How to Create Clear Electrical Panel Labels Easily

Key Highlights

-

A clear electrical panel labeling system is key for electrical safety at work. It is needed by the National Electrical Code.

-

Good panel labeling helps you find different circuits fast. This can cut downtime and can stop some mistakes when people do repairs or when there is an emergency.

-

If you follow best practices for your panel labeling, you are following Canadian safety rules and keeping electrical safety at the right level.

-

Use strong stuff like polyester, vinyl, and heat-shrink tubing for your electrical labels. These will help to keep your electrical labels clear and tough, even if your place gets rough.

-

You can use professional label makers including the MAX Letetwin and Epson LabelWorks. These label makers are able to handle all your electrical panel labeling jobs and will help you with electrical labeling that is both durable and reliable.

Introduction

Clear and correct labels on your electrical panel are very important for electrical safety. A neatly labeled electrical panel helps you turn off power quickly. This can help in case of an emergency. A good electrical panel labeling system also helps you find and fix problems faster. It helps you work on the electrical system safely.

If you are an electrician, work as a facility manager, or you are a homeowner, you will want to know about best practices for panel labeling. This guide will show the main standards, tools, and tips for electrical panel labeling. A good labeling system lets you and other people read your electrical panel clearly and use it right. It improves electrical safety for everyone working with your electrical system.

The Importance of Accurate Electrical Panel Labeling in Canada

In Canada, panel labeling is needed for workplace safety. You must have clear information for your electrical system. Proper labeling lets people at work know what is inside each panel. This helps you avoid electrical hazards. If a problem or emergency happens, quick and clear labeling makes it easy for people to act fast. When there is not good labeling, everyone can get hurt. It also makes it hard to keep the workplace safe.

For electricians and first responders, it is important to have a clear panel. A panel that is marked helps people find the correct breaker fast. This way, you or someone else can turn off the right breaker at once. This helps keep everyone safe. It also stops things or places from getting hurt or damaged. A panel that is clean and easy to read also helps follow Canadian safety rules.

Why Effective Labeling Ensures Safety and Compliance

Yes, there are some rules and laws you have to follow when you label an electrical panel. Good labeling is the first step for keeping people safe. This is very important.

If a fire happens or there is a problem with the power, knowing what breaker to turn off can save lives. When you put clear and easy labels on the electrical panel, it lets you or others see which breaker goes to which part. Good labeling can help stop a shock or keep a fire from getting worse. This way, all people feel safer.

In Canada, you have to follow the Canadian Electrical (CE) Code. This code is close to the National Electrical Code (NEC) that is in use in the United States. According to the code, every electrical panel must have a directory. This directory must show what every circuit does in it. The rules around labeling are there to keep everyone safe. Electrical Safety Foundation International (ESFI) said there were more than 1,500 injuries from electrical work in just one year. If you practice electrical safety the right way, like by following proper labeling and having a clear directory in the panel, you help make people safer and lower that number of injuries. [Source: https://www.esfi.org/workplace-safety/workplace-injury-and-fatality-statistics/]

If you do not follow the rules, you might break the law and put people at risk. When you make sure your home or building meets the codes, you do more than avoid fines. You also help keep the place safe for everyone. Good electrical labeling is a key part in any strong safety plan. Labeling is important and should not be left out if you want the area to be safe for all.

Common Challenges Faced Without Proper Labeling

Dealing with an electrical panel that is not labeled or if it is hard to read can make things tough. For homeowners, this situation can be confusing and feel not safe. When you do not know what switch goes to which area, even simple fixes can take a lot more time. This can lead to more downtime at your home and at work. People working on the electrical panel also face more risk. A clear electrical panel with labels is needed to keep everyone safe and help save time.

Imagine you try to fix a tripped breaker and do not know what it controls. You may need to guess which one to reset. This brings a risk of errors. It can also make power outages go on longer than they should. People who work with breakers may lose time and do less work. For homeowners, these issues with breakers can be trouble in the home.

