Tips for Storing and Handling Blank Labels Correctly

5th Dec 2025

Most businesses focus heavily on printer quality, ink types, and label design — but very few consider how storage affects the final result. Blank labels, especially inkjet labels, are sensitive materials that respond to temperature, humidity, and handling. Even the slightest mismanagement can lead to curling, fading, or adhesion failure during printing or application.

At DuraFast Label Company, we’ve seen firsthand how proper label storage and care can mean the difference between a flawless print run and wasted materials. Labels are an investment — and like any consumable, they must be stored with care to maintain consistency, color fidelity, and adhesive performance.

This guide walks you through the most effective ways to store, handle, and protect your labels so they perform perfectly every time you print.

Understanding Label Composition and Sensitivity

Every label is made from multiple layers — the facestock, adhesive, and liner — all of which can be affected by environmental conditions.

The facestock determines how the ink adheres; the adhesive determines how well the label sticks; and the liner ensures smooth feeding through your printer. If any one of these layers degrades, print quality and application suffer.

For example, inkjet labels have coatings designed to absorb dye or pigment ink quickly. If they’re exposed to humidity, those coatings absorb moisture and lose precision, causing smearing and color bleeding.

Proper storage preserves the integrity of all three layers and ensures the labels feed cleanly through your printer, avoiding costly reprints or downtime.

Ideal Environmental Conditions for Label Storage

Temperature Control

Blank labels should always be stored in a stable, climate-controlled environment. Extreme heat can dry out adhesives, while cold or damp spaces can cause labels to absorb moisture.

For most label materials, a temperature range between 18 °C and 24 °C (65 °F to 75 °F) works best. Avoid storing labels near heaters, windows, or cooling vents that create uneven conditions.

Humidity Levels

Humidity control is just as crucial. Labels stored in high humidity may warp or curl, leading to misfeeds during printing. Conversely, very low humidity can make the liner brittle.

Maintain relative humidity between 40 % and 60 % for consistent performance. If you operate in a region with extreme climate variations, consider dehumidifiers or sealed containers to stabilize the environment.

Avoid Direct Sunlight

Ultraviolet light accelerates ink and material degradation. Even unused rolls can discolor or dry out if left exposed. Always store labels in their original packaging or opaque boxes.

Handling Labels the Right Way

Minimize Physical Contact

Finger oils, dust, and micro-abrasions can all compromise label surfaces. When handling label rolls or sheets, hold them by the edges and avoid touching the printable face.

