A Complete Guide to Using Label Applicators in Manufacturing

8th Dec 2025

In today’s manufacturing world, automation isn’t optional — it’s essential. From assembly lines to packaging, every second counts. And when it comes to labeling, manual methods simply can’t keep up. That’s why many manufacturers are turning to label applicators — devices that automatically place labels onto products, packaging, or containers with unmatched accuracy and speed.

At DuraFast Label Company, we’ve seen how even a single label applicator can revolutionize operations. These systems not only enhance efficiency but also eliminate labeling errors, ensuring products meet quality and compliance standards every time. Whether you’re labeling bottles, pouches, or boxes, an automated applicator integrates seamlessly into your production line to deliver consistency at scale.

This guide breaks down how label applicators work, their benefits, types, setup process, and how they can completely transform your manufacturing workflow.

Understanding Label Applicators

A label applicator is an automated machine that applies pre-printed or print-and-apply labels directly onto products or packaging surfaces. It’s a crucial piece of industrial automation that bridges the gap between printing and packaging.

Instead of workers peeling and sticking each label manually — a repetitive, error-prone process — applicators handle the job at lightning speed, often labeling hundreds or even thousands of products per hour.

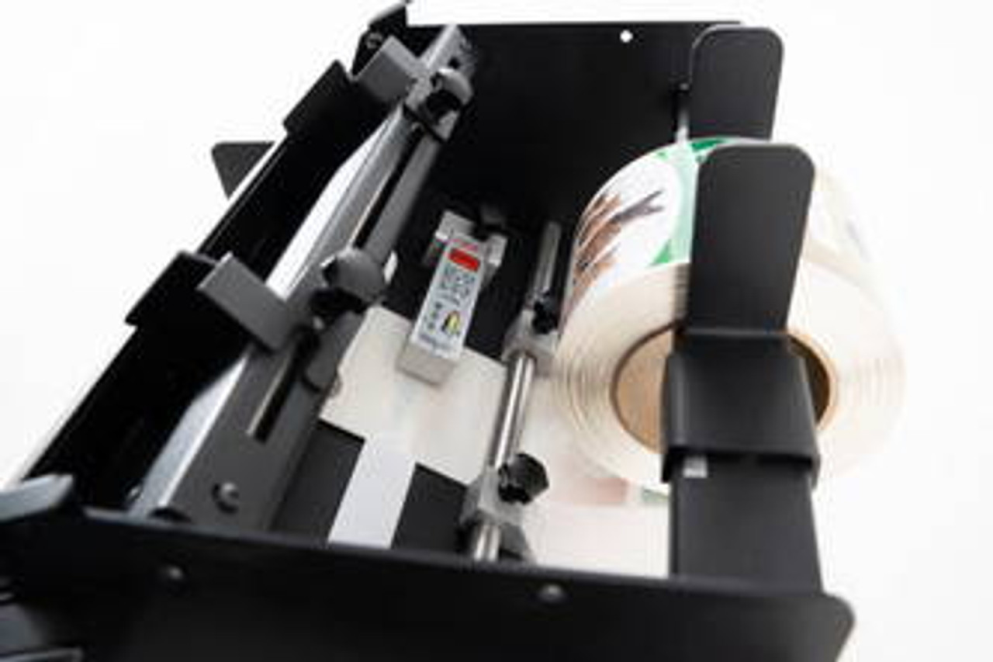

Core Components

Every applicator includes:

- Unwind and Rewind Spools: To feed label rolls and collect liners.

- Applicator Head: Dispenses the label precisely on the surface.

- Sensors and Controls: Ensure correct alignment, timing, and pressure.

- Integration Mechanisms: Connect to conveyors, printers, or other packaging systems.

Together, these components create a seamless system that ensures each label lands in the right spot — straight, centered, and secure.

Why Label Automation Matters in Manufacturing

Labeling might seem like a small part of production, but it has major implications. Labels carry vital information — barcodes, product details, batch codes, compliance markings — all of which must be accurate and legible.

In high-output facilities, even small mistakes can create expensive ripple effects. Mislabeling can cause product recalls, fines, or brand damage. Manual labeling also slows production, introduces inconsistency, and drives up labor costs.

The ROI of Automation

By automating labeling:

- Production speeds increase dramatically.

- Errors and waste are reduced.

- Labor can be reallocated to higher-value tasks.

- Packaging lines become more predictable and scalable.

That’s why label applicators have become a cornerstone of lean manufacturing.

Types of Label Applicators

Different manufacturing setups require different types of applicators. Choosing the right one depends on your packaging style, speed requirements, and product dimensions.

