The Hidden Costs of Poor Label Quality: How to Avoid Smudging, Fading, and Peeling Issues

26th Dec 2025

What happens when your product label smudges before it even reaches the shelf, fades under fluorescent lighting, or starts peeling after exposure to moisture or heat? For many businesses, the damage goes far beyond a cosmetic flaw. Inconsistent or poor label quality can erode customer trust, lead to regulatory non-compliance, and even cause expensive product recalls.

According to a recent global packaging study, many consumers say that damaged or faded labels make them question the quality of a product itself. In industrial and retail environments, a poorly printed barcode or peeling label can lead to lost sales, tracking errors, or safety violations. For sectors like food and beverage, healthcare, and manufacturing—where accurate labelling is both a brand promise and a legal requirement—the consequences can be even more severe.

At DuraFast Label Company, we’ve seen how businesses can lose thousands of dollars each year due to label failures that could have been prevented with the right materials, printers, and coatings. Our mission has always been to help companies avoid these hidden costs by providing high-quality label solutions designed for performance, compliance, and durability.

In this blog, we’ll look closely at what causes poor label quality, how smudging, fading, and peeling can impact both brand reputation and bottom line, and what practical steps you can take to avoid these costly problems. We’ll also discuss how the right choice of label material—such as weatherproof vinyl, durable thermal transfer, or chemical-resistant options—can make all the difference.

1. The True Cost of Poor Label Quality

Labels do more than identify a product—they communicate value, ensure compliance, and maintain traceability. Yet when the quality of those labels is compromised, businesses often underestimate how expensive those failures can be.

1.1. The Visible and Hidden Consequences

The obvious consequence of poor label quality is aesthetic. Smudged text or peeling edges immediately give an impression of poor manufacturing standards. However, the hidden costs often run much deeper:

- Product returns or recalls: Inaccurate or unreadable information can lead to non-compliance or consumer confusion.

- Production downtime: Reprinting defective labels slows operations.

- Inventory issues: Scanning failures due to faded barcodes cause tracking errors.

- Loss of brand trust: Damaged labels can make customers question your overall quality control.

- Increased waste: Worn or unusable labels end up discarded, wasting ink, ribbons, and materials.

In short, a small issue at the print stage can cascade into financial losses, reputational damage, and compliance risks.

1.2. Why Poor Label Quality Happens

The root causes of poor label performance usually stem from one or more of the following:

- Incompatible materials: Using paper labels for applications that require waterproof or chemical-resistant materials.

- Incorrect printer settings: Wrong temperature, pressure, or speed in thermal printers.

- Low-quality adhesives: Inferior adhesives that fail under heat, cold, or moisture.

- Environmental exposure: Sunlight, oil, and humidity can degrade certain labels quickly.

- Improper storage: Labels stored in damp or warm environments before use often lose adhesion or curl.

- Subpar print technology: Using outdated or incompatible printers or inks.

By understanding these root causes, businesses can make informed choices to prevent label failures before they occur.

2. Smudging: The Enemy of Professionalism and Legibility

Smudging is one of the most common and frustrating label problems. It happens when ink or toner fails to set properly on the label surface or when handling occurs too soon after printing.

2.1. How Smudging Happens

Smudging often results from:

- Improper ink absorption: Certain label materials are not designed for liquid-based inks.

- Low-quality coatings: Coatings that don’t allow proper ink bonding.

- Incorrect printer settings: Too much ink or slow drying speeds.

- Environmental factors: High humidity prevents ink from drying efficiently.

