The Science of Waterproof, Heat-Resistant, and Chemical-Proof Labels: What You Need to Know

23rd Dec 2025

What happens when a label is exposed to heat, moisture, or harsh chemicals—and still has to remain readable and intact?

In industries where precision and reliability matter—whether in manufacturing, laboratories, logistics, or food production—a single damaged label can disrupt processes, cause compliance issues, or lead to costly mistakes. In 2024, 45.5% of food product recalls were linked to labelling errors, including unreadable or degraded labels. These numbers highlight the growing need for durable labelling solutions designed to perform in extreme conditions.

At DuraFast Label Company, we understand that not all labels are created equal. Labels that can resist heat, moisture, and chemicals require specific materials, coatings, and printing technologies—each chosen for the conditions the label will face. We’ve spent years helping Canadian businesses and industries find the right labelling systems that maintain clarity, adhesion, and compliance, no matter the environment.

In this article, we take a closer look at the science behind durable industrial labels—those that are waterproof, heat-resistant, and chemical-proof. We’ll examine how material composition, coating types, and print technologies work together to create labels that endure the toughest conditions. We’ll also discuss best practices for selecting the right label for your application and touch on the innovations that continue to shape industrial labelling in 2025 and beyond.

1. Why Label Durability Matters More Than Ever

Durable labels are not a luxury—they are a necessity across sectors like healthcare, automotive, petrochemical, and food packaging. When labels fail, operations can grind to a halt. A shipping label that smears due to moisture exposure, or a warning label that fades after contact with cleaning agents, can result in safety hazards and non-compliance with regulatory standards.

Here’s why durable labelling has become a cornerstone of modern industry:

- Compliance and safety: Regulatory bodies in Canada and abroad require permanent, legible identification for chemical containers, equipment, and consumer products. Labels that fade or peel compromise compliance.

- Operational efficiency: Reliable labels streamline tracking and inventory management, preventing costly downtime or rework.

- Brand reputation: A damaged or unreadable label can give the impression of poor quality control.

- Environmental exposure: Outdoor applications expose labels to UV light, temperature fluctuations, and moisture—conditions that demand high-performance materials.

This is where chemical-proof labels stand out. They are engineered not just for durability but for resilience against solvents, oils, and corrosive substances that would destroy standard paper or film labels within hours.

2. The Science of Material Selection

At the core of every durable label is its substrate—the base material that determines its performance. Let’s look at how different materials contribute to the creation of waterproof, heat-resistant, and chemical-proof labels.

2.1 Synthetic vs. Paper Materials

Paper labels, while cost-effective and easy to print, have limited resistance to environmental stress. They can absorb moisture, disintegrate under heat, and degrade when exposed to chemicals. Synthetic materials, on the other hand, are specifically formulated to withstand extreme environments.

Common synthetic substrates include:

- Polyester (PET): Offers exceptional chemical resistance, dimensional stability, and high-temperature tolerance (up to 150°C). Ideal for nameplates, rating labels, and asset tracking.

- Polypropylene (PP): Resistant to moisture and moderate heat, commonly used for packaging and logistics labels.

- Vinyl: Highly flexible and durable, used for applications that require both chemical and weather resistance. Vinyl labels in Canada are especially popular for outdoor use and equipment marking.

- Polyimide: Handles extremely high temperatures (up to 300°C), often used for printed circuit boards and electronics manufacturing.

Each material brings a balance of flexibility, adhesion, and print quality that can be tailored to the demands of the environment.

2.2 How Film Thickness Affects Performance

Film thickness influences both durability and application. Thicker films (2–4 mils) are preferred for industrial applications requiring abrasion resistance, while thinner films (1–2 mils) work best for product packaging or curved surfaces.

The adhesion system must also match the substrate surface—metal, glass, plastic, or powder-coated finishes. Poor pairing between adhesive and substrate leads to premature label failure, even if the label material itself is resilient.

3. Coatings and Laminates: The Unsung Heroes of Durability

Even the toughest substrate can degrade without the right protective topcoat or laminate. Coatings and laminates shield printed surfaces from physical abrasion, moisture, and UV radiation while preserving print clarity.

