What Your WHMIS Supplier Label Must Include.

11th Jul 2025

Imagine this: you're on the warehouse floor, juggling multiple tasks, and someone hands you a container with a chemical you’ve never used before. No idea what it does, how dangerous it is, or what to do if it spills. That confusion? It’s not just frustrating—it’s dangerous.

This is exactly where Workplace Hazardous Materials Information System (WHMIS) supplier labels come into play.

In industries where hazardous materials are part of daily operations—whether it’s a manufacturing plant, a construction site, or even a school science lab—clear, quick-to-read safety information isn’t just helpful, it’s essential. WHMIS labels serve as the first alert system, giving workers immediate insight into what they’re dealing with and how to handle it safely.

In this blog, we’ll break down why these labels matter so much, what they’re required to include, and how they help prevent accidents before they happen. Whether you're new to WHMIS or just need a quick refresher, you’ll see how these little labels make a big impact on workplace safety.

What makes WHMIS Supplier labels non-negotiable in the workplace?

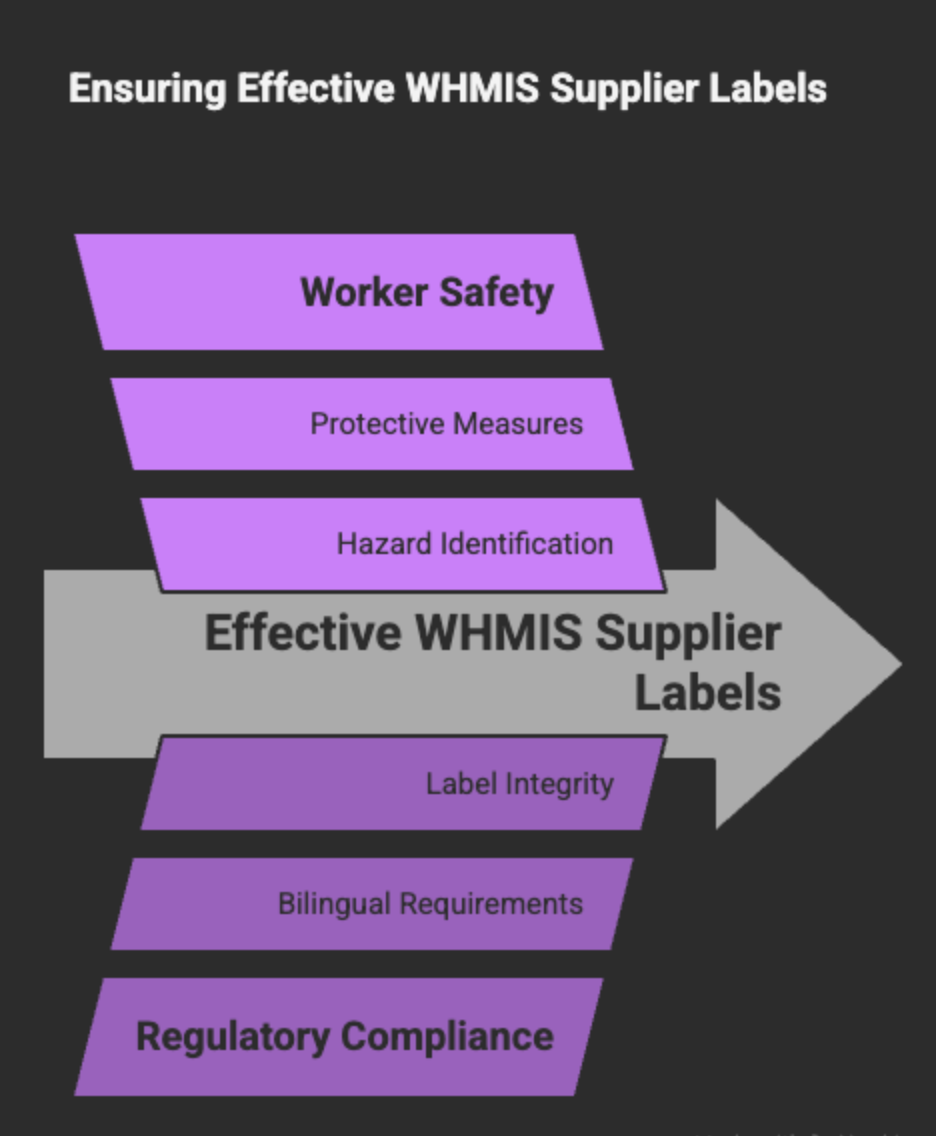

In numerous industries ranging from manufacturing and construction to healthcare, understanding the contents of a WHMIS supplier label is crucial for ensuring worker safety. Therefore, the most fundamental step in managing potential hazards at a workplace starts with a thorough understanding of WHMIS supplier labels.