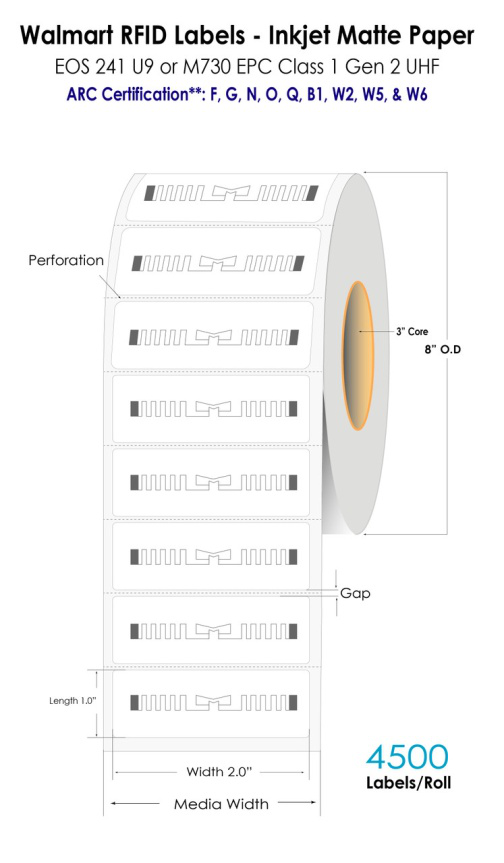

For instance, when printing on blank inkjet labels, it’s essential to choose those designed for the type of ink—dye or pigment—you’re using. Pigment-based inks, when paired with properly coated inkjet labels, deliver water-resistant prints that won’t smear even under wet conditions.

2.2. The Impact of Smudging on Business

- Brand perception: A smudged label instantly looks unprofessional.

- Compliance issues: Regulatory text or hazard symbols may become illegible.

- Operational delays: Smudged barcodes won’t scan, slowing logistics.

- Customer frustration: End-users may struggle to read care instructions or expiry dates.

For wash care label printers used in textile manufacturing, smudging can be disastrous. If laundry instructions blur after the first wash, it can lead to product damage, returns, and a loss of trust in your brand.

2.3. How to Prevent Smudging

Here are practical steps to keep labels crisp and clean:

- Use quality inkjet or laser-compatible materials. Always match the label’s coating to the printer type.

- Control humidity and temperature in your printing environment.

- Test print settings on small batches before full production.

- Invest in proven printers such as those from Afinia Label, Primera Technology, or VIPColor, designed for high-precision output.

- Choose water-resistant labels for applications prone to moisture exposure, such as food packaging or industrial use.

Smudging is preventable with the right material-printer combination and controlled printing conditions.

3. Fading: When Labels Lose Their Voice

Over time, exposure to sunlight, heat, or chemicals can cause label print to fade. Faded labels not only look worn but can compromise compliance and traceability.

3.1. What Causes Label Fading

Fading primarily occurs due to:

- UV exposure: Ultraviolet light breaks down ink pigments and dyes.

- Heat exposure: Excessive heat softens adhesive layers and damages print integrity.

- Chemical exposure: Cleaning agents, oils, or solvents can dissolve inks.

- Low-quality inks: Dye-based inks tend to fade faster than pigment-based alternatives.

- Unprotected surfaces: Labels without a laminate or varnish coating are more vulnerable.

A common mistake is using direct thermal labels in environments with long shelf lives. While direct thermal printing is fast and economical, the labels are sensitive to light and heat. For long-term labelling, thermal transfer labels are a more durable choice because they use ribbons that bond the ink directly to the label surface.

3.2. The Business Risks of Faded Labels

- Loss of product identity: Colours and logos fade, reducing brand visibility.

- Non-compliance: Expiry dates or batch numbers become unreadable.

- Operational confusion: In warehouses, faded barcodes slow scanning and order fulfilment.

- Negative customer perception: A faded label gives the impression of old or expired stock.

For automotive workshops, for example, faded oil change labels can lead to missed maintenance reminders and lost repeat business. Similarly, in retail, faded price or SKU labels can cause costly checkout delays.

3.3. Preventing Label Fading

- Use pigment-based inks for better UV resistance.

- Choose weatherproof labels with UV-protective coatings or laminates.

- Avoid prolonged exposure to direct sunlight when possible.

- Select label materials specifically designed for chemical or heat resistance, such as vinyl or polyester.