3.1 Protective Coatings

Protective coatings are thin layers applied to the label surface to enhance resistance and prolong lifespan. The most common include:

- UV coatings: Block ultraviolet light that causes fading and degradation of ink.

- Varnishes: Provide a glossy or matte finish while sealing the surface against mild abrasion and water.

- Chemical-resistant coatings: These use silicone or fluoropolymer compounds that repel aggressive solvents and oils.

3.2 Laminates

Laminates offer the highest level of protection by encapsulating the printed image between multiple film layers. Laminated labels can withstand exposure to oils, fuels, and cleaning agents—making them ideal for oil change labels, industrial equipment tags, and outdoor signage.

There are two major types:

- Thermal laminates:Heat-applied films used for high-durability applications.

- Pressure-sensitive laminates:Self-adhesive films added post-print for flexible production.

Laminates also add rigidity, which can be beneficial in applications like compliance and asset tracking labels, where structural integrity matters.

4. Printing Technologies Behind Durable Labels

Material selection and coating are only part of the equation. The printing technology used determines how well the image bonds to the surface and how long it will last. Let’s examine the leading printing methods for waterproof, heat-resistant, and chemical-proof labels.

4.1 Thermal Transfer Printing

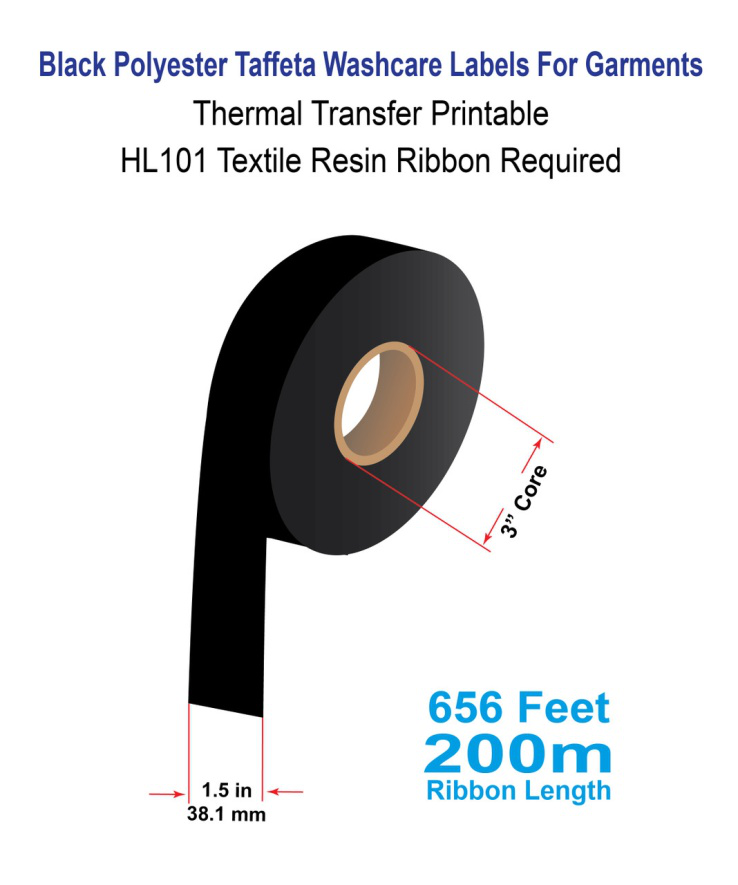

Thermal transfer printing is the benchmark for long-term durability. It uses heat to transfer resin or wax-resin ribbons onto the label surface, producing sharp, smudge-proof text and barcodes.

Advantages:

- Excellent resistance to moisture, chemicals, and heat.

- High-definition printing for barcodes and fine text.

- Compatible with a wide range of custom thermal transfer labels.

For industries requiring permanent identification—like electronics, automotive, and chemical processing—thermal transfer printing is the preferred choice.

Tip: When sourcing thermal transfer labels, always pair the ribbon type (resin, wax, or wax-resin) with the correct substrate. Resin ribbons offer superior chemical and abrasion resistance for synthetic labels.