1. Role in worker safety for the WHMIS workplace label

Supplier labels serve as an on-the-spot safety manual for any worker exposed to hazardous materials. They display the product name, its potential hazards, as well as safe handling precautions for appropriate handling methods, thereby acting as an immediate source of information and helping workers identify risks and take necessary protective measures.

A Safety Data Sheet (SDS) is vitally linked to supplier labels- while labels provide summary information, the SDS gives in-depth details about the hazards and safety measures associated with a given product. The availability of immediate summary and detailed hazard information makes WHMIS supplier labels indispensable tools for workplace safety.

2. Compliance with regulations for WHMIS product labels

For every workplace in Canada involving hazardous materials, compliance with WHMIS regulations concerning supplier labels and shipping papers is mandatory as per the Hazardous Products Act. These labels need to be bilingual and impart crucial hazard information such as hazard pictograms, signal words, and hazard/precautionary statements. If a supplier label is damaged, illegible, or missing, it must be replaced with a workplace label according to the regulations.

Failure to adhere to these labeling regulations can result in stringent fines and penalties, making appropriate WHMIS supplier labeling not just a safety necessity but also a significant legal requirement.

What key elements make a WHMIS Supplier label effective?

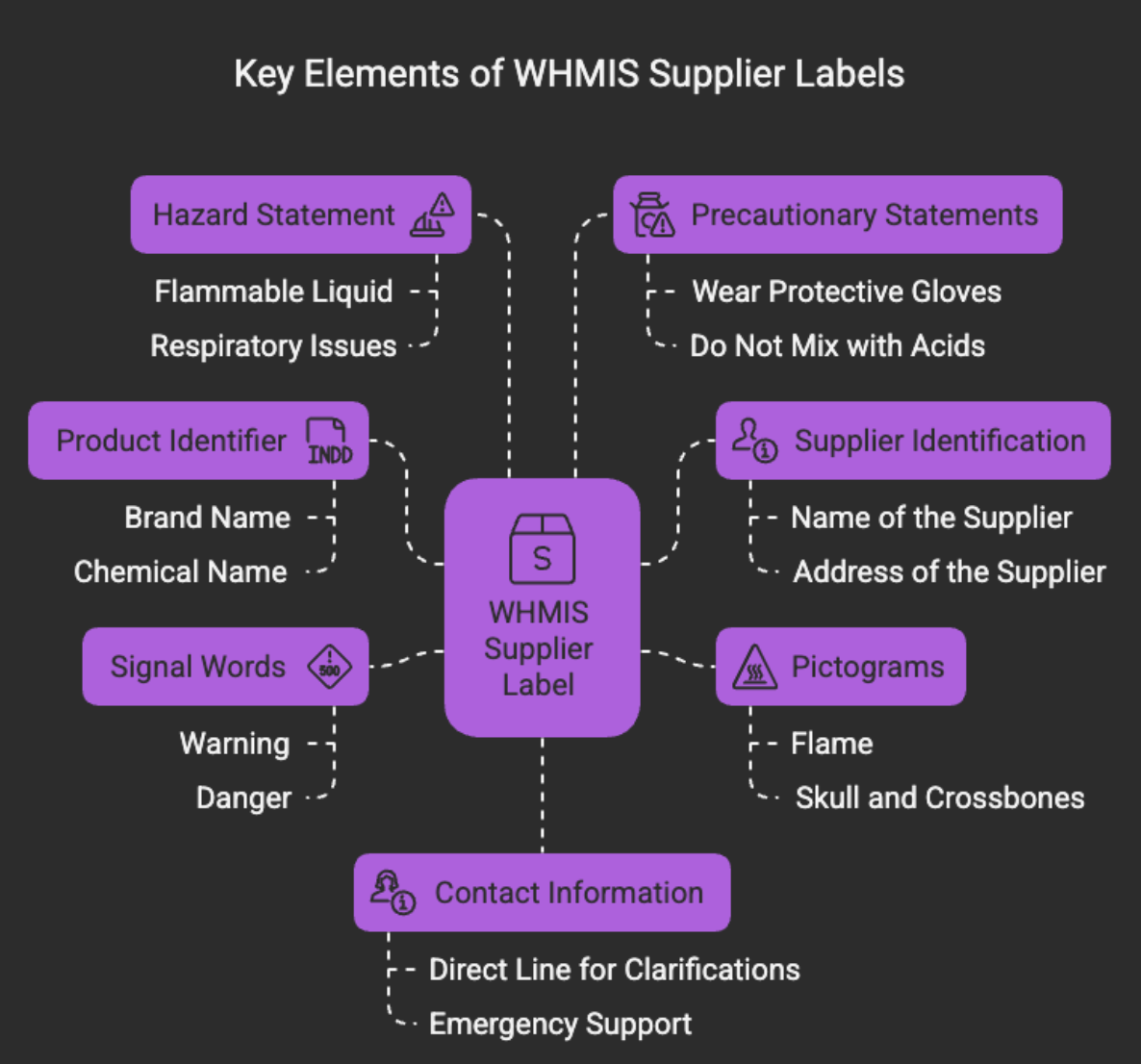

Every WHMIS supplier label is expected to contain several mandatory elements that impart critical information. In the following sections, we will delve into each of these elements more closely.

1. Product Identifier and Product Name

The product identifier forms the starting point of the supplier label. This typically includes the brand name, chemical name, common name, generic name, or trade name of the hazardous product. It serves as a standard reference across containers and Safety Data Sheets (SDS), enhancing the coherence of hazard communication.

|

Product Identifier |

Purpose |

|

Brand Name |

Identifies the brand under which the product is marketed |

|

Chemical Name |

Specifies the scientific name of the product |

|

Common Name |

Helps in the easy recognition of the product |

|

Generic Name |

Used when a specific brand/chemical name doesn't exist |

|

Trade Name |

Indicates the trading name under which the product is sold |

2. Supplier Identification

This section allows users to contact the supplier for additional information about the product, reporting issues, or seeking clarification regarding the product's handling.

-

Name of the Supplier: Identifies the Canadian manufacturer or importer responsible for the product.

-

Address of the Supplier: Provides a physical location for reference, accountability, or official correspondence.

-

Telephone Number: Offers a direct line for urgent questions, safety concerns, or emergency support.

-