- Use thermal transfer ribbons that match the label’s durability requirements—wax/resin or full resin for maximum fade resistance.

A simple switch from paper to vinyl labels can dramatically extend label life, especially for outdoor or industrial use.

4. Peeling: The Silent Saboteur of Product Presentation

Peeling labels can quickly ruin even the most beautifully designed packaging. They occur when adhesives fail to bond properly or lose tack over time.

4.1. Common Causes of Peeling

- Improper surface preparation: Dust, oil, or moisture prevents adhesion.

- Incorrect adhesive choice: Not all adhesives work on every surface type.

- Temperature extremes: Cold surfaces make adhesives rigid; heat softens them.

- Over-handling: Frequent contact weakens the adhesive layer.

- Low-quality liners or facestocks: Cheap materials compromise overall adhesion.

Even premium printing can’t compensate for a poor adhesive bond. Choosing the right adhesive—permanent, removable, or repositionable—matters as much as the label material itself.

4.2. The Cost of Peeling Labels

Peeling may seem minor, but the impact is significant:

- Damaged branding: A half-detached label makes even a premium product appear low quality.

- Lost traceability: Once a barcode peels off, the product can’t be tracked.

- Increased rework: Staff must manually replace failed labels, wasting time.

- Customer complaints: Consumers may think the product was tampered with.

In manufacturing and logistics, peeling labels can also cause compliance failures if they detach during shipping, making products untraceable.

4.3. How to Prevent Peeling

- Clean and dry surfaces before application.

- Choose adhesives designed for your environment (freezer-grade, high-tack, removable, etc.).

- Apply labels with consistent pressure and allow adhesive curing time.

- Select durable substrates such as polyester or vinyl for long-term adhesion.

- Avoid moisture exposure immediately after application.

For industrial or outdoor use, weatherproof labels with strong adhesives perform reliably on metal, glass, and plastic surfaces—even under fluctuating temperatures.

5. Material Matters: Choosing Labels That Last

Not all labels are created equal. The right material choice is often the difference between reliable performance and recurring problems.

5.1. Common Label Materials and Their Uses

|

Material Type |

Key Features |

Ideal Applications |

|

Paper |

Cost-effective, easily printable |

Short-term indoor use |

|

Polypropylene (BOPP) |

Moisture-resistant, flexible |

Food packaging, cosmetics |

|

Vinyl |

Weatherproof, tear-resistant |

Industrial, outdoor, automotive |

|

Polyester (PET) |

High-temperature resistance |

Electronics, machinery |

|

Polyimide |

Extreme heat durability |

Circuit boards, aerospace |

|

Fabric |

Soft and flexible |

Wash care and apparel tags |

When long-term durability is needed, vinyl labels and polyester labels stand out. They resist moisture, sunlight, and harsh chemicals, making them ideal for industrial settings.

5.2. Matching Labels to Printing Technologies

Each printer type has unique material compatibility requirements:

- Inkjet Printers: Work best with coated paper or film materials. Pair them with affordable blank inkjet labels for sharp, vibrant results.

- Laser Printers: Require heat-resistant materials like polyester or vinyl. If you print in bulk, you can buy laser sheet labels online for efficient production.

- Thermal Transfer Printers: Use ribbons to produce highly durable prints suitable for long-term storage or outdoor use.

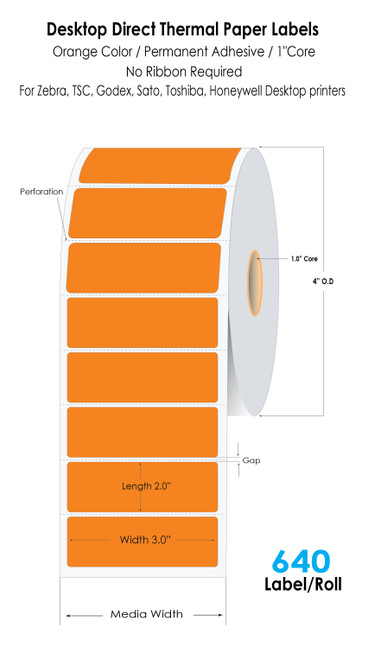

- Direct Thermal Printers: Fast and cost-effective for short-term applications, but labels are heat-sensitive.