4.2 Direct Thermal Printing

Direct thermal labels are created by applying heat directly to a heat-sensitive coating on the label, eliminating the need for ribbons. This method is efficient and cost-effective for short-term use, such as shipping or food labelling.

However, direct thermal labels are sensitive to prolonged heat and light exposure, so they are best suited for indoor or temporary applications.

Recent innovations, including improved topcoats and stabilizers, have extended their lifespan, making them a viable option for some industrial environments.

4.3 Inkjet Printing

Inkjet technology—especially when using pigment-based inks—delivers vibrant colours and high-resolution graphics. Blank inkjet labels are widely used for product packaging, retail, and custom branding where visual appeal matters as much as durability.

Pigment inks, as opposed to dye-based inks, provide better resistance to UV light and moisture. For outdoor or chemical-resistant applications, affordable blank inkjet labels can be coated with laminates or printed using pigment-based systems to extend their life.

4.4 Laser Printing

Laser sheet labels, available in various finishes and adhesives, are another option for industrial and office environments. Laser printing fuses toner to the label surface using heat, creating a smudge-resistant and durable image.

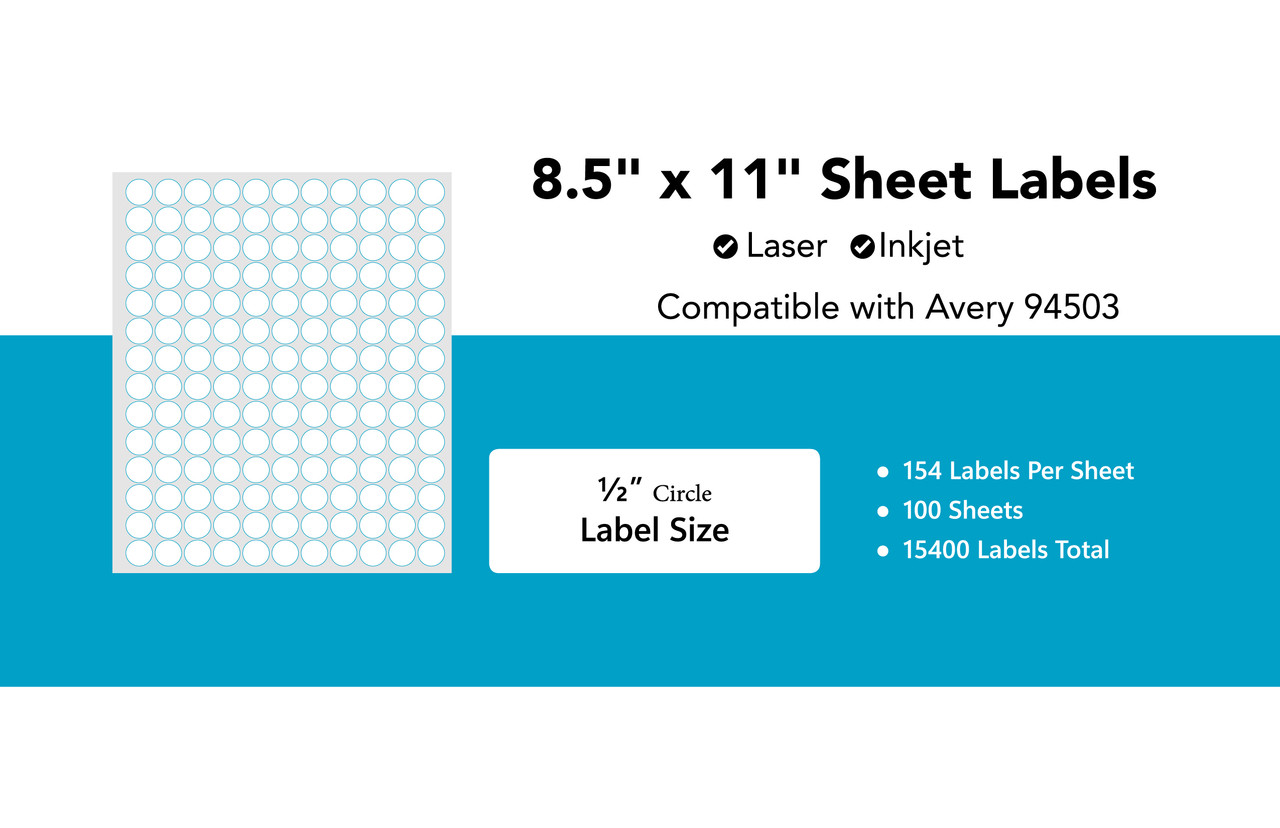

Buy laser sheet labels online in configurations suited to your printer model and application—whether for safety data sheets, product packaging, or compliance documentation.

5. Resistance Factors: What Each Label Type Can Withstand

Let’s analyse how different label systems perform under specific environmental conditions.

5.1 Moisture and Water Exposure

To qualify as weatherproof labels, a label must remain intact and legible even after direct water contact or immersion. Synthetic films like polypropylene, polyester, and vinyl, combined with strong adhesives, are ideal for waterproofing.

For additional moisture resistance:

- Use laminated or UV-coated labels.

- Avoid paper-based materials.

- Choose permanent adhesives that bond well even on wet or uneven surfaces.

Applications include beverage bottling, outdoor signage, marine products, and logistics operations.

5.2 Heat Resistance

Labels exposed to elevated temperatures—such as those in manufacturing, automotive, or kitchen environments—require materials that maintain integrity under heat stress.

Suitable materials and systems include:

- Polyimide labels for electronics (up to 300°C).

- Polyester labels for general high-temperature use (up to 150°C).

