Thermal Transfer Labels: Understanding Materials, Ribbons, and Durability

18th Dec 2025

When it comes to creating labels that need to withstand time, handling, and environmental stress, thermal transfer printing stands out as one of the most reliable technologies in the world of professional labeling. It’s the method of choice for manufacturers, logistics companies, and laboratories that need clear, smudge-resistant prints that stay legible for years.

Unlike other printing techniques, thermal transfer technology offers exceptional longevity and adaptability. Whether you’re printing compliance barcodes, product identifiers, or asset tags, these labels are engineered to last under pressure — resisting abrasion, UV exposure, and temperature fluctuations.

At DuraFast Label Company, we’ve seen first-hand how businesses benefit from investing in durable, high-performance labeling systems. Thermal transfer printing isn’t just about appearance; it’s about performance. With the right combination of ribbon, label material, and printer settings, your labels won’t just communicate information — they’ll maintain their integrity through the full product lifecycle.

Throughout this guide, we’ll explore how thermal transfer labels work, the different ribbon types (wax, resin, and hybrid), and which materials will best suit your applications. You’ll also learn how to choose combinations that ensure the perfect balance between cost, quality, and durability.

If you’re considering upgrading your labeling process, there’s no better time to explore the benefits of thermal transfer labels that deliver premium, lasting results.

What Are Thermal Transfer Labels?

Thermal transfer printing is a specialized process that uses heat to transfer ink from a ribbon onto a label surface. Unlike direct thermal printing — which relies on chemically treated paper — thermal transfer technology uses a separate ribbon as an intermediary, producing sharp, stable, and long-lasting images.

This extra step makes all the difference. The result is a label that resists fading, smudging, and degradation from moisture or sunlight. That’s why thermal transfer labels are found everywhere from warehouses and factories to outdoor equipment and chemical drums.

Let’s break down how the process works.

How Thermal Transfer Printing Works

In a thermal transfer printer, a thin ribbon coated with ink (wax, resin, or a combination of both) passes between the printhead and the label material. When the printhead heats up, it melts the ink on the ribbon, transferring it precisely onto the label surface.

Each dot of heat represents part of a character, barcode, or graphic. Because the heat application is so controlled, the results are crisp and consistent — even at small font sizes or dense barcode resolutions.

The quality of a thermal transfer label depends on three key elements:

- The printer (responsible for applying heat accurately).

- The ribbon (which carries the ink).

- The label substrate (which receives the image).

When these components are properly matched, the printed image fuses with the label surface, becoming virtually permanent.

For example, businesses that demand reliability often turn to industrial-grade printers like the GoDEX G530 4" Thermal Transfer Barcode Printer. It’s engineered to handle large print volumes with precise temperature control — ensuring excellent results across wax, resin, and hybrid ribbon types.

The advantage here is not just print quality but consistency. Once your printer is properly calibrated, every single label looks identical, no matter the batch size.

Thermal Transfer vs. Direct Thermal Printing

One of the most common points of confusion in label printing is the difference between thermal transfer and direct thermal methods. Both rely on heat, but they produce labels with very different properties.

Direct Thermal Printing

Direct thermal printers use chemically treated paper that reacts to heat, forming an image without ribbons or inks. This method is fast, convenient, and cost-effective for short-term labeling needs like receipts or shipping labels.

However, because the image is created through a chemical reaction, it remains heat-sensitive — meaning it can darken, fade, or degrade when exposed to sunlight or friction. Direct thermal labels typically last between 6 months to 1 year, depending on storage and handling conditions.

Thermal Transfer Printing

Thermal transfer printing, on the other hand, uses a ribbon to transfer durable ink onto a separate substrate. This creates a far more robust print, capable of withstanding extreme temperatures, UV light, water, and chemicals.

This makes thermal transfer labels ideal for:

- Long-term product identification

- Industrial and chemical labeling

- Outdoor signage and asset tracking

- Laboratory and medical labeling

The difference in cost between the two technologies is quickly offset by thermal transfer’s durability and reduced need for reprints.