The most common challenges you might face include:

-

Increased Risk of Electrical Hazards: If circuits are not clearly marked, there is a good chance that someone may work on a live circuit without knowing. This can lead to big danger and more electrical hazards.

-

Costly Downtime: Without proper labels, you have to spend more time and energy to figure out which circuit is which. This can slow down the work. The job will take longer and lead to more downtime.

-

Confusion During Emergencies: If there is an emergency, it can be hard to know which power to turn off. This can make the situation worse and bring more risks.

-

Compliance Violations: If the circuits are not labeled the right way, you may not follow the laws and rules. This can lead to serious problems with compliance.

Understanding Standard Requirements for Electrical Panel Labels

To make sure your electrical panel labels work in the right way, you need to follow the rules set by industry regulations. These guidelines help you build an electrical system that is safe, easy to use, and looks the same as other systems. Rules from groups like the CSA Group in Canada, NEC, and ANSI are set up to give you the best results. They are often required by law.

A comprehensive labeling system is about more than just the main panel. It should have labels on all the circuit breakers. There need to be labels on every piece of wiring, the terminal blocks, and the disconnect switches as well. The sections below will tell you which codes to use. You will also learn the right way to format your labeling so people can read and understand it easily.

Canadian Codes and Safety Regulations to Follow

In Canada, you have to follow the rules in the Canadian Electrical Code, called the CE Code, for electrical installations. The CSA Group makes and releases this code. People in most parts of the country use the CE Code as the law for this work. The code tells you how to label electrical equipment. This helps to keep people safe. It also says that you need to mark every circuit with what it is used for.

Along with the CE Code, it is a good idea to follow the rules from other well-known groups. These groups help people make the workplace safer. They tell us what a safety label should look like, what color it should be, and how long it should stay up. This helps to make workplace safety better for everyone.

Here are the main rules and groups that you need to know about.

|

Regulatory Body |

Relevance to Electrical Labeling |

|---|---|

|

CSA Group (CE Code) |

Sets the legal standard for electrical installations and labeling in Canada, requiring clear and specific circuit identification. [Source: https://www.csagroup.org/store/product/2428850/] |

|

NFPA (NEC) |

The National Electrical Code provides the benchmark for electrical design and safety in the U.S., and its principles are widely adopted as best practices. [Source: https://www.nfpa.org/codes-and-standards/all-codes-and-standards/list-of-codes-and-standards/detail?code=70] |

|

OSHA |

Focuses on workplace safety, requiring warning signs and tags to alert employees to electrical hazards. [Source: https://www.osha.gov/laws-regs/regulations/standardnumber/1910] |

|

ANSI |

The American National Standards Institute provides detailed guidelines on the design of safety signs, including signal words, colors, and symbols. |

Recommended Label Formats and Placement Guidelines

After you know the rules, you then need to use clear labels in your electrical panel. Put each label on the right spot by the correct breaker. It is important to stay detailed. You have to use the same style for all the labels.

Do not use labels like "Outlets" or "Lights." These words are too general. Use clear labels instead, such as "Kitchen Counter Outlets" or "Master Bedroom Lights." This will help you, and anyone else, see what every circuit breaker controls.

Where you place your labels really matters for your electrical system. Put every label next to its corresponding breaker. This helps you and other people avoid any mix-ups or confusion. You can usually find the directory inside the panel door. The directory should be neat and simple to read. It can help you look over the full electrical system quickly.

Follow these guidelines for the best results:

-

Use a durable label maker to make labels that are easy to read and last a long time.

-

Put each label in the same spot. Place it above, below, or next to its breaker.

-

Write short and clear descriptions for every circuit in the electrical system.

-

Do not cover any information from the company or the safety warnings that are already on the panel.

-

Update the directory on the panel right after you make any changes to the electrical system.

Types of Electrical Panel Labels and Materials Available

Choosing the right material for electrical labeling matters a lot. It makes your labeling last longer and easy to read. The spot where you place the panel will change what you need. Your labels should be durable. This means they have to stand up to moisture, heat, and chemicals. It keeps them from fading or peeling off.