1. Flat-Surface Applicators

Ideal for boxes, pouches, and flat packaging materials, these applicators ensure smooth, wrinkle-free placement on large or rigid surfaces. The Afinia AF200 Flat Package Label Applicator is a standout in this category, capable of handling a wide range of label sizes and substrates with precision.

2. Pouch and Bag Applicators

For flexible packaging like pouches or bags, a gentle yet firm application system is needed. The Afinia AP200 Pouch Label Applicator uses adjustable rollers to apply labels evenly without creasing, making it perfect for coffee bags, snack packaging, or cosmetic pouches.

3. Print-and-Apply Systems

These systems print labels on demand before immediately applying them to products — ideal for dynamic environments where data changes frequently (e.g., barcodes, lot numbers, or expiration dates).

4. Wraparound Applicators

Common in beverage, pharmaceutical, and cosmetic industries, wraparound applicators apply labels 360° around cylindrical containers like bottles or tubes, ensuring perfect alignment every time.

5. Corner-Wrap and Dual-Panel Applicators

These apply labels to two adjacent sides of boxes — often used for shipping or pallet labeling. They ensure barcodes are visible from multiple angles during logistics scanning.

Each type of applicator serves a unique production need, and selecting the right model can make the difference between smooth integration and recurring downtime.

How Label Applicators Work

Despite their technical complexity, label applicators follow a simple process:

- Label Feeding: The roll unwinds through the applicator system.

- Sensing and Alignment: Optical or mechanical sensors detect the product’s position.

- Label Dispensing: The applicator head peels the label off its liner and presses it onto the surface using air pressure, a roller, or a tamp mechanism.

- Rewinding: The used liner is wound onto a take-up reel.

Each step is synchronized with conveyor motion, ensuring continuous flow without stopping the line. Modern applicators can also adjust in real-time for variable product sizes, surface textures, and label designs.

Benefits of Using Label Applicators in Manufacturing

1. Consistency and Accuracy

Manual labeling often leads to uneven placement, creases, or misalignment. Automated applicators guarantee uniform label positioning across thousands of units, maintaining your brand’s visual consistency.

2. Increased Throughput

Label applicators apply labels in seconds, enabling high-speed production lines to maintain momentum. When paired with high-performance printers, production capacity can double or even triple.

3. Reduced Labor Costs

What once required several staff members can now be managed by one operator supervising the system. This doesn’t just save wages — it frees up your workforce for higher-value tasks.

4. Improved Compliance

In industries where labeling accuracy is regulated (like food, pharmaceuticals, or electronics), automation eliminates human error, ensuring every product meets compliance and traceability standards.

5. Integration with Digital Systems

Label applicators can be networked with ERP, WMS, or MES systems, allowing for automatic label generation, verification, and batch tracking — a key advantage in smart manufacturing.

Integrating Label Applicators into Production Lines

Adding a label applicator to your workflow doesn’t necessarily require a complete redesign. Modern systems are modular and can adapt to existing conveyors, packaging tables, or bottling lines.

Installation and Calibration

We assist clients through every phase — from mechanical setup to fine-tuning label alignment. Applicators like the Afinia AF200 feature intuitive touchscreen controls for easy configuration and repeatable accuracy.

Synchronization

Applicators must sync precisely with product movement. Using sensors and encoders, the system ensures labels are applied at the exact moment each product passes under the applicator head.

Operator Training

Though mostly automated, applicators still require human supervision. Operators monitor sensor alignment, roll changes, and basic maintenance. At DuraFast, we provide in-depth training so your staff can confidently manage the system with minimal downtime.

Maintenance and Troubleshooting

To maximize uptime, routine maintenance is essential.

Keep applicators clean and free of adhesive residue. Replace worn rollers and check sensor calibration regularly. High-quality labels and liners prevent sticking and reduce static buildup.

If a label misalignment occurs, recalibration typically resolves it. Modern applicators include diagnostic interfaces that alert operators to potential issues before they cause stoppages.

At DuraFast, we recommend preventive maintenance every 3–6 months, depending on production volume.

Common Challenges and How to Overcome Them

Even the most advanced systems encounter challenges — usually minor ones that can be prevented with preparation.

Static Electricity

Dry environments create static buildup that causes labels to misfeed. Anti-static brushes or humidifiers can solve this easily.

Label Curling

If stored improperly, labels can curl and jam applicators. Keeping label rolls sealed in a controlled environment avoids feeding problems.

Inconsistent Adhesion

Dust or oil on product surfaces prevents labels from sticking. Cleaning surfaces before application ensures strong adhesion.

With proper handling, calibration, and cleaning, applicators can run continuously with minimal downtime for years.

