How to Incorporate Custom Thermal Transfer Labels into Your Branding

10th Dec 2025

Every product tells a story—but few businesses realize that the label is the first chapter. Before customers experience your product, they see your label. It’s the visual handshake that communicates quality, trust, and consistency. This is where custom thermal transfer labels come into play.

At DuraFast Label Company, we understand that great branding isn’t just about logos and packaging—it’s about the details that last. With the precision and durability of thermal transfer printing, your labels don’t just look good—they endure. Whether used on cosmetics, electronics, food containers, or industrial tools, thermal transfer technology ensures that your brand remains visible and intact, even under harsh conditions.

Custom thermal transfer labels are more than an operational choice—they’re a strategic branding tool. Let’s explore how they work, what makes them ideal for brand consistency, and how to seamlessly integrate them into your overall visual identity.

Understanding Thermal Transfer Labels

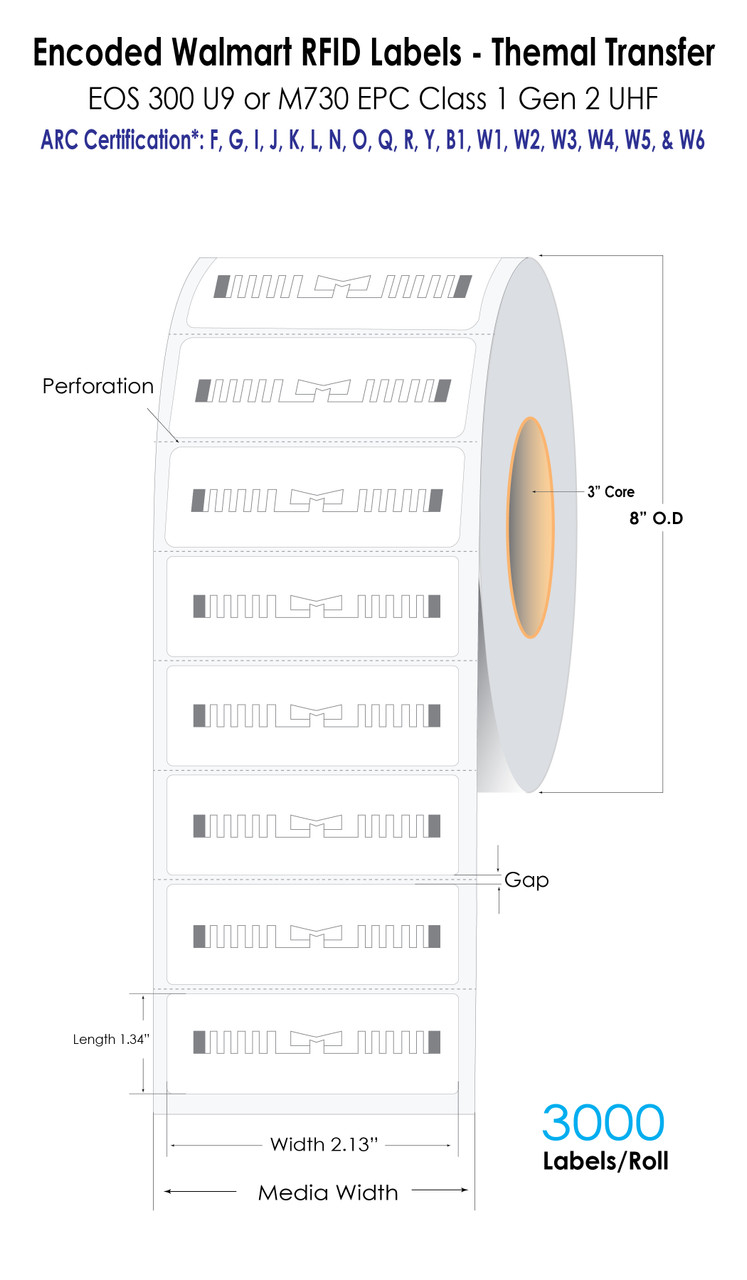

Thermal transfer printing uses a ribbon coated with wax, resin, or a combination of both. When the printer’s thermal head heats up, the ink from the ribbon is transferred onto the label material. The result is a crisp, durable, and high-resolution print that can withstand exposure to sunlight, moisture, oils, and chemicals, such as the Walmart Encoded RFID Labels.

This makes thermal transfer labels for sale ideal for businesses that need long-lasting prints that don’t smudge, fade, or peel—especially those in logistics, manufacturing, and retail.

Key Benefits of Thermal Transfer Labels

- Durability: Labels maintain integrity even in extreme heat or cold.

- Professional Appearance: Produces consistent, high-resolution text and graphics.

- Versatility: Works on a variety of materials—paper, polyester, vinyl, and polypropylene.

