Top Tips for Maintaining Your Thermal Label Printer

3rd Nov 2025

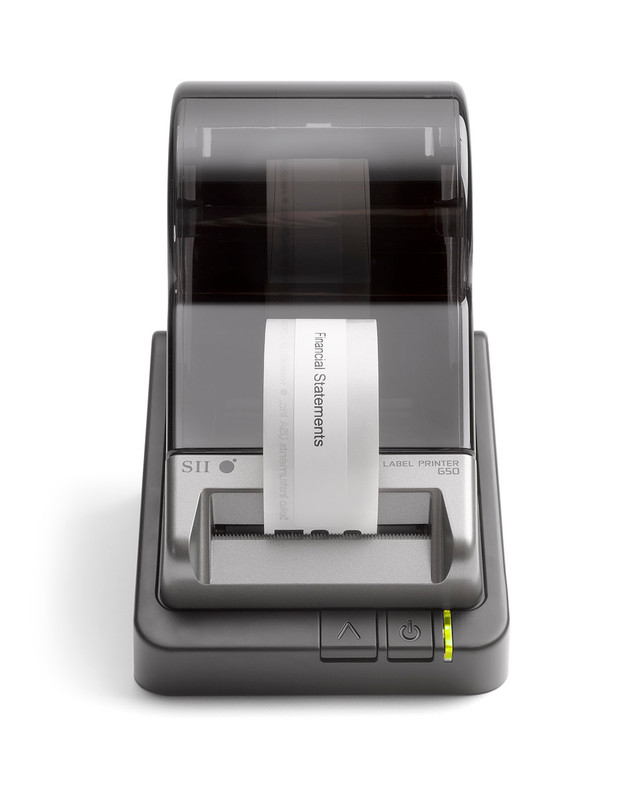

A high-quality thermal label printer is one of the most dependable tools in any modern business. From shipping labels and retail barcodes to warehouse tags and product packaging, these devices handle daily workloads with speed and accuracy. However, consistent performance depends on proper upkeep. Just like any piece of precision equipment, a thermal printer requires periodic maintenance to ensure consistent print quality, minimize downtime, and prevent costly repairs.

Many users assume that thermal printers are low-maintenance, because they do not use ink or toner. While that’s partially true, these devices still accumulate dust, residue, and wear over time. Understanding how to clean, calibrate, and maintain your printer can dramatically extend its lifespan and protect your investment.

Clean the Printhead Regularly

The printhead is the most important—and most delicate—component of a thermal label printer. It directly transfers heat to the label material, forming crisp images and barcodes. Over time, residue from labels, adhesive, and airborne dust can collect on the printhead, leading to faded or inconsistent prints.

For the best results, users should clean the printhead every time a new roll of labels or ribbon is installed. Cleaning pens or swabs designed specifically for thermal printers are ideal for this task. Avoid using sharp tools or household cleaners, as they can damage the thermal elements. Gently wipe in one direction to remove any buildup, and allow the printhead to dry before printing resumes.

Consistent cleaning not only improves output quality but also prevents overheating and premature wear, ensuring that your high-quality thermal label printers continue to perform reliably over time.

Use the Right Labels and Ribbons

The quality of the consumables directly affects printer performance. Using substandard or incompatible labels can cause jams, residue buildup, and uneven printing. It is best to select materials that are tested and recommended for your printer model.

For thermal transfer printers, pairing ribbons with compatible media ensures optimal heat transfer and clarity. Similarly, direct thermal printers perform best with high-quality heat-sensitive paper. Businesses sourcing thermal transfer labels or direct thermal labels for sale should confirm that these materials are rated for their specific printer and application environment.

Low-quality labels often contain excess adhesive, which can gum up rollers and cause feed issues. Investing in reliable supplies pays off through fewer maintenance issues and higher productivity.

Keep Rollers and Sensors Clean

Rollers guide labels smoothly through the printer, maintaining consistent alignment and pressure. When dust or label adhesive accumulates on these components, labels can skew, wrinkle, or jam. This not only affects print quality but also strains the printer’s internal mechanisms.

To clean rollers, use a lint-free cloth slightly dampened with isopropyl alcohol. Rotate the rollers manually to ensure even cleaning. Similarly, the sensors that detect label positioning should be inspected for dust or debris. Clean sensors carefully using a dry swab or air blower to avoid scratching the delicate surface.

Routine cleaning of rollers and sensors ensures labels feed correctly, reducing downtime and wasted materials.

Calibrate the Printer Periodically

Calibration ensures that the printer correctly detects label sizes, gaps, and sensor positions. If calibration is off, the printer may print over label edges or leave inconsistent spacing between labels.