- Resin-based thermal transfer ribbons for heat stability.

5.3 Chemical Resistance

The most challenging environments involve exposure to cleaning agents, solvents, fuels, or industrial oils. Chemical-proof labels are designed to survive such conditions through a combination of material science and protective coatings.

They resist degradation when exposed to substances like:

- Acetone

- Isopropyl alcohol

- Brake fluid

- Sodium hydroxide

- Diesel and gasoline

- Hydraulic oils

Applications include:

- Laboratory containers and vials

- Industrial drums and pipelines

- Automotive parts and service tags

- Hazardous materials identification

These labels must maintain print legibility and adhesive strength even after repeated exposure.

6. Adhesive Chemistry: The Foundation of Staying Power

A label’s performance often depends more on its adhesive than its surface material. Advanced adhesive technologies determine how well the label sticks to challenging surfaces or withstands fluctuating conditions.

6.1 Permanent Adhesives

Designed for long-term applications, these adhesives offer high initial tack and strong bonding. They are ideal for metal, glass, or textured plastics where permanent identification is needed.

6.2 Removable Adhesives

Used when labels must be replaced or repositioned without leaving residue. While not typically suited for high-stress environments, they are common in logistics and retail applications.

6.3 High-Temperature Adhesives

For heat-resistant labels, the adhesive must maintain strength under sustained heat. Silicone-based adhesives perform exceptionally well, retaining adhesion even beyond 200°C.

6.4 Chemical-Resistant Adhesives

In environments with frequent solvent or oil exposure, acrylic-based adhesives provide chemical stability and resistance to yellowing or degradation.

7. Testing and Standards for Label Durability

Industrial labels undergo rigorous testing to ensure they meet regulatory and performance standards. Some of the key tests include:

- Chemical immersion tests: Measure resistance to cleaning solutions, solvents, and fuels.

- Abrasion testing: Evaluates how labels withstand friction and mechanical wear.

- UV exposure testing: Assesses how materials resist sunlight and weathering.

- Temperature cycling: Simulates extreme temperature shifts to test adhesion and print stability.

- Peel adhesion testing: Determines bond strength between the adhesive and substrate.

Compliance with UL (Underwriters Laboratories), CSA (Canadian Standards Association), and BS5609 (marine durability) certifications assures that the labels meet international standards for chemical and environmental performance.