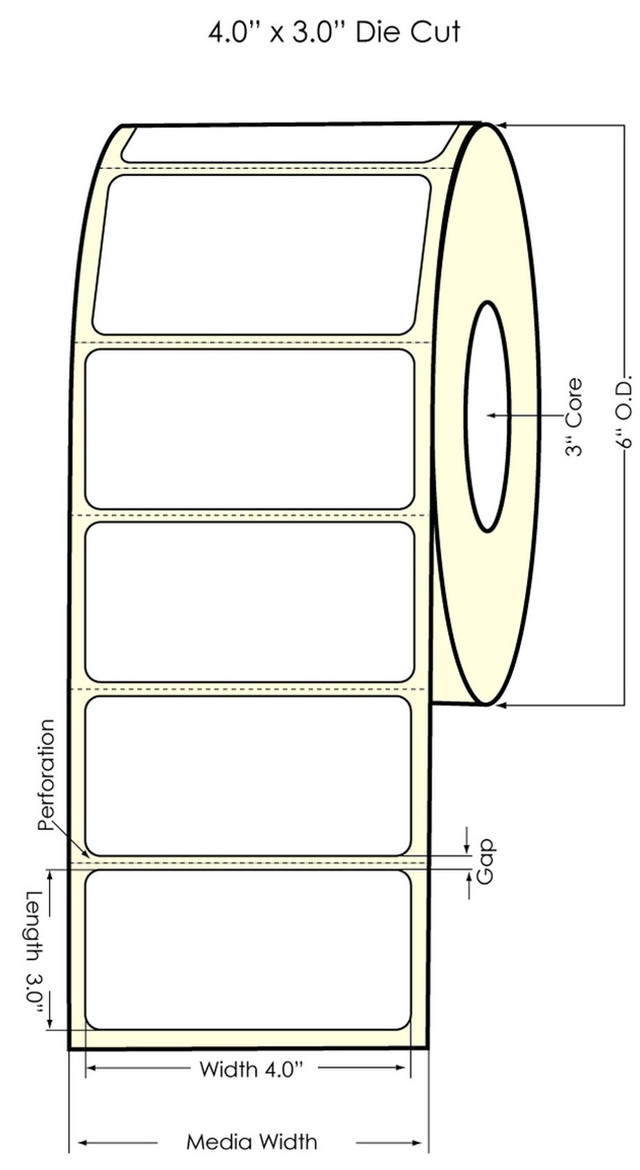

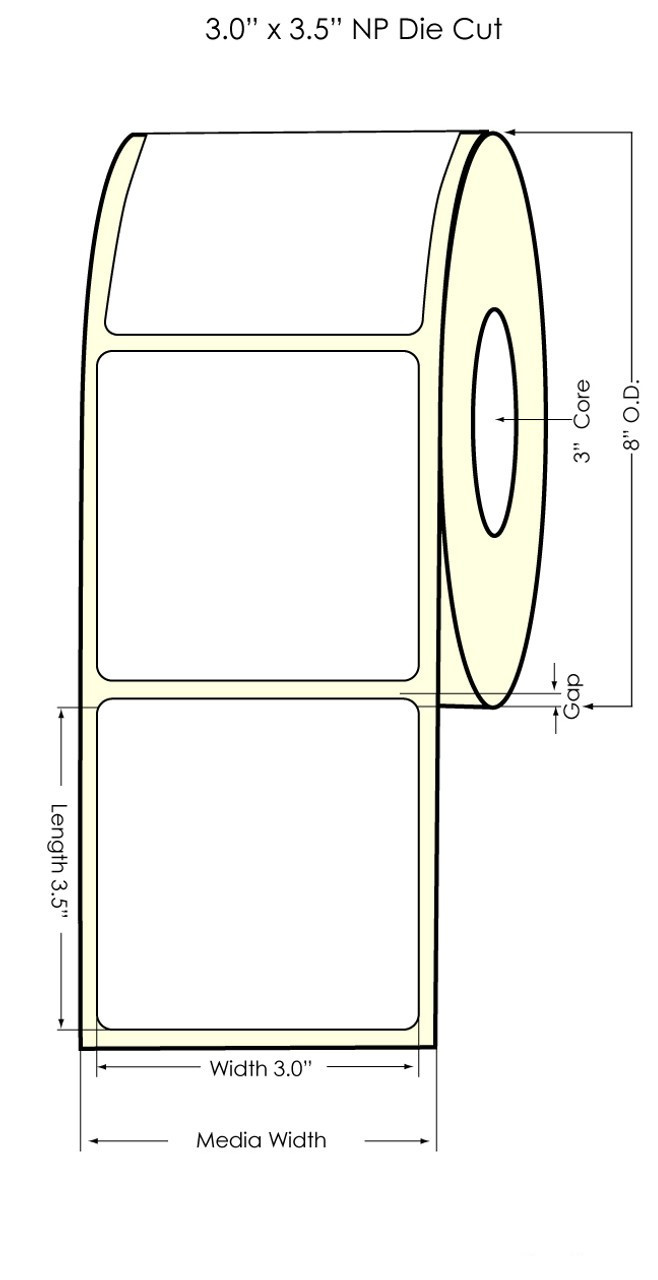

For example, if you’re working with VIPColor VP485 Inkjet Labels, such as the 3 × 3.5 Glossy Polypropylene Labels, smudges or fingerprints can cause uneven ink absorption, resulting in dull patches after printing.

Keep Labels Clean

Dust buildup can cause print defects and feeding errors. Regularly clean your storage shelves and ensure labels remain sealed in plastic wrap until ready for use.

At DuraFast, we recommend storing partially used rolls in resealable bags with silica gel packs to prevent moisture absorption between uses.

Roll Orientation

Always store rolls horizontally on their sides rather than standing upright. This prevents flattening or “out-of-round” deformation that leads to printer jams.

When storing sheets, keep them flat — stacking them too high or bending corners can cause the edges to lift and create feed errors later.

Shelf Life and Expiry of Blank Labels

Labels are perishable goods in their own way. Adhesive and liner materials have a limited lifespan, usually between 12 and 24 months, depending on the type.

Over time, adhesives may lose tackiness, facestocks may become brittle, and liners can start releasing too easily. Even premium products like VIPColor VP485 4 × 3 Holographic Film Labels benefit from routine inventory rotation.

To avoid waste, follow the “first in, first out” rule — always use your oldest label stock before newer shipments.

Packaging and Protection During Storage

Labels should remain in their original packaging whenever possible. Manufacturers design packaging to protect from dust, light, and temperature fluctuations.

For extra protection in industrial environments, consider sealed bins or vacuum-wrapped storage. Keeping labels in dark, dry cabinets ensures that even sensitive adhesive layers remain stable.

All inkjet labels that DuraFast Label Company sells are always enclosed in a poly bag or shrinkwrap to protect the inkjet topcoated. Always store the labels in a poly bag and carton to minimize exposure to heat and humidity. This will prolong the label life and improve the printed quality of the label designs printed.

Printer Preparation: Adapting Labels to Room Conditions

Before loading labels into your printer, let them acclimate to room temperature for at least 24 hours. This is especially important if labels were stored in colder environments or transported from a warehouse.

Skipping this step can result in curling or condensation on the label surface — both of which affect printhead contact.

At DuraFast Label Company, we advise clients to store labels near the printer area once opened to maintain consistent conditions between storage and printing.

Avoiding Common Storage Mistakes

Improper storage is one of the most frequent causes of print inconsistencies. Let’s look at a few common errors and how to prevent them:

1. Leaving Rolls Partially Unwrapped

Once exposed to air, label rolls begin to absorb ambient humidity. Always rewrap rolls tightly after use to prevent curling or adhesive transfer.