Automation and Industry 4.0: The Future of Labeling

The next evolution in labeling is fully connected automation. Applicators are becoming smarter, integrating real-time sensors, cameras, and IoT connectivity.

These innovations allow operators to monitor label performance remotely, receive predictive maintenance alerts, and ensure every product is labeled correctly before shipment.

At DuraFast Label Company, we partner with manufacturers in Canada adopting Industry 4.0 systems — helping them connect label applicators to cloud dashboards for data-driven production visibility.

Automation isn’t just about speed anymore; it’s about intelligence, precision, and control.

Environmental and Cost Efficiency

Automated labeling systems minimize waste by ensuring perfect placement and reducing rejected labels. By switching from manual application to automation, businesses save not only time but also materials.

Reusable cores, recyclable liners, and precise labeling contribute to sustainability goals — aligning your production with eco-conscious standards.

Real-World Example: Boosting Output with Applicator Integration

A mid-sized packaging company approached us, struggling with manual labeling inefficiencies. Their team of five could only label 1,000 units per shift. Labels were often misaligned, and productivity was limited.

After installing the Afinia AP200 Pouch Label Applicator, output soared to 4,500 labels per shift with only one operator. Labor costs decreased, consistency improved, and quality checks became effortless.

This transformation not only reduced overhead but also allowed the company to take on larger contracts with confidence.

How to Choose the Right Label Applicator

When choosing an applicator, consider:

- Product Type: Flat, curved, flexible, or cylindrical surfaces.

- Label Size: Larger labels may require wider rollers and different feed mechanisms.

- Speed Requirements: Match applicator throughput to your packaging line’s speed.

- Integration Needs: Choose between standalone or inline systems.

- Maintenance Accessibility: Look for easy-change rollers and intuitive touchscreens.

DuraFast’s experts assess your operation’s layout, production volume, and labeling requirements before recommending the most efficient setup.

Why Choose DuraFast Label Company

At DuraFast Label Company, we do more than supply equipment — we provide end-to-end labeling solutions. We understand that every manufacturing setup is unique, so we tailor systems that meet both technical and operational needs.

Our range includes:

- Afinia AF200 Flat Package Label Applicator– built for precision on flat boxes and cartons.

- Afinia AP200 Pouch Label Applicator– designed for flexible packaging and small-batch labeling.

We help clients integrate these systems seamlessly with thermal printers, inkjet systems, and ERP software to build automated workflows that scale efficiently.

Expanding Your Labeling Options: Bottle, Flat, and Pouch Applicators from Afinia

Manufacturers looking for a reliable and scalable labeling solution often turn to Afinia’s lineup of high-performance applicators. As part of our full catalog of industrial label applicators,

DuraFast Label Company also offers the most popular bottle-labeling system used across food, cosmetic, nutraceutical, and craft beverage industries — the Afinia A200 Semi-Automatic Bottle Label Applicator.

The Afinia A200 is engineered to apply single or front-and-back labels to cylindrical containers with precision and repeatability. Its semi-automatic design makes it ideal for small to mid-sized manufacturers who need professional, consistent bottle labeling without the complexity of a fully automated system. With adjustable guides, intuitive controls, and repeatable accuracy, it delivers clean, wrinkle-free labels on bottles, jars, tubes, and canisters — significantly improving productivity over manual application.

DuraFast also carries the full range of Afinia label applicators, including:

- Afinia AF200 Flat Package Label Applicator – perfect for cartons, boxes, and rigid packaging.

- Afinia AP200 Pouch Label Applicator – built for flexible packaging such as pouches, bags, and sachets.

- Afinia A200 Bottle Label Applicator – the go-to solution for cylindrical containers in beverage, cosmetics, and chemical production.

By offering applicators for bottles, pouches, and flat packages, DuraFast helps manufacturers create a fully optimized labeling workflow tailored to their unique product mix. Whether you are labeling jars of cosmetics, bags of coffee, boxed products, or nutritional supplements, our Afinia lineup ensures a seamless integration into any production environment.

Building Smarter, Faster Labeling Systems

Labeling automation is no longer a luxury — it’s a necessity for manufacturers competing in today’s fast-moving markets. With the right label applicators, you can eliminate manual errors, boost throughput, and achieve precise, repeatable labeling at an industrial scale.

At DuraFast Label Company, we specialize in helping businesses in Canada choose and implement labeling systems that transform operations. Whether you need a compact tabletop unit for small runs or a high-speed inline solution, we have the tools and expertise to match your goals.

Explore our full range of label applicators today, or contact us for tailored recommendations and professional setup support. Together, we’ll help you create a labeling process built for speed, accuracy, and success.