A great example of a dependable model for smaller operations is the GoDEX G330 4" Thermal Transfer Printer. It offers compact, high-clarity output perfect for moderate production needs, making it an accessible choice for businesses upgrading from direct thermal systems.

Advantages of Thermal Transfer Labels

- Durability: Ink is fused into the material, making it resistant to fading, scratching, and smudging.

- Versatility: Works with a wide range of materials — paper, polyester, polypropylene, and vinyl.

- Longevity: Suitable for both indoor and outdoor use, even in harsh environments.

- Clarity: Crisp barcodes and fine text remain legible under scanning equipment.

- Chemical and Heat Resistance: Perfect for products that undergo friction, cleaning, or sterilization.

Because thermal transfer labels maintain their integrity over time, they’re indispensable in industries like manufacturing, logistics, automotive, and healthcare — where reliable labeling is not optional but mandatory.

Common Uses Across Industries

- Warehousing and Logistics: For pallet, bin, and rack labeling.

- Retail: For high-volume barcode labeling and price tags.

- Pharmaceutical and Laboratory: For labeling vials and medical instruments requiring sterilization.

- Automotive and Industrial: For components exposed to heat, grease, or solvents.

- Food and Beverage: For durable date and ingredient labeling.

Each application comes with its own environmental challenges, which means the right ribbon and material combination is crucial — a topic we’ll explore next.

Why Matching Ribbons and Materials Matters

Not all thermal transfer ribbons are created equal. Choosing the wrong type can reduce legibility, durability, or even damage the printhead. The key is compatibility — matching the ribbon’s ink type with the label’s coating and material surface.

For instance:

- Wax ribbons work best on paper labels.

- Resin ribbons are ideal for synthetics like polyester.

- Wax/resin blends provide a balance of cost and resistance.

This careful pairing determines the ultimate durability of your printed labels, which is why experienced suppliers like DuraFast Label Company provide expert recommendations based on your industry and environment.

Types of Thermal Transfer Ribbons

Thermal transfer ribbons are at the heart of the printing process — the ink source that makes durable labeling possible. Choosing the right ribbon type affects not just the quality of your prints but also their resistance to smudging, scratching, and environmental damage.

Broadly, there are three types of ribbons: wax, wax/resin, and resin. Each serves a distinct purpose, depending on your label material and the conditions under which it will be used.

Wax Ribbons: Affordable and Reliable for Everyday Labeling

Wax ribbons are the most widely used and cost-effective ribbon type for thermal transfer printing. They contain a high proportion of wax-based ink, which melts at a relatively low temperature, making them ideal for high-speed printing on paper labels.

Wax ribbons are excellent for:

- Shipping labels

- Retail price tags

- Inventory tracking

- Office organization

However, while wax ribbons offer good print quality, they’re not as durable as resin-based options. The printed image can smear or fade if exposed to friction, chemicals, or moisture — making them best suited for indoor or short-term labeling.

A great example of a reliable, affordable printer for wax ribbon printing is the GoDEX G330 4” Thermal Transfer Printer. It delivers sharp, consistent output ideal for light industrial or retail environments that require quick turnaround times without sacrificing clarity.

Pro Tip: When using wax ribbons, pair them with uncoated or matte paper labels for the best adhesion and print sharpness.

For businesses that print in high volumes but don’t require extreme resistance, wax ribbons provide the perfect balance between affordability and legibility.

Wax/Resin Ribbons: The Best of Both Worlds

Wax/resin ribbons offer a versatile middle ground between the softness of wax and the hardness of resin. These hybrid ribbons combine the print smoothness of wax with the enhanced durability of resin, resulting in excellent resistance to smudging, moderate moisture, and handling.

They’re compatible with both paper and synthetic label materials and are particularly useful when you need long-lasting labels without the full cost of resin ribbons.

Typical applications include:

- Product identification labels

- Retail shelf tags

- Outdoor storage labeling

- Healthcare and logistics labeling

Wax/resin ribbons are a favorite among mid-range industrial users who need durability and crispness at scale. They’re ideal for smooth, semi-gloss, or coated label materials and perform well in moderate-temperature or humid environments.