Facilitates Communication: Enables quick contact with the supplier for clarifications on safe usage or product details.

-

Ensures Accountability: Holds the supplier responsible for the accuracy and reliability of the safety information provided.

3. Pictograms

Pictograms are symbols attached to a red-bordered diamond that represents a particular class of hazard, including a hazard symbol. These visual elements provide quick comprehension of the existing hazards like flammability, toxicity, or other characteristics. Here, we will discuss four primary pictograms:

-

Flame: Denotes that the substance is flammable, self-heating, emits flammable gas, or contains self-reactive or organic peroxides.

-

Health hazard: Indicates that the substance can cause health issues such as respiratory sensitization, mutagenicity, carcinogenicity, etc.

-

Skull and Crossbones: Warns of acute toxicity that can cause fatal or severe harm if inhaled, swallowed, or comes in skin contact.

-

Exclamation mark: Highlights health hazards such as skin or eye irritation, skin sensitization, or specific target organ toxicity.

4. Signal Words

Signal words serve to indicate the severity of the hazard class and quickly communicate the level of hazard severity associated with a the classification of the product..

-

Labels: The "Warning" label indicates less severe hazards, but still calls for careful handling. On the other hand, the "Danger" sign signifies more serious or immediate risks, requiring extra caution and attention.

-

Promotes Immediate Awareness: Helps users instantly assess the level of risk before using the product.

-

Encourages Safe Handling: Prepares users to take appropriate precautions based on the product’s danger level.

5. Hazard Statement

Hazard statements are brief standardized phrases encapsulating the nature of the hazards posed by a product, helping to convey the degree of the hazard. For instance, "flammable liquid" or "can cause respiratory issues," clearly highlight the main risks associated with the product, helping users understand the primary precautions necessary for safe usage to minimize or prevent adverse effects.

-

Standardized Language: Ensures consistency across products, making labels easier to understand at a glance.

-

Supports Safe Decision-Making: Enables users to take the right safety measures before using the product.

6. Precautionary Statements

Precautionary statements present directives to minimize detrimental effects from improper handling and exposure to the product. There are five types of precautionary statements. Examples of precautionary statements effectively guide workers to take safety measures with simple, practical steps that go a long way.

-

Supports Use of Personal Protective Equipment (PPE): Many statements will mention when to wear protective gear to minimize exposure risks. For example, you may find signs like "Wear protective gloves," "Keep away from heat," or "Use only in well-ventilated areas".

-

Helps Avoid Dangerous Reactions: Some products shouldn’t be mixed or stored near certain materials—precautionary statements will flag this, like "Do not mix with acids".