- Customizability: Perfect for branding applications where unique designs or colors are essential.

When paired with a reliable printer, like those available at DuraFast Label Company, these labels become the foundation for high-quality, branded product presentation.

Why Custom Thermal Transfer Labels Are Ideal for Branding

Your label is more than product information—it’s a visual asset. It conveys brand credibility and builds trust at the point of purchase. Here’s why custom thermal transfer labels have become the go-to choice for brand-conscious companies.

1. Consistency Builds Recognition

Brand consistency is vital. Thermal transfer technology ensures every label—whether printed today or six months later—matches perfectly in color, tone, and sharpness. This consistency across packaging reinforces brand recall and customer confidence.

2. Durability Strengthens Perception

A peeling or faded label can ruin the customer experience. Thermal transfer labels resist abrasions, moisture, and UV exposure, ensuring your brand remains pristine long after purchase. For businesses selling outdoor or industrial products, this durability translates directly into perceived product quality.

3. Customization Boosts Brand Identity

Every industry has different requirements—some need regulatory compliance, while others prioritize aesthetics. Thermal transfer printing allows for customizable materials, finishes, and adhesives, so you can tailor your label to align with your visual identity and market positioning.

4. Compatibility Across Multiple Applications

From small retail jars to bulk industrial drums, thermal transfer labels adapt effortlessly. Whether you’re printing sleek product labels or rugged warehouse tags, the technology supports your branding objectives while maintaining efficiency.

Designing Custom Thermal Transfer Labels for Brand Impact

A custom label should do more than inform—it should inspire. When designing your label, balance aesthetics with functionality to ensure it performs as well as it looks.

1. Choose the Right Material

Your material sets the tone for how customers perceive your brand.

- Paper labels offer an eco-friendly, affordable option for dry goods and packaging.

- Polyester or polypropylene labels are ideal for high-end or industrial products needing resilience.

- Vinyl labels in Canada provide flexibility and durability, perfect for outdoor use or curved surfaces.

2. Use Finishes Strategically

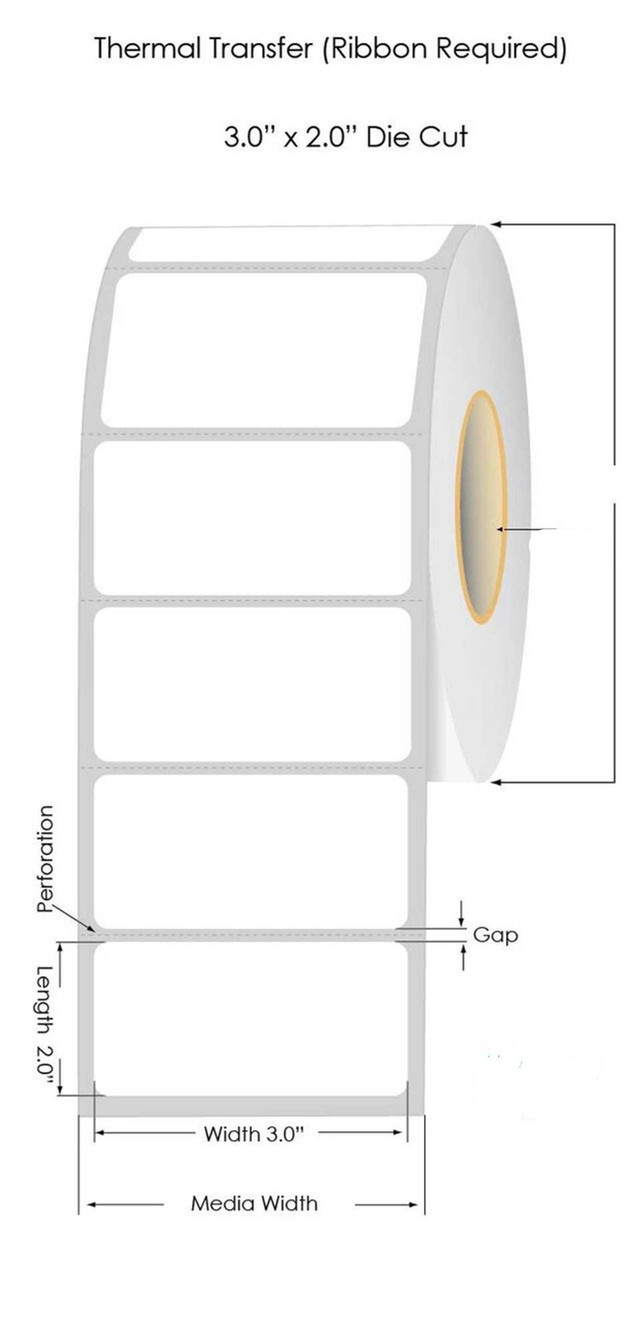

Matte, gloss, or satin finishes each tell a different story, such as the Thermal Transfer 3" x 2" Semi Gloss Paper Labels. Matte exudes elegance and minimalism; gloss enhances color vibrancy; satin offers a professional balance between both. The right finish amplifies your design and reflects your brand personality.