Common things you can use with your label maker are vinyl and polyester. These materials be strong, and they also bend well. They work for many jobs with labeling. If you have wires to label, you should use heat shrink tubes for that job. A good label maker will let you use all these materials. So you get to do a lot of different kinds of labeling.

Polyester, Vinyl, Heat Shrink, and Other Label Media

There are many choices when it comes to electrical panel labels. The one you pick really depends on what you need. Polyester labels work well for panel labeling. They are best if you put them on a flat surface. These labels last for a long time. They can deal with things like heat or chemicals. This makes them good for tough places, like a factory. You can buy these labeling items at a store that sells electrical supplies. You can also get them online.

Vinyl labels are a good choice because they are flexible. You can use them on electrical conduits or wiring. They work well on curved and uneven surfaces, too. The vinyl keeps out moisture and stops UV light from getting in. You can use these labels inside or outside. Their adhesive is strong, so the labels stay in place on wiring, conduits, or any area you choose. They last for many years without coming off.

When it comes to electrical labeling, heat shrink tubing is something most professionals use first. You put text on a piece of this special tube. Then, you slide it over your wire and use heat. The tube will shrink and fit tight around the wire. This makes a marker that is strong and does not come off easy. It can handle wear and does not tear or come loose. Using heat shrink tubing gives you a clean and neat way of labeling. The marker stays in place over time. You can get all these labeling items and the printers to use with them at DuraFast Label Company.

Which Label Tape Is Most Durable for Harsh Environments?

In places that can be hard on things, like factories or outdoor areas, paper labels will not last. For your electrical equipment, you need labels that stay strong and clear to read for a long time. What is the most durable label material? For most jobs, polyester is one of the top choices.

Polyester labels are built to handle scratching, hard chemicals, and very high or low temperatures. They work well in tough spots. If you need something to last even longer, like for rating plates or asset tags that face bad weather and rough use, try photosensitive anodized aluminum such as Metalphoto®. This kind can last for more than 20 years. It is very strong and something you can count on for a long time.

When you need to choose a label that will last, make sure it has these features:

-

Resistance to moisture, oil, and chemicals: The label does not get smudged or worn out. It can handle wet places and oily things.

-

High-tack adhesive: The label sticks well no matter if it’s hot or cold. It does not come off easily.

-

Abrasion resistance: Your text stays clear. It will not get scratched or rubbed off.

-

UV stability: The label keeps its color and shape even after sitting in the sun a long time. It does not crack or fade.

-

High-contrast print: You can read the label from far away. This helps with readability.

Essential Tools for Panel Labeling: Max Letetwin & Epson LabelWorks

Using the right tool is key when you do electrical work. A label maker is needed for labeling. A professional label maker helps you make the job easier. It gives you labels that last a long time and stay in place. You can use it at the work site. It makes labels, fast and simple. A good label maker helps you get work done in electrical work. It is a must-have when you want labels that are strong and ready for use.

Two top names in this area are the MAX Letetwin and Epson LabelWorks printers. The MAX Letetwin Wire Marking Machine is good if you need to mark wires and tubes. Epson LabelWorks printers can make many kinds of strong, adhesive labels. Both are easy to find in Canada from sellers like DuraFast Label Company.

Key Features of the MAX Letetwin LM-550A3BH Printer

The [MAX LETATWIN LM-550A3BH](https://www.durafastlabel.ca/max-letatwin-lm550a3bh-pc-tube-and-tape-printer-for-electrical-marking-lm99013/ "https://www.durafastlabel.ca/max-letatwin-lm550a3bh-pc-tube-and-tape-printer-for-electrical-marking-lm99013/") is a fast printer that you can carry with you. It uses thermal transfer to make labels. You can use it for control panel marking, wire numbering, and device labeling. This is a good labeling printer for electrical workers. It helps you keep wires clear and easy to read and panels simple to use. The printing works well on heat-shrink tubing. You can also use it to make durable polyester tape labels. These labels be great for marker strips and other needs.

