to their environment, product, and brand. You can specify color, size, adhesive strength, and finish — all while maintaining the toughness vinyl is known for.

From full-color company logos to serialized barcodes and compliance icons, vinyl offers creative flexibility without compromising on longevity.

For industrial equipment, durable asset labels with your logo or QR code reinforce professionalism while streamlining maintenance tracking.

Environmental and Sustainability Considerations

While vinyl is a synthetic material, advancements in recycling have made it a more sustainable choice than ever. Many industrial vinyl products are now made using eco-conscious manufacturing processes that reduce emissions and waste.

Additionally, because vinyl lasts longer, fewer reprints and replacements are needed — indirectly reducing total material consumption.

At DuraFast, we prioritize suppliers who balance performance with sustainability, ensuring your labeling solution aligns with modern environmental standards.

Real-World Example: Vinyl in Action

A logistics company in Ontario faced repeated issues with peeling and fading barcode labels during outdoor loading operations. Paper and polypropylene labels couldn’t handle temperature changes and moisture exposure.

After switching to vinyl labels paired with resin ribbons, label lifespan increased from two weeks to over a year. The improved durability cut reprinting costs by 40% and significantly reduced barcode scanning errors — proving vinyl’s unmatched resilience in harsh environments.

This story mirrors what we’ve seen across industries: once companies experience the consistency of vinyl, they rarely switch back.

Integrating Vinyl Labels with Your Workflow

Vinyl labeling works best when paired with the right equipment and processes. Our team at DuraFast Label Company helps clients in Canada integrate label creation, printing, and application into seamless workflows.

For example:

- Using a GoDEX G530 or TSC thermal printer with resin ribbons ensures long-lasting prints.

- Automated label applicators speed up placement on metal, plastic, or tubing surfaces.

- Label design software allows quick customization and serialization for asset tracking.

The result is a faster, more reliable labeling process that boosts productivity and professionalism.

When to Choose Vinyl Over Other Materials

Vinyl is ideal for:

- Equipment labels requiring resistance to heat, water, or chemicals

- Safety and compliance signage exposed to harsh environments

- Marine or automotive labeling where weather resistance is critical

- Long-term product identification in warehouses or production facilities

When the cost of label failure outweighs the savings of cheaper materials, vinyl is always the right choice.

DuraFast Label Company: Your Partner in Industrial Labeling Excellence

At DuraFast Label Company, we specialize in helping businesses in Canada identify the right materials for their applications. Whether you need labels for harsh outdoor environments, lab samples, or heavy-duty machinery, we provide high-performance vinyl solutions that meet your durability and compliance requirements.

Explore some of our top-selling options:

- Dymo 18445 Rhino ¾” White Vinyl Tape— excellent for cable marking and electrical labeling.

- Vinyl Label Tapes– available in widths from 1 inch to 8 inch wide

- Vinyl 4.33” x 243 ft R510C Blue Durable Resin Ribbon— perfect for high-resistance printing.

- MAX Letatwin LM-TU432L2 Vinyl Tube Roll— ideal for industrial and construction labeling.

We take pride in offering more than products — we deliver solutions. Our experts can help you identify the best label type, printer, and printing supplies for your exact operational environment.

Vinyl Label Printers and Vinyl Label Tapes Available at DuraFast Label Company

Choosing the right vinyl labels is only part of the equation — pairing them with compatible printers and high-quality vinyl tape ensures maximum durability and print performance. At DuraFast Label Company, we supply a full range of desktop vinyl label printers designed specifically for industrial and commercial environments.

Browse our complete lineup here:

We offer leading models such as the GoDEX GE330 Thermal Transfer Vinyl Tape Label Printer and the GoDEX G530 Thermal Transfer Vinyl Label Printer, both engineered to produce crisp, long-lasting prints on vinyl materials. For businesses that need highly customized shapes and precision-cut labels, we also carry the MAX Bepop Vinyl Printer and Cutter, an all-in-one system ideal for safety signage, equipment labels, and custom industrial graphics.

In addition, DuraFast provides a wide selection of vinyl label tapes compatible with these printers, ensuring dependable performance for every application. Explore our full tape collection:

We stock a comprehensive range of vinyl label tapes for the GoDEX GE330 and G530 printers, allowing you to match the perfect size, color, and adhesive strength to your project requirements.

If you’re ready to enhance your industrial labeling process, contact DuraFast Label Company today to discuss your project and get professional recommendations.