When paired with high-performance printers like the GoDEX G530 4" Thermal Transfer Barcode Printer, these ribbons deliver rich, fade-resistant results, making them a top choice for product packaging and compliance labeling.

Compatibility Tip: Always verify that your label stock matches the ribbon formula. Wax/resin ribbons perform best on coated papers or synthetics like polypropylene — ensuring that the ink bonds tightly and won’t flake over time.

Resin Ribbons: Built for Industrial Strength

When labels must survive the harshest conditions — exposure to heat, oil, solvents, or outdoor environments — resin ribbons are the gold standard. These premium ribbons use pure resin compounds that melt at higher temperatures, fusing the ink directly into the label surface.

This produces a print that’s virtually indestructible and resistant to:

- Chemicals and cleaning agents

- Abrasion or scraping

- High heat and UV light

- Industrial wear and tear

Resin ribbons are most often used on synthetic materials like polyester, polypropylene, and vinyl. They’re essential in manufacturing, chemical labeling, electronics, and medical applications where compliance and longevity are critical.

For instance, resin-based printing is commonly used for labeling automotive components or circuit boards that undergo high temperatures during production. The printed details remain legible even after exposure to oils and solvents.

While resin ribbons are more expensive, they drastically reduce reprinting costs over time. If you need labels to last for years rather than months, resin is your best choice.

Choosing the Right Label Material

The ribbon is only half the equation — the label material itself determines print adhesion, resistance, and overall lifespan. Choosing the right substrate depends on your environment, printing volume, and end-use requirements.

Thermal transfer printers can handle a wide variety of materials, from simple paper to industrial-grade synthetics.

Paper Labels: Practical and Cost-Effective

Paper labels remain the go-to choice for many businesses due to their affordability and versatility. They work beautifully with wax or wax/resin ribbons, producing clean, readable prints for moderate conditions.

Common uses:

- Retail price tags

- Barcodes and product IDs

- Office filing and storage labels

- Shipping and logistics tags

Paper labels come in various finishes — matte, semi-gloss, and high-gloss — each affecting how ink adheres to the surface.

If you’re looking for reliable, high-quality paper media, the Thermal Transfer 4” x 6.5” Matte Paper Labels (Fanfolded) is a great option for consistent, efficient printing across large runs. These labels combine smooth feeding performance with strong ink adhesion, ensuring clarity from the first print to the last.

However, paper labels are not designed for high-moisture or outdoor use. Over time, they can absorb humidity and lose adhesion. If you need weatherproofing or chemical resistance, it’s better to invest in synthetic alternatives.

Synthetic Labels: For Durability and Resistance

Synthetic materials like polypropylene, polyester, and vinyl are the preferred choice for heavy-duty environments. They’re engineered to resist water, oil, chemicals, and temperature extremes while maintaining excellent print quality.

- Polypropylene (BOPP) – Highly flexible and cost-effective, great for product packaging and logistics.

- Polyester (PET) – The most durable option, perfect for harsh environments or equipment labeling.

- Vinyl – Offers flexibility with exceptional outdoor resistance.

These materials pair best with wax/resin or resin ribbons, which provide the necessary abrasion and chemical resistance.