One great thing about this device is that it can make half-cut parts. This helps speed up your work a lot. The device is built strong and it can stand up to hard use. The rubber keyboard can handle rough shocks. You can also use a battery to power it, so it is easy to take with you to work or any other place you go.

Key features include:

-

The high-speed thermal transfer printer is made to work fast.

-

The printer can print on heat-shrink tubes, PVC tubing, and polyester tapes without waiting.

-

You can pick half-cut or full-cut options, and that makes the printer easy to use.

-

With big memory in the printer, you have room to save all your job data even when you are moving.

-

The printer can be linked to your PC. You can use LETATWIN PC Editor software when you want better design choices.

Advantages of Epson LabelWorks LW-PX900 for Professionals

The Epson LabelWorks LW-PX900 is a good choice if you need a strong printer that can last a long time. This printer is used by many people, especially those who do a lot of electrical labeling. It stands out because it works well and does not break easily. The machine also comes with some new tools that help you finish your work faster. You need less tape to print, which saves money. With this, you can do your labeling jobs in less time and spend less on supplies.

It gives you fast and clear results, so you can print precise labels like QR codes and wire markers. You will have better detail than a lot of other models. The LW-PX900 comes with a strong case that meets MIL-SPEC drop rules. It is made to last on tough job sites.

Key advantages include:

-

Rugged Design: It is built to be strong. It meets MIL-STD-810G drop test rules. So, you can use it at work or at home. It will keep working if you drop it.

-

Lifetime Warranty: Epson gives you a lifetime warranty. This lets you feel peace of mind knowing your product is safe.

-

High Print Quality: The labels are easy to read. You get good readability every time you print.

-

Versatile Media: It prints on different tapes. You can use magnetic, fluorescent, or heat shrink tape.

-

Time-Saving Features: With auto-cut and pick-and-print, it saves you time. It helps you work faster and better.

Best Practices for Organizing and Labeling Circuit Directories

A circuit directory, also called a panel schedule, shows how the electrical system in your building works. The directory should be neat. Each part needs to be labeled in a clear way. This is one of the best practices when you take care of an electrical system. A directory takes out the guesswork. People can fix issues more quickly. Troubleshooting becomes much easier. It also helps anyone working on the panel to do their work safely and smartly.

An accurate labeling system starts when you list each circuit the correct way. After you find each one, you need to put the information in the directory. Make sure it is easy to read and very clear. Below, you see the steps you need to follow to find your circuits. You also learn which tools to use to build a directory that looks professional.

Step-by-Step Guide to Mapping and Identifying Circuits

Mapping your circuits should be the first step to get accurate labeling. The best way to do this is to have two people. One person stays at the electrical panel. The other person goes all around the building. They check outlets, lights, and appliances. When you turn breakers off and on and talk to each other, you will know which circuit controls what. This makes labeling each circuit easy and right.

If you work alone, you will see that a circuit breaker finder can be a big help. To use it, start by plugging the transmitter into an outlet. After that, take the receiver to the panel. Use it to scan each breaker. The receiver will beep or blink when it finds the corresponding breaker. With this tool, you can quickly find the right breaker. There is no need to guess.

Here’s a simple process to follow:

-

Begin with the big double-pole breakers. These give power to the large things in your place like your stove or air conditioner.

-

Go step by step around your home or place of work. Move from one room to the next.

-

Check every outlet, switch, and thing that is fixed into the wall in each space.

-

Write down everything you find next to the breaker number. Use a simple sheet for this part.

-

When you finish, use a label maker to make clear and lasting labels.

Using Templates, Sticker Packs, and Custom Printing Options

Yes, you can find printable templates for electrical panel labels that you can change to fit your needs. These templates make your circuit directory easy to read and look better. A lot of online sites have free circuit breaker label templates. You can change these to suit your own panel. Just write the details for each breaker, print the template out on sticker paper, and put the labels on the electric panel door.