-

Emergency Response Tips: You’ll also find informaton like "In case of contact with skin, rinse immediately"—so you know exactly what to do if something goes wrong.

-

Promotes Safer Work Habits: When these directions are followed consistently, they create a culture of safety across the workplace.

7. Contact Information

The label also features supplier contact information, promoting a proactive approach to safety.

-

Direct Line for Clarifications: Workers can easily reach out to the supplier if they have questions about the product’s use or safety instructions.

-

Emergency Support: In case of a spill, exposure, or accident, having a contact number handy ensures fast access to expert guidance.

-

Reporting Issues: If there's a defect, mislabeled product, or unexpected reaction, the contact information lets users report problems directly to the source.

-

Promotes Accountability: Having clear supplier details encourages responsibility and transparency from manufacturers and importers.

-

Strengthens Safety Communication: Builds a stronger, proactive safety culture by keeping lines of communication open between the supplier and end users.

Supplementary Information on WHMIS Labels

Beyond these essential elements, suppliers can add supplementary information to the label regarding unknown toxicity. This additional data might include fire-fighting measures, first-aid measures, environmental precautions, physical state, route of exposure, etc. This ensures more comprehensive safety guidance is available at a glance, enhancing the effectiveness of these labels.

1. WHMIS product supplier labels have one or more emergency contact numbers

Emergency contact numbers are crucial in cases of accidental exposures or other emergencies. Workers can reach out to these contacts for immediate medical advice or specific information on handling the product in case of an accident. This information needs to be clearly visible on the label, boosting the prompt response in an emergency situation.

|

Supplier |

Emergency Contact Number |

|

Company A |

123-456-7890 |

|

Company B |

987-654-3210 |

|

Company C |

456-789-0123 |

2. Date of label preparation- the other thing the WHMIS supplier label must include

The date of label preparation indicates when the given information was last verified and updated. It is a crucial element, especially considering that suppliers are required to update labels with any significant new data within a specified time frame. This promotes transparency in hazard communication, keeping all users updated and aware.

What Label Printers Should You Invest in for Workplace Hazardous Materials Labels?

Proper labelling of hazardous materials is essential for safety compliance and workplace clarity. Whether you need full-colour GHS-compliant labels or single-colour safety signage, choosing the right printer ensures your labels are durable, legible, and regulation-ready. Below are the two main printer categories with recommended models for each.

Full-Colour Pigment Inkjet or Laser Label Printers

These printers are ideal for GHS-compliant labels that require full-colour hazard symbols, text, and graphics. They produce water-, smudge-, and chemical-resistant labels suitable for industrial use.

1. Afinia L502 Color Label Printer with Pigment Inks

Built for durability with dual-ink compatibility (dye & pigment), the Afinia L502 Color Label Printer with Pigment Inks is also ideal for chemical and industrial labelling with high-resolution print quality.

2. Primera LX910 Color Label Printer with Pigment Ink

The Primera LX910 Color Label Printer with Pigment Ink has a single, high-capacity cartridge and it prints vibrant, full-colour labels with water-resistant pigment inks and minimal maintenance.

3. Primera LX600 Color Label Printer with Pigment Ink

Compact and efficient, Primera LX600 Color Label Printer with Pigment Ink is great for small-scale hazardous material labels, offering fast print speeds and crisp colour output.

4. Primera LX610 Color Label Printer with Cutter and Pigment Ink

Primera LX610 Color Label Printer with Cutter and Pigment Ink combines pigment ink printing with built-in die-cutting, allowing you to create custom-shaped labels for unique containers and safety needs.

5. Primera LX4000 Color Label Printer with Pigment Inks

Designed for high-volume use with super high-capacity ink tanks, the Primera LX4000 Color Label Printer with Pigment Inks delivers reduced cost per label and excellent durability.

Laser Label Printer

Afinia LT5C Color Laser Label Printer

A laser-based solution for durable, UV- and chemical-resistant labels, the Afinia LT5C Color Laser Label Printer supports printing on specialty materials like PET and synthetic stocks.

Thermal Transfer Label Printers (Single-Colour Printing)

These are best for single-colour safety labels with clear text and symbols. Thermal transfer printers offer strong adhesion and long-lasting print on synthetic label materials.

1. Godex G530 – 4" Wide, 300 dpi Thermal Transfer Printer

Compact and reliable with high-resolution output, the Godex G530–4" Wide, 300 dpi Thermal Transfer Printer is ideal for barcode and hazard label printing on synthetic or glossy label stock.

2. Godex HD830i – 8.6" Wide, 300 dpi Thermal Transfer Printer

A wide-format industrial printer, the Godex HD830i – 8.6" Wide, 300 dpi Thermal Transfer Printer is designed for oversized safety labels and facility signage, offering precision and consistent performance.