8. Common Industrial Applications for Durable Labels

Durable labelling technology has countless industrial uses. Below are some common applications where chemical-proof labels and related systems are indispensable:

8.1 Automotive and Mechanical Servicing

Oil change labels that resist grease, heat, and abrasion.

- Under-the-hood components requiring heat and chemical stability.

- VIN and compliance labels on vehicles.

8.2 Chemical Manufacturing and Laboratories

- Containers, beakers, and pipelines requiring chemical-proof labelsfor identification.

- Lab-grade adhesives that resist solvents and sterilisation.

8.3 Food and Beverage Production

- Weather-resistant and waterproof labels for refrigerated or frozen packaging.

- Wash care label printersused for labelling containers and cleaning supplies in food-safe environments.

8.4 Healthcare and Pharmaceuticals

- Labels for medical devices, vials, and laboratory samples.

- Chemical- and moisture-resistant coatings to prevent label degradation during sterilisation.

8.5 Outdoor and Industrial Equipment

- Vinyl labelsfor long-term exposure to UV, water, and abrasion.

- Warning or safety labels for heavy machinery and outdoor assets.

8.6 Retail and E-commerce

- Laser sheet labels for high-quality branding and packaging.

- Direct thermal labels for shipping and logistics.

9. Innovations in Durable Label Printing

The technology behind durable labelling continues to evolve, driven by environmental responsibility and the demand for performance.

9.1 Eco-Friendly Durable Materials

Manufacturers are developing recyclable and biodegradable synthetic films that maintain high performance while reducing environmental impact. Water-based adhesives and solvent-free coatings are gaining popularity in Canada for sustainable production.

9.2 Advanced Ink Formulations

Modern pigment inks and resin-based ribbons deliver enhanced resistance to UV light, chemicals, and abrasion. These formulations also produce deeper, more stable colours for improved readability and branding.

9.3 Smart Labels and Industrial IoT

Durable labels are increasingly integrated with RFID and NFC technologies, allowing for smart asset tracking in extreme environments. These systems enable automation and monitoring without compromising label resilience.

9.4 Hybrid Printing Systems

Hybrid label printers now combine thermal and inkjet technologies, giving manufacturers greater flexibility for both durable and high-resolution output. While certain models like Epson ColorWorks are widely recognised, our focus remains on compatible consumables and on Afinia, Primera Technology, and VIPColor systems that deliver exceptional quality and cost efficiency.

10. Choosing the Right Label for Your Application

Selecting the right label is not just about picking a durable material—it requires a holistic understanding of the environment, the intended use, and the long-term demands on the label. A label that performs well in one situation may fail catastrophically in another. By carefully evaluating key factors, you can ensure your labels remain legible, adhesive, and intact under even the most challenging conditions.

Here’s a detailed guide to help you make informed choices:

10.1 Identify Environmental Exposure

The first step in choosing the right label is to understand the conditions it will face. This involves assessing:

- Temperature extremes: Will the label be exposed to high heat, freezing temperatures, or frequent temperature cycling? For example, labels on automotive engine components must withstand elevated heat, while freezer labels need to resist cracking at sub-zero temperatures.

- Moisture and humidity: Outdoor applications, refrigerated products, or high-humidity environments demand waterproof or water-resistant labels. Labels for beverages or laboratory containers, for instance, must remain intact even after repeated condensation or washing.

- Chemical exposure: Industrial, laboratory, and automotive labels may encounter oils, solvents, acids, or cleaning agents. In these cases, chemical-proof labels are essential to prevent degradation and ensure compliance.

- Mechanical stress: Will the label be subjected to abrasion, scratching, or repeated handling? Labels on machinery, shipping containers, or handheld equipment need reinforced substrates or protective laminates.

- UV and light exposure: Outdoor applications require resistance to fading caused by sunlight. UV-protected coatings or weatherproof vinyl labels help maintain readability over time.

Understanding these environmental factors forms the foundation for choosing the correct material, adhesive, and print method.

10.2 Choose the Correct Material

Once the exposure conditions are clear, selecting the right substrate is the next step. The substrate determines not only durability but also compatibility with printing methods. Common materials include:

- Polyimide: Ideal for extreme heat applications, such as electronics or automotive under-the-hood components. Polyimide maintains structural integrity and adhesive strength even at temperatures exceeding 300°C.