Some people like to choose sticker packs which are already made. It is easy, and you do not have to make stickers on your own. But if you want your stickers to look good and be durable, custom printing is the best option. A printer like the Epson LabelWorks LW-PX900 lets you make your own strong, durable labels whenever you need them.

Here’s how these options can help:

-

Templates: The templates help you keep the directory for your panel clean and easy to read.

-

Sticker Packs: These packs give you a quick way to do labeling for house circuits. There are not many ways you can change how they look.

-

Custom Printing: With this option, you have full control over the words, size, and the material for labeling. It gives you a neat and strong result that looks good and lasts long.

-

Label Maker Apps: A label maker can work with your phone by using an app. This makes it easy for you to make and print labels for your directory with your mobile device.

Advanced Labeling Solutions: Half-Cut Round Tubing & Special Applications

There are now other ways to mark wires besides using sticky labels. A lot of people still use heat shrink tubing. But there are some new ways that make it easy to mark wires and get the job done faster. One of these tools is the MAX Letetwin printer. This printer has a special half-cut round tubing method. It's something that changes the way we do wire marking now.

This new technology helps people to work quicker on the job. It slices the tubing just enough, so you can take it apart and use it at once. There is no need for any other tools with this. This shows that new label printers are built to match what electrical pros need for their work.

Benefits of Half-Cut Round Tubing vs. Heat Shrink, Wrap-Around, and Sleeves

Round tubing for wire marking may not be as popular as heat shrink or wrap-around labels. But, with the MAX Letatwin's half-cut technology, you can do wire marking much quicker. This new feature boosts the speed and helps make things easier for you than older ways, which can be slow and take more time.

The main benefit is speed. With half-cut tubing, you do not have to use heaters because the material does not need to shrink. You will not need scissors to cut it, and you will not need a screwdriver to break apart the markers. You just print a strip of markers, pull apart the half-cut tubing by hand, and then slide it onto the wire. You get a good marker in less time. This way is faster and helps save some extra work for you.

Here’s a comparison of the benefits:

-

No Extra Tools: There is no need to use heat guns, scissors, or any other tool for this.

-

Increased Speed: You only need to pull apart the pre-cut tubes, then put them right where you want.

-

Ease of Use: It be simple to follow the steps. This lets people use less time and effort.

-

Clean Finish: You get a neat look with wire marker. It also be easy for all people to read.

-

Cost-Effective: You save time and work. So, for bigger jobs, you spend less money.

Maximizing Productivity with the MAX Letetwin for Wire and Panel Marking

For people who work in electrical trades, keeping the wires sorted and the panels labeled is really important. The MAX Letetwin helps you with this job. It is the best way to make sure all your work is neat. The machine is made to help you work better, even in tough places. You can use it to print on things like tubing and polyester tapes. The MAX Letetwin is a good choice if you need one machine that will do all of this.

No matter if you have to mark terminal blocks, tell which wire is which, or make panel lists, the Letetwin helps make your work easier. The speed, strength, and special features it gives, like half-cutting, help you finish the job sooner. With these things, it will be a good tool to get the most out of your work at any job site.

The Speed Difference: Grip Tube, Heat Shrink Tube, and Sleeves

The speed you use to mark items can affect how much you get done, especially when you work on big jobs. The type of marking material you use will change how fast you finish. Old ways, like heat shrink tubes, need you to do several steps. You have to cut the tubes, place them, and then heat them up.

The MAX Letetwin's Grip Tube and half-cut round tubing make things simple. You get these tubes already cut. You do not have to use heat to prepare them. This lets you finish your work faster. You will be able to get more markers ready in the time you once needed to prepare just a few heat shrink sleeves.