Most modern printers include built-in calibration functions accessible via the control panel or software interface. Running calibration after every label change or at regular intervals helps maintain accuracy.

Using smart software such as Bartender label software or Nicelabel software also improves setup efficiency by allowing users to manage label templates, printer settings, and barcode accuracy from a centralized interface. This integration streamlines operations, especially when multiple printers are used across departments.

Maintain Proper Storage Conditions

Environmental conditions have a major impact on both printer performance and media quality. High humidity can cause labels to curl or jam, while excessive heat can affect the thermal coating, leading to faded prints.

Printers should be kept in a clean, dry environment away from direct sunlight or extreme temperatures. Label rolls and ribbons should also be stored in their original packaging until use to prevent exposure to dust and moisture.

Ensuring a stable environment not only extends the lifespan of the printer but also helps maintain the integrity of label materials like weatherproof labels and custom thermal transfer labels, which are often used in harsh or outdoor conditions.

Inspect and Replace Worn Parts

Even the best-maintained printers experience normal wear over time. Components such as rollers, cutters, and printheads have finite lifespans, and should be inspected periodically. Many manufacturers provide usage counters or alerts indicating when parts are nearing replacement.

Replacing parts promptly prevents more serious damage and ensures consistent printing quality. Keeping spare parts, such as Zebra ribbons or Intermec thermal ribbons, on hand minimizes downtime when replacements are needed. Additionally, maintaining an inventory of compatible supplies ensures quick maintenance cycles and prevents workflow interruptions. Regularly checking for firmware updates and following the manufacturer’s replacement schedule also helps optimize performance and extend the overall lifespan of the equipment, protecting the investment made in high-quality label printing.

Update Firmware and Drivers

Software updates may not seem directly related to hardware performance, but they play a vital role in maintaining compatibility and efficiency. Manufacturers frequently release updates that optimize print quality, improve connectivity, and fix bugs.

Ensure that your printer’s firmware and driver software are kept up to date. Updated software allows seamless integration with new operating systems and print management tools, reducing potential communication issues.

Businesses using multiple devices can benefit from centralized software management systems that automatically handle updates and calibration settings for high-quality thermal label printers.

Avoid Overheating During Heavy Use

Continuous, high-volume printing sessions can cause printheads to overheat, especially in direct thermal models. Overheating leads to uneven printing or premature wear on the printhead.

To prevent this, schedule printing tasks in manageable batches. Allow the printer a few minutes of rest after long runs to cool down. Monitoring print density settings can also help control heat output—lowering density slightly often prevents wear without affecting barcode readability.

If heavy-duty printing is a daily requirement, consider using thermal label printers with industrial-grade build quality to handle extended workloads efficiently.

Perform Regular Test Prints

Running a test print periodically helps identify early signs of wear or calibration issues. Test labels can reveal streaks, faded areas, or alignment errors before they escalate into larger problems.

Most printers include a self-test function that prints diagnostic patterns. Reviewing these test labels provides valuable insight into printhead condition, ribbon alignment, and general performance.

By scheduling routine test prints, users can catch minor issues before they affect large print runs, maintaining consistency across all outputs.

Train Staff on Proper Handling

In workplaces where multiple employees use label printers, inconsistent handling often leads to premature wear. Training staff on proper loading techniques, cleaning routines, and safe operation ensures the printer remains in top condition. Operators should understand how to replace ribbons, adjust feed paths, and handle label rolls correctly. Simple awareness of best practices can prevent common issues like label misalignment or residue buildup. Establishing a maintenance schedule and assigning responsibility for regular cleaning ensures accountability and prolongs equipment life.

In addition, creating quick-reference guides near each printer helps reinforce these habits and reduces user errors during busy work hours. Regular team refreshers or brief training sessions can keep everyone aligned on maintenance standards. Encouraging consistent care not only extends the lifespan of the equipment but also enhances productivity and ensures high-quality thermal label printers continue to produce precise, professional-grade results with every print run.

Extend the Life of Your Printer with Consistent Care

A well-maintained thermal printer can deliver years of flawless performance. From cleaning and calibration to software updates and responsible handling, each maintenance step contributes to consistent output and lower long-term costs. Regular care ensures clear, professional labels that uphold brand standards and operational efficiency.

For businesses in Canada ready to invest in durability and precision, high-quality thermal label printers and custom thermal transfer labels offer exceptional reliability for daily operations.

For those seeking dependable supplies and advanced solutions that enhance productivity, DuraFast Label Company provides professional-grade products and accessories in Canada designed to support every labelling need. Contact us today.