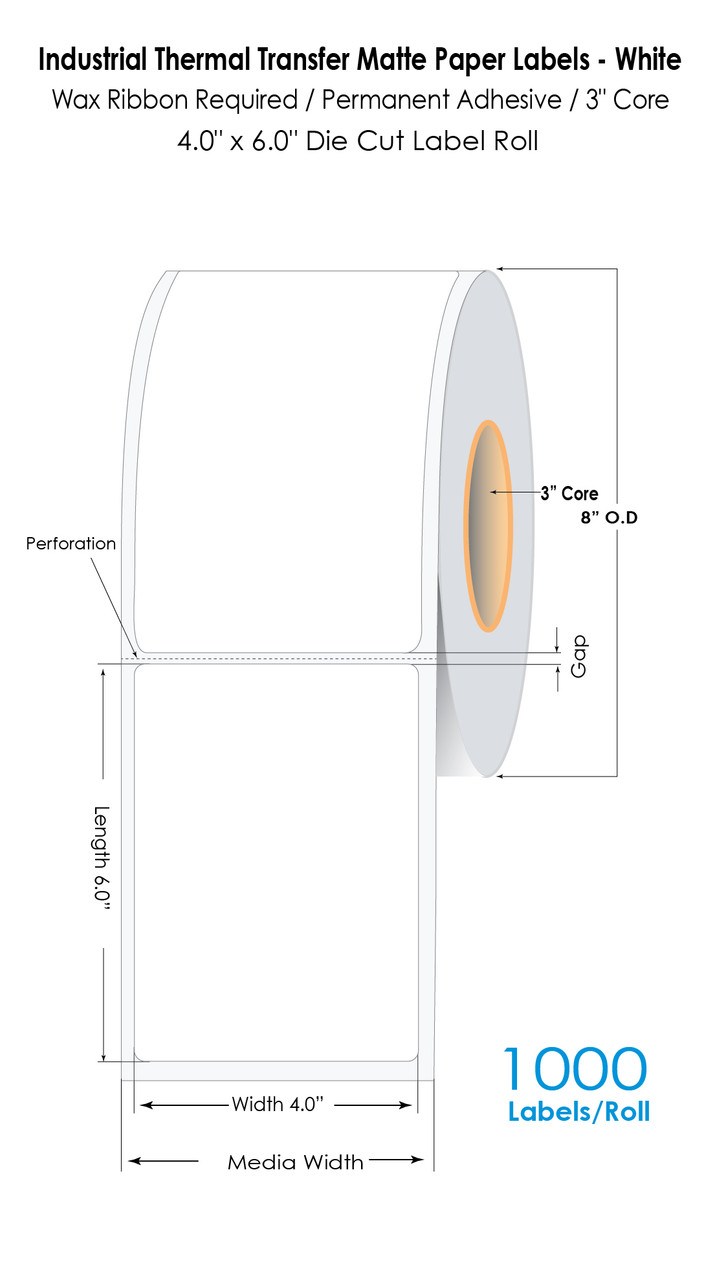

For long-term applications, the Thermal Transfer 4” x 6” White Labels (3” Core) are a versatile choice suitable for logistics, manufacturing, and retail industries that require both durability and precision printing.

Pro Tip: When choosing synthetics, ensure your printer supports higher printhead temperatures. Resin ribbons require more heat to bond properly — printers like the GoDEX G530 are designed to handle this effortlessly.

If your business frequently prints labels that face heat, moisture, or cleaning chemicals, investing in durable materials pays off in the long run. That’s why many professionals turn to DuraFast Label Company for high-performance thermal transfer labels for sale that are specifically engineered to withstand demanding conditions.

Color-Coded and Specialty Labels

Not all labeling is black and white — sometimes, color coding can dramatically improve organization and efficiency.

Color-coded thermal transfer labels help workers quickly identify categories such as product batches, safety levels, or expiration periods. In fast-paced environments like warehouses and hospitals, visual identification can save time and prevent costly mistakes.

The Thermal Transfer 4” x 12” Yellow Floodcoated Label Roll is a prime example. These labels combine high visibility with DuraFast’s consistent adhesive performance, ensuring excellent readability even after prolonged use.

Color-coded options are especially valuable in:

- Inventory management

- Hazard classification systems

- Expiry-based product labeling

- Quality control

Specialty materials — such as metallized films, destructible vinyl, and tamper-evident substrates — also enhance product security and branding flexibility. They can deter counterfeiting and provide traceability, which is critical in regulated industries.

How to Evaluate Label Durability

When assessing materials, consider these factors:

- Adhesion strength: How well does the label bond to your product surface?

- Exposure: Will it face sunlight, heat, or chemicals?

- Handling frequency: Is it a one-time-use label or part of a returnable product?

- Surface texture: Smooth or textured surfaces require different adhesives and materials.

Combining these insights with the right ribbon will ensure optimal durability and appearance.