This table shows how the usual steps are not the same.

|

Marking Method |

Preparation Steps |

Application Method |

Overall Speed |

|---|---|---|---|

|

Grip/Round Tube (Half-Cut) |

Print and pull apart |

Slide onto wire by hand |

Very Fast |

|

Heat Shrink Tube |

Print, cut to size, position |

Slide onto wire, apply heat |

Slow |

|

Wrap-Around Label |

Print and peel |

Carefully wrap around wire |

Moderate |

|

Sleeve & Profile |

Print, cut, insert wire |

Thread wire through sleeve |

Moderate to Slow |

Choosing the Right MAX Letetwin Grip Tube for Your Needs

The MAX Letatwin has several types of grip tubes. Each one is made for a different wire size or need. You want to pick one that fits the wire well. That way, the tube will stay on the wire better. The grip tube is made to grab the wire by itself. It does not need glue or heat to stay in place. This helps your marking be clear and last a long time.

To pick the right tube, you need to know how wide the wire or cable is on the outside. The grip tubes come in many sizes. Each one is made to fit a certain width of wire. If the tube is too big, it may slide off the wire. But if the tube is too small, you will not get it on the wire.

Here are some easy tips that can help you choose the right grip tube.

-

Measure how wide your wire is from the outside.

-

Look at the MAX Letetwin chart. Use it to find the tube size that fits your wire width.

-

Think about where you will use this. Make sure the tube material is right for that place.

-

If you put wires together, choose a tube that is bigger. It should be able to fit all the wires inside.

-

You can ask for a sample pack. Try out many sizes with the wires you use most.

Specialized Applications: ID Plate Labeling and Tool Identification

Modern label printers do more than just mark wires and panels. You can use them to create durable ID plates for your equipment and tools. These plates help you know what is yours and keep things in order. This makes asset management easier and helps you organize everything better in your facility.

When labeling terminal blocks, control panels, or any pieces of equipment, you need to be sure the labels last. A printer such as the MAX Letetwin or Epson LabelWorks can help you with this. It is made for labeling and uses strong materials that stay good over time.