2. Storing Near Machinery

Printers, laminators, or packaging machines generate heat and vibration. These forces can warp label rolls and cause adhesives to soften prematurely. Keep storage areas separate from production floors whenever possible.

3. Ignoring Adhesive Compatibility

Different adhesives behave differently under humidity and heat. Permanent adhesives require stable temperatures to maintain viscosity, while removable ones may dry faster.

If your business uses VisitorPass Inkjet Name Badges on sheets, like the 3 × 2 Full-Expiring Inkjet Badges, ensure they’re kept flat and cool to preserve their special chemical-reactive coating.

4. Overexposure to Fluorescent Lighting

Even artificial lighting emits UV rays over time. Labels stored in transparent bins near bright lights will degrade. Opt for opaque or UV-resistant storage containers.

Label Storage for Different Printing Technologies

Not all label types require identical care. Here’s how to adapt your storage depending on your printing technology.

Inkjet Labels

These labels have porous coatings that absorb ink precisely. Excess moisture causes premature ink absorption and bleeding. Keep them sealed and acclimated before use.

Thermal Transfer Labels

While more resistant to humidity, they’re sensitive to heat. Store them below 25 °C and away from direct sunlight to maintain adhesive tack and liner stability.

Laser Labels

Static electricity and humidity imbalance can cause laser sheets to stick together or misfeed. Maintaining moderate humidity prevents multi-sheet feeding.

Direct Thermal Labels

Direct thermal labels are especially sensitive to heat, light, and friction because they use heat-reactive coatings instead of ribbons or ink. Exposure to high temperatures, UV light, or pressure can cause the material to darken prematurely and reduce print clarity. Store these labels in a cool, dark environment—ideally below 25 °C—and keep them sealed until use to protect the coating and ensure long-term image stability.

At DuraFast, we carry all three types — from inkjet to thermal — and help customers choose the correct label composition for their environment and storage capabilities.

Handling Large-Scale Label Inventories

For larger facilities managing thousands of rolls, organization and documentation are key.

Implement a simple tracking system that records each lot’s arrival date, type, and storage conditions. This helps identify older batches before they expire.

Label storage racks should have good airflow and be kept off the floor to prevent moisture transfer. Avoid stacking rolls too high, as compression can cause core deformation.

If you store different label types — such as glossy polypropylene and matte paper — separate them to prevent chemical transfer between coatings and liners.

How Storage Conditions Affect Print Results

Small storage lapses often appear later as print problems.

Labels exposed to high humidity might feed unevenly, leading to image distortion. Overheated adhesives can ooze, leaving sticky residue on printheads. Even dust particles can cause missing print lines.

By contrast, labels stored under controlled conditions always print cleaner and apply more smoothly. Their colors remain vibrant, adhesives consistent, and liners stable — a direct reflection of quality control throughout your operation.

Testing and Quality Checks Before Use

Before large print runs, always test a few labels. Print a sample to check color accuracy, adhesion, and feed alignment.

This proactive step identifies potential storage-related issues early, saving time and waste. DuraFast clients often establish “test print” protocols for every batch pulled from long-term storage, ensuring flawless output.

The Environmental Impact of Proper Label Care

Efficient label storage isn’t just about performance — it’s also about sustainability. Poorly stored labels often end up discarded, increasing material waste.

By maintaining proper conditions and minimizing spoilage, your business reduces its environmental footprint while saving money. At DuraFast, we emphasize sustainability through both product design and usage practices — helping clients print smarter and waste less.

Building a Label Storage Routine

Optimizing label storage doesn’t require expensive equipment — just consistency.

Establish a routine that includes:

- Weekly checks of humidity and temperature.

- Monthly cleaning of storage areas.

- Rotation of stock based on purchase date.

- Regular review of printer calibration and media compatibility.

This habit-based approach ensures long-term efficiency and predictable print quality.

Bringing It All Together

When labels are properly stored, every aspect of production benefits. Printing becomes smoother, labels feed flawlessly, and end products look professional and consistent.

Neglecting storage, however, results in waste, delays, and frustration — all avoidable with a few best practices.

At DuraFast Label Company, we’ve built our expertise around helping businesses in Canada prevent such issues through education, quality materials, and superior customer support. Whether you use glossy polypropylene rolls, holographic films, or specialized name badges, we supply products that maintain their integrity through months or even years of storage.

Preserve Performance with DuraFast Label Company

Your labels are the foundation of your packaging and branding. Protecting them ensures every print reflects the quality your customers expect.

Explore some of our top-performing blank label options designed for longevity:

- Epson TM-C3500 labels

- Epson CW-C6500 Inkjet Labels

- Primera LX900, LX910, LX2000, LX3000 and LX4000 inkjet labels

- Afinia L701, L801, L901 Inkjet labels

We’re here to help you choose the right material for your workflow and guide you on how to store it for consistent, professional results.

To learn more or discuss your label management setup, contact DuraFast Label Company — and let us help you maintain quality from the warehouse to the printer.