Why It Pays to Invest in Quality Supplies

Low-cost ribbons or materials might seem appealing, but they often lead to poor adhesion, frequent replacements, and maintenance issues. High-quality supplies not only produce better prints but also extend your printer’s lifespan by reducing residue buildup and heat wear on printheads.

For consistent, professional results, DuraFast Label Company recommends pairing top-tier printers with compatible ribbons and materials. Whether you need to buy thermal transfer printers or restock your consumables, quality is always the deciding factor in performance.

How to Ensure Durability

Durability is the defining feature that sets thermal transfer labels apart from other printing methods. But long-lasting results don’t happen automatically — they require attention to materials, ribbon compatibility, and environmental factors. By mastering these variables, you can produce labels that look and perform perfectly from production to end use.

Matching Ribbons and Materials

The single most important factor in durability is pairing the right ribbon with the right label material. Each ribbon formulation — wax, wax/resin, or resin — is designed for specific surface types and durability levels. A mismatch can lead to faded prints, peeling, or wasted stock.

Here’s a simple compatibility guide:

|

Ribbon Type |

Compatible Material |

Durability Level |

Typical Use |

|

Wax |

Paper (matte or semi-gloss) |

Low–Medium |

Retail, shipping, general office use |

|

Wax/Resin |

Coated paper, polypropylene |

Medium–High |

Logistics, packaging, healthcare |

|

Resin |

Polyester, vinyl, synthetic films |

Very High |

Industrial, chemical, or outdoor use |

The ribbon’s melting point determines how well it fuses with the label surface. Wax melts easily at lower temperatures but smudges under friction; resin, however, requires more heat but becomes part of the label surface, producing unparalleled resistance.

For businesses printing across multiple environments — such as refrigerated storage, warehouses, or outdoor conditions — wax/resin combinations often offer the most practical balance between cost and performance.

Pro Tip: Always perform a ribbon–label test before committing to bulk runs. DuraFast Label Company offers sample kits to help customers test durability and adhesion under real-world conditions.

Environmental Considerations

Even the best label can fail if not suited to its environment. Before choosing your materials, assess the conditions your labels will face throughout their lifecycle.

Heat and Cold

Extreme temperatures can alter adhesive performance and ink bonding. For cold storage or refrigeration, select adhesive formulas rated for low-temperature use and pair them with resin ribbons. For high-heat applications, use synthetic materials that resist softening or curling.

Moisture and Humidity

Water exposure is one of the most common causes of label failure. Paper absorbs moisture and weakens, while synthetics like polypropylene or vinyl remain stable. Resin ribbons are essential here, as they resist water, steam, and condensation without smearing.

Chemicals and Oils

If your labels will come into contact with cleaning solutions, lubricants, or solvents, choose resin-based prints on polyester or vinyl materials. These combinations maintain legibility even after chemical exposure — critical for compliance labeling in laboratories, automotive, or industrial manufacturing.

Friction and Handling

Frequent handling or rubbing can wear down poorly bonded inks. Wax/resin or resin ribbons with higher abrasion resistance are ideal for parts, tools, and machine labels frequently touched or moved.

When it comes to long-term reliability, investing in labels designed specifically for your environmental challenges is far more cost-effective than reprinting due to fading or peeling.

Maintenance Tips for Thermal Transfer Printers

A high-quality printer can last years — but only if properly maintained. Consistent upkeep ensures every label prints sharply, extends printhead life, and minimizes waste.

At DuraFast Label Company, we recommend the following simple but essential practices:

1. Clean Printheads Regularly

Over time, adhesive residue and ribbon particles accumulate on the printhead. This can cause uneven printing or streaking. Clean the printhead with isopropyl alcohol and lint-free swabs after every few rolls of labels or ribbons.

2. Check Ribbon Tension and Alignment

Incorrect ribbon tension can lead to wrinkling, voids, or incomplete transfer. Adjust tension evenly and ensure the ribbon path follows the manufacturer’s guide.

3. Use High-Quality Supplies

Poor-quality ribbons shed more particles, damaging the printhead over time. DuraFast’s ribbons and label rolls are tested to minimize residue and ensure consistent performance.