Creating Durable ID Plates for Panels and Terminal Blocks

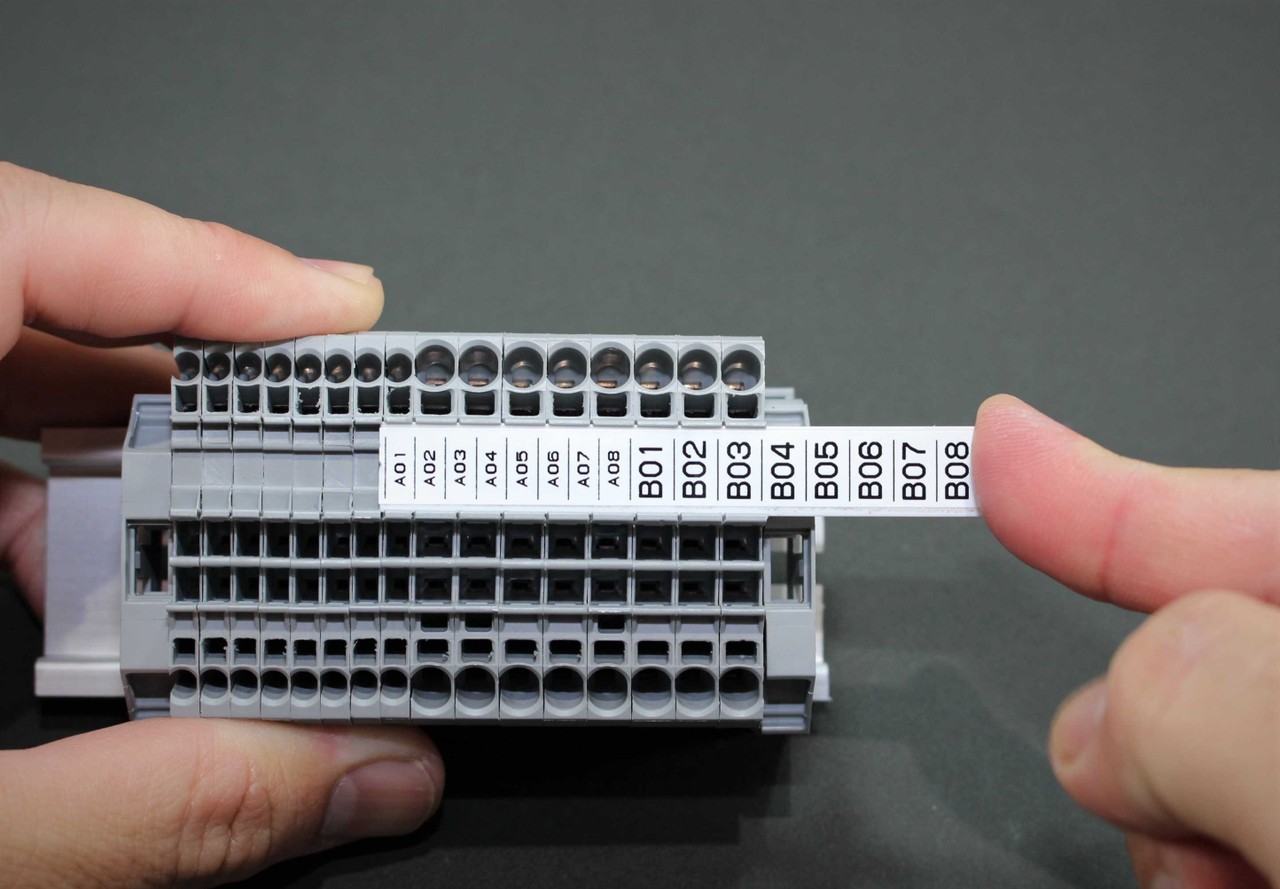

Making strong ID plates for electrical work is important. You need clear and durable labeling on electrical panels, switchboards, and also on terminal blocks. The MAX Letatwin does a good job with this. It prints on polyester tapes that last. You can use the tape on plastic holders to get hard and tough ID plates. This works well for labeling several terminal blocks or to show one is the main control panel.

This way lets you make marker strips that look good and are easy to read. They will last a lot longer than strips that you write on by hand. The text made with thermal transfer printing will not smear or fade. It will stay on the strip and not come off, even if the place is hard to work in. The marker strips are durable, and they will keep looking nice for a long time.

To create your own ID plates, you can:

-

Use the printer’s software or the device itself to make the label.

-

Print the label on strong and durable MAX polyester tape.

-

Put the tape on a blank ID plate or in a marker strip holder.

-

Snap the plate into place on the terminal block or stick it on the panel.

-

This will give all your equipment a clean and standard look.

Tips for Marking Electrical Tools and Equipment

Marking electrical tools and equipment helps you keep track of the items and stops people from losing things. A strong and clear label with your company name or asset ID number is a smart idea since it makes it easy for people to find items, even when you have a lot happening on the site. The Epson LabelWorks LW-PX900 label maker is good for this job. It comes with many types of industrial tapes, so you can make durable labels that last and work well.

When you label your tools, pick tape that will last a long time and not fall off. It is good if the tape can handle rough use. It should be strong, even with moisture or grease on it. A tough glue on the tape helps keep the label in place. You can use this tape for both plastic drills and metal toolboxes.

Here are some simple tips to help you spot tools more easily:

-

Use a strong industrial tape that sticks well.

-

Make sure to have your company name and phone number on the label.

-

Give each piece of equipment its own ID number. This can help you keep track of assets.

-

Place the label where it is easy to see. But pick the spot so it does not wear out from daily use.

-

You can also use a tape that shows if someone tries to take it off. This can make things safer.

Maintaining and Updating Your Electrical Panel Labels

Labeling your electrical panel is not something you only do one time. In a year, you should look at it and keep all the labels up to date. This is to help with both safety and the work of your electrical system. A label can stop sticking, come off, or be wrong if you add or change things in the electrical system.

It is important to take care of labeling in a proactive way. You need to check your labels often. Make sure people can read them. Fix any mistakes right away. If there has been electrical work, change the labels at once. A system with up-to-date and easy-to-read labeling shows the property is safe. It also shows the people taking care of it do a good job.