3. Brother TD4750TNWBCS – 4" 300 dpi WiFi Label Printer with Cutter

High-speed, network-ready printer with built-in cutter, the Brother TD4750TNWBCS – 4" 300 dpi WiFi Label Printer with Cutter is perfect for producing durable, custom-length hazard and facility ID labels on demand.

Tip: Choose a pigment inkjet or laser printer for full-colour chemical labels and thermal transfer if your focus is high-volume, black-and-white safety signage.

Ready to Elevate Your Workplace Safety?

At DuraFast Label Company, we understand that when it comes to hazardous materials, clarity and reliability are non-negotiable. That's why our WHMIS supplier labels are crafted with precision and care, ensuring your team has the information they need to stay safe.

Why Choose DuraFast for Your WHMIS Labels?

-

Tailored for Your Printers: Our labels are specifically designed for seamless compatibility with leading colour label printers like Epson, Primera, and Afinia. This means you get crisp, clear prints every time, enhancing readability and compliance.

-

Durability You Can Trust: We know that labels need to withstand the rigors of your environment. That's why our labels are engineered to be durable and colourfast, ensuring they remain legible and intact, even in challenging conditions.

-

BS5609 Certified: For industries requiring the highest standards, our chemical labels are BS5609 certified. This certification guarantees that our labels can endure long-term immersion in saltwater and exposure to harsh chemicals without deteriorating.

-

Expert Guidance: Not sure which label solution fits your needs? Our team of consultants is here to help you select the perfect colour label printing system tailored to your specific requirements, ensuring you get the most out of your investment.

Don't settle for less when it comes to workplace safety. Partner with DuraFast Label Company today and experience the difference that quality, durability, and expert support can make.

Contact Us Today!

-

Website: www.durafastlabel.ca

-

Phone: 1-866-299-0066

Conclusion: Labels That Do More Than Stick

At the end of the day, WHMIS supplier labels aren’t just stickers on a bottle—they’re critical tools for keeping workplaces safe, informed, and compliant. Whether it’s a busy manufacturing floor filled with flammable chemicals or a healthcare facility stocked with powerful disinfectants, these labels act as a first line of defense, giving workers the info they need right when they need it.

By clearly communicating hazards, proper handling precautions, and emergency contact details, WHMIS labels take the guesswork out of safety. And when workers truly understand what those labels mean? That’s when the magic happens—accidents are reduced, response times improve, and everyone goes home safe.

So, whether you're labeling ethanol in a factory or bleach in a clinic, remember: a well-designed WHMIS supplier label isn’t just a regulatory checkbox—it’s a safety ally. Keep them clear. Keep them compliant. And most importantly, make sure your team knows how to read and use them.

Because in a world full of risks, knowledge isn’t just power—it’s protection.

Frequently asked questions

What must a WHMIS supplier label include legally?

Legally, a WHMIS supplier label must include the product identifier, supplier identification, different types of labels such as pictograms, signal words, hazard statements, precautionary statements, and first aid supplier contact information. Any significant changes in product information must be updated as per WHMIS regulations.

What are the 2 types of WHMIS labels?

The two types are Supplier Labels and Workplace Labels. Supplier labels come from the manufacturer, while workplace labels are created by the employer when needed.

What are the three things required on a workplace label?

A workplace label must include the Product name (matching the SDS), Safe handling instructions, and Reference to the Safety Data Sheet (SDS).

How often should WHMIS labels be updated or reviewed?

WHMIS labels should be updated as soon as any significant new data about the product’s hazards becomes available. Suppliers are legally required to update labels by December, within 180 days of becoming aware of such information.

Can digital labels be used as a substitute for physical WHMIS labels?

No, digital labels cannot replace physical WHMIS labels. The label must be affixed to, printed on, or attached to the product or its container and remain legible throughout its lifecycle.

What are common mistakes made when creating WHMIS labels?

Common errors include omitting important elements like pictograms or hazard statements, not updating information after gaining significant new data, producing labels that are not in English and French, or failing to replace damaged or illegible labels.

Are there specific guidelines for the label's size and font?

The WHMIS regulations don't specify a particular size or font for labels. However, they mandate that the label information must be easy to read and prominently displayed on the product under normal use of the product transportation.

What role does WHMIS training play in understanding these labels?

WHMIS training enables workers to understand and interpret supplier labels effectively. It equips them with the knowledge to decode different label elements, helping to implement correct safety measures and handle hazardous substances responsibly.