- Vinyl: Highly flexible and weather-resistant, vinyl is excellent for outdoor labels, equipment markings, and surfaces that require bending or conforming to curves. Its chemical resistance also makes it suitable for oily or wet environments.

- Polyester (PET): Offers a balance of chemical resistance, heat tolerance, and dimensional stability. Commonly used for industrial asset tags, safety labels, and laboratory equipment.

- Polypropylene: Moisture-resistant and moderately heat-tolerant, suitable for packaging, beverage containers, and labelling products exposed to wet conditions.

Selecting the right material is critical because it ensures the label substrate itself won’t fail even before considering adhesive or print durability.

10.3 Match the Adhesive

A high-quality label can still fail if the adhesive does not suit the surface or environment. Adhesive choice should align with substrate type, surface material, and environmental conditions:

- Permanent adhesives: Provide long-term bonding for labels on metal, glass, or plastic surfaces. Essential for compliance tags, serial numbers, and asset tracking.

- Removable adhesives: Allow labels to be repositioned or removed without leaving residue. Suitable for temporary labels, shipping tags, or price stickers.

- High-temperature adhesives: Maintain adhesion under sustained heat, commonly silicone-based. Critical for engine components, electronics, or industrial ovens.

- Chemical-resistant adhesives: Acrylic-based adhesives provide strong bonding and resist degradation from exposure to solvents, oils, and industrial cleaning agents.

Matching the adhesive to the surface texture (smooth, rough, powder-coated) is equally important. Smooth surfaces often require permanent adhesives for full contact, whereas textured surfaces may need more aggressive formulations or mechanical bonding features.

10.4 Select a Compatible Printing Method

Even the most durable label material can fail if the printing method is inappropriate for the application. Choosing the right print technology ensures the image or text remains legible over time:

- Thermal transfer printing: Ideal for chemical-proof labels and industrial applications. Resin ribbons combined with polyester or polyimide substrates produce sharp, smudge-proof images that withstand heat, moisture, and chemical exposure. This method is widely used for barcodes, serial numbers, and warning labels.

- Direct thermal printing: Efficient for short-term applications like shipping labels or retail tags. While cost-effective, direct thermal labels are sensitive to heat and UV light, limiting long-term outdoor use.

- Inkjet printing: Suitable for high-resolution graphics and vibrant colour applications. Pigment-based inks offer improved resistance to UV, moisture, and mild chemicals, making them a practical choice when visual presentation and durability must coexist. Affordable blank inkjet labels can be combined with coatings for extended life.

- Laser printing: Provides smudge-resistant, durable images on laser sheet labels. Best for office or industrial documentation where high heat or solvent exposure is limited.

Selecting a printing method that complements the label material and environment ensures maximum longevity.

When Durability Meets Science: Why Industrial Labels Matter

Have you ever considered how much information a single label carries—and what happens if it disappears? From safety data to expiry dates, product identification to compliance details, labels are silent workhorses in every industry. Their reliability reflects not only the quality of the product but also the professionalism of the business behind it.

At DuraFast Label Company, we specialise in helping Canadian businesses select the right labelling materials and consumables to meet their operational demands. Whether you’re sourcing chemical-proof labels, weatherproof options for outdoor use, or custom thermal transfer labels for industrial applications, we offer one of the most comprehensive selections of durable labelling supplies in Canada.

Our range includes:

- Vinyl and polyester labels for outdoor and industrial use.

- Direct and thermal transfer labels for logistics, chemical, and manufacturing sectors.

- Laser and inkjet-compatible labels for office and retail needs.

- Wash care label printers and accessories for textile or cleaning applications.

Every product we offer is backed by expert support and technical guidance to help you choose the right combination of material, adhesive, and print method.

If your business depends on labels that can endure heat, moisture, or chemicals without compromise, trust us to provide the right solution. Contact DuraFast Label Company today to learn how our durable label materials and printing supplies can help your operations perform better, longer, and more reliably.