Inspection Checklist and Update Frequency

You need to check your electrical panel labels at least one time every year. It's also good to update these labels right after you make changes. For example, when you add a new circuit or set up a new appliance. This helps keep your directory up-to-date with the right details. It will help you and other people know what has changed or been added after modifications to the electrical panel.

A regular check can help you see problems with your electrical system before they get worse. A checklist makes sure you do not forget to look at anything important. It helps keep your electrical system safe and easy to use.

Here is a simple inspection checklist you can use:

-

Legibility: Are the labels clear to read? Can people see the words on each one?

-

Accuracy: Does every label show the right breaker or circuit it controls?

-

Adhesion: Are any labels peeling off, cracked, or not sticking well to the panel?

-

Completeness: Is there a label for every breaker, including all spares?

-

Directory Match: Is the panel directory the same as the labels on the breakers?

-

Recent Changes: If there was electrical work or renovations, has the labeling been updated?

Troubleshooting Common Labeling Issues

Even if you try to do your best with labeling, you may still face some problems later on. A lot of times, it is hard to read the labels or they have faded. Sometimes, the labels have wrong names for the circuits. There can be times when labels fall off because the sticky part does not work well, or the spot is rough on the labels.

Troubleshooting problems like these can be easy if you use the right tools and follow a clear plan to fix things. If the label has faded, you can just put on a new one. But this tells us why it is good to start with durable materials that last a long time.

Here are some common issues and how to solve them:

-

Faded or Illegible Labels: If you find the label is light or hard for people to read, swap it as soon as you can. A durable label that does not wear out in the sun is best. A good kind to use is industrial polyester.

-

Incorrect Information: When the label has wrong information, use a circuit finder to find the right details. Make a new label that is correct.

-

Peeling Labels: A label that is coming off needs attention. First, clean the spot well. Put on a new label with strong glue so it will stick and stay there.

-

Vague Descriptions: A label with a name like "Bedroom" is too general. Make it clearer, such as "Master Bedroom Outlets." This way, people know what it means and what it is for.

-

Missing Directory: If there is no directory or panel schedule, track where all the circuits go and make your own from the start. A clear directory is needed to help everyone find what they need fast.

Conclusion

To sum up, having clear and correct labels on the electrical panel is key. It keeps people safe, helps you follow best practices, and lets you get work done much faster. Using good labeling tools like the MAX Letetwin and Epson LabelWorks printers will solve most marking issues. With these, you make the process simple and get strong labels that do not fade easy. When you use best practices and special items like half-cut round tubing, the system looks good and each part is easy to find. Do not let poor labeling cause problems for people. Choose the right labeling solutions today! If you need help with your electrical panel, talk to our team for a free session. We can show you top products and guide you.

Frequently Asked Questions

Where can I buy electrical panel labels and printers in Canada?

You can get everything you need for electrical labeling in Canada from DuraFast Label Company. We carry printers like the MAX Letetwin and Epson LabelWorks. These work well for panel labeling and other labeling jobs. We also offer tough tapes, heat shrink tubes, and more. All our products are built strong. They help you with wire marking, panel labeling, and other types of labeling tasks.

How do I know if my panel labels meet Canadian safety standards?

To follow the rules, you need to make sure your labels match the Canadian Electrical (CE) Code. This means that every circuit must be marked in a clear way. Use durable materials for your labels, so they will last a long time. You should also check the best practices from NFPA and ANSI. This helps you put the labels in the right spot, and people will be able to read them. When you do these things, you can meet and even go beyond the safety rules.

How often should I update labels on control panels and circuit directories?

You need to change your labels right away after you make any changes to your electrical system. This helps keep electrical safety high. It is a good idea to look at the whole panel schedule every year. Check if it is right and trade out any tags that look faded or broken. This way, you keep your electrical system safe and up to date.

What is the best way to label my electrical panel?

The best way to label your electrical panel is to create clear, concise labels that identify each circuit's function. Use a label maker for uniformity and visibility, ensuring the font is large enough to read easily. Regularly update labels as modifications occur to maintain clarity and safety.