3. Incorporate Branding Elements Thoughtfully

Your logo, typography, and color palette should be used consistently. Ensure readability—barcodes, expiration dates, and serial numbers must remain clear, even when incorporating design features.

4. Optimize for Printer Compatibility

Before finalizing your design, confirm it aligns with your printer’s resolution and ribbon type. For instance, wax/resin ribbons are ideal for semi-durable applications, while full resin ribbons are best for harsh environments.

Applications Across Industries

Custom thermal transfer labels can elevate branding across nearly every sector:

- Food & Beverage: Showcase freshness, origin, and compliance while maintaining legibility in cold storage or high-humidity conditions.

- Cosmetics & Beauty: Highlight brand prestige with smudge-proof, high-resolution designs.

- Electronics: Include logos and compliance information that remain visible under heat or friction.

- Healthcare: Ensure patient safety and traceability with scannable, durable labels.

- Industrial Manufacturing: Use for machine tags, safety warnings, and durable product identification.

- Apparel: Integrate wash care label printersto maintain brand integrity through laundering.

These applications demonstrate how custom thermal transfer labels blend visual appeal with reliability—a key to brand success.

Best Practices for Implementing Custom Labels

Implementing custom labels effectively requires thoughtful execution. Here’s how to do it right.

1. Define Your Branding Goals

Start by identifying what you want your labels to communicate—luxury, sustainability, innovation, or durability. These attributes should influence your design and material choices.

2. Collaborate with a Label Expert

Partnering with a trusted supplier like DuraFast Label Company ensures your labels are designed with the correct specifications for your printer, ribbon, and application.

3. Test Before Full Production

Always print a small batch first. Evaluate how your design performs under actual usage conditions—exposure to moisture, temperature changes, or handling. Adjust settings or materials as needed before mass production.

4. Consider Adhesive Strength

Not all adhesives are equal. Choose permanent adhesive for long-term branding and removable options for temporary or reusable applications.

5. Plan for Scalability

As your business grows, you’ll need to replicate label quality across product lines and production sites. Thermal transfer printing guarantees consistency at scale, ensuring brand alignment everywhere your products appear.

The Role of Thermal Transfer Printers in Branding

Your printer is the bridge between your design and the finished label. DuraFast offers a range of models—from desktop to industrial—engineered for precision branding.

- The GoDEX G530 Thermal Transfer Barcode Printer (view here) provides 300 dpi resolution for sharp, professional output.

- For industrial applications, the GoDEX ZX1300i delivers durability and speed, ideal for large-scale branding tasks.

- Compact setups can rely on the Brother TD4420TN for dependable, high-quality prints.

Using high-performance hardware ensures that your label design translates accurately onto every material.

Integrating Labels into a Broader Branding Strategy

To make the most of your custom thermal transfer labels, align them with your overall brand ecosystem.

- Consistency Across Touchpoints: Your label design should match digital branding—same fonts, colors, and logo placement.

- Storytelling Through Design: Use labels to tell your brand’s story—heritage, craftsmanship, or sustainability.

- Seasonal & Limited Editions: Create special label runs to enhance exclusivity and customer engagement.

- Data-Driven Customization: Incorporate barcodes or RFID tags for smart packaging solutions, enhancing traceability while reinforcing a tech-forward image.

Maintaining Label Quality Over Time

A strong brand doesn’t fade—and neither should your labels.

Keep your prints consistent with these maintenance tips:

- Use compatible ribbons and label stock. Inferior materials can compromise print quality and adhesive performance.

- Store rolls properly. Keep labels in a cool, dry place to prevent discoloration or curling.

- Clean printheads regularly. Dust or residue can cause uneven prints or streaks.

- Monitor environmental exposure. Choose label materials rated for your specific use conditions, especially for products stored outdoors or in freezers.

Bringing It All Together: Branding That Lasts

Incorporating custom thermal transfer labels into your branding strategy is more than a design decision—it’s a commitment to quality, consistency, and customer trust. By combining durable materials, precision printing, and creative design, you can transform every label into a miniature ambassador for your brand.

At DuraFast Label Company, we help businesses achieve exactly that. We supply high-quality thermal label printers, ribbons, and materials tailored to your needs, ensuring every print captures your brand at its best. Whether you’re creating luxury packaging, industrial-grade identification, or retail-ready labels, our solutions make your branding last—literally.

If you’re ready to elevate your product presentation with reliable, beautiful, and durable labels, contact DuraFast Label Company today to explore the perfect solution for your business.