4. Store Materials Properly

Keep labels and ribbons in a cool, dry area. Avoid direct sunlight or high humidity, which can degrade adhesives and coatings.

5. Update Firmware and Calibrate

Modern printers like the GoDEX G530 include firmware that optimizes heat distribution and speed settings. Regular updates and calibration guarantee the sharpest, most efficient output.

Maintaining your printer isn’t just about preserving hardware — it’s about ensuring every label that leaves your production line reflects professionalism and precision.

Quality Control and Testing

To ensure your labels meet durability and compliance requirements, conduct routine quality checks.

Perform scratch tests, chemical wipe tests, and temperature exposure simulations. DuraFast helps customers establish in-house durability testing routines, ensuring their labeling systems meet ISO, GHS, and other regulatory standards.

By validating your labels before mass deployment, you’ll prevent costly failures downstream.

The Science Behind Label Longevity

The reason thermal transfer labels remain industry-standard in demanding environments comes down to molecular bonding. Unlike inkjet or laser printing, thermal transfer ribbons melt into the surface layer of the label substrate, forming a chemical bond that physically integrates pigment with the coating.

This fusion creates a print that won’t flake or dissolve — even when exposed to external forces like abrasion or moisture. The bond strength varies by ribbon composition: wax provides surface coating, while resin penetrates the top layer for near-permanent marking.

In industrial contexts — especially for barcodes or asset tags that must stay scannable for years — this level of permanence ensures operational efficiency and regulatory compliance.

Industry Applications for Long-Lasting Labels

Thermal transfer labels find uses across nearly every industry sector, from manufacturing and pharmaceuticals to logistics and retail.

Here’s how various industries leverage this technology:

- Pharmaceuticals & Healthcare: For labeling medication bottles, IV bags, or specimen containers that must withstand sterilization and chemical cleaning.

- Manufacturing & Automotive: For durable product IDs, compliance labels, and safety warnings that resist oil, grease, and heat.

- Warehousing & Logistics: For barcodes and inventory labels that remain readable after long storage or shipment cycles.

- Electronics: For small, intricate components where clarity and precision are vital.

- Food & Beverage: For long-term packaging and cold storage applications.

No matter the sector, thermal transfer printing provides the dependability and clarity modern supply chains demand.

Sustainability Considerations

While durability is key, sustainability is becoming increasingly important for manufacturers. DuraFast supports eco-conscious printing by supplying recyclable label materials and ribbons that minimize waste.

Because thermal transfer labels last significantly longer than direct thermal labels, fewer reprints are required, which reduces overall material consumption. Longer label lifespans translate to fewer roll changes, less downtime, and less waste entering the supply chain.

For companies pursuing sustainability certifications, DuraFast offers recyclable cores, liner-free options, and biodegradable adhesives — helping businesses achieve both durability and environmental responsibility.

Print That Lasts

In an era where efficiency, compliance, and brand image all depend on reliability, thermal transfer printing remains the undisputed choice for professional, long-lasting labeling. By combining the right materials, ribbons, and maintenance practices, businesses can produce labels that survive heat, humidity, and handling without losing clarity or adhesion.

Whether you’re labeling thousands of packages in a distribution center or creating compliance tags for industrial equipment, quality thermal transfer labels offer performance that paper or direct thermal alternatives simply can’t match.

At DuraFast Label Company, we help businesses achieve exceptional results with durable, customizable labeling solutions. From premium ribbons to weather-resistant substrates, we ensure your labels meet both performance and compliance standards.

Explore our full range of custom thermal transfer labels designed for every industry and application. Or, if you’re looking for high-performance, ready-to-use thermal transfer labels for sale, you’ll find hundreds of options in different sizes, coatings, and adhesives — all backed by DuraFast’s expertise in industrial printing.

To start improving your labeling reliability and longevity, contact DuraFast Label Company today. Our team will help you find the ideal printer, ribbon, and label combination for your specific operational needs — ensuring every label you print lasts as long as your reputation.