If your business relies on wash care label printers or needs to maintain long-lasting readability, always choose thermal transfer or laser-compatible materials for maximum durability.

6. Environmental and Application Considerations

Even the best labels can fail if not matched to their environment.

6.1. Moisture and Water Exposure

Industries like beverages, cosmetics, and cleaning supplies often deal with wet or humid environments. Here, weatherproof labels are essential. They feature:

- Water-resistant coatings that prevent smudging and ink bleeding.

- Strong adhesives that hold up under condensation.

- Synthetic facestocks like vinyl or polypropylene for durability.

6.2. Heat and Cold

Labels exposed to temperature fluctuations need specialized adhesives:

- High-temperature adhesives for machinery or automotive parts.

- Freezer-grade adhesives for frozen foods and pharmaceuticals.

Thermal transfer labels with full-resin ribbons are best for such environments since they withstand heat without fading or peeling.

6.3. Chemical Exposure

In labs or manufacturing, labels often encounter solvents, oils, and cleaning agents. Use:

- Polyester or vinyl materials for chemical resistance.

- Full-resin ribbons that bond ink to the label surface.

- Laminated finishes for added protection.

6.4. Surface Type

The texture and composition of a surface affect adhesion. For instance:

- Smooth surfaces like glass or metal bond well with standard adhesives.

- Rough or curved surfaces may require flexible or high-tack materials.

- Fabric or rubber needs specialized label solutions.

Understanding these factors ensures that each label performs as expected throughout its lifecycle.

7. Printing Techniques and Quality Control

Even with the best materials, the printing process determines final label performance.

7.1. Printing Techniques to Enhance Quality

- Thermal Transfer Printing: Ideal for durable, long-lasting results. Use resin ribbons for outdoor or industrial labels.

- Laser Printing: Produces sharp, heat-resistant prints with minimal smudging. Perfect for barcode and product labels.

- Inkjet Printing: Delivers vibrant, full-colour designs on compatible media. Works best with coated or glossy blank inkjet labels.

For short-term retail or shipping labels, direct thermal labels provide excellent speed and efficiency. However, for long-term identification, custom thermal transfer labels are a smarter choice.

7.2. Quality Control Measures

To ensure consistent label quality:

- Regularly calibrate printers and replace worn components.

- Use OEM inks and ribbons rather than low-cost alternatives.

- Conduct adhesion and fade tests under expected conditions.

- Inspect print alignment and barcode readability.

- Store labels properly in a cool, dry place away from sunlight.

Preventive quality checks can save significant reprinting and replacement costs in the long run.

8. Industry Examples: Where Label Quality Makes or Breaks Success

8.1. Food and Beverage

Labels must remain readable despite moisture and refrigeration. Poor label quality here can lead to contamination risk or compliance issues.

8.2. Healthcare and Pharmaceuticals

Regulations demand legible, durable labels that resist chemicals and sterilisation. Peeling or fading can have legal implications.

8.3. Automotive and Industrial

In harsh environments, oil change labels and part identifiers must withstand grease, heat, and mechanical wear. Only high-grade weatherproof or vinyl labels can deliver reliable performance.

8.4. Retail and Apparel

Wash care label printers ensure instructions remain intact after repeated washing. Poor-quality fabric labels can frustrate customers and damage brand perception.

8.5. Logistics and Warehousing

Scannable barcodes are essential for tracking. Thermal transfer labels maintain legibility over time, unlike direct thermal labels that darken with age.

9. Sustainability and Label Quality: Why Durable Labels Are an Eco-Responsible Choice

In today’s business environment, sustainability is no longer optional—it’s a critical consideration for both consumers and companies. One often-overlooked aspect of sustainable operations is label quality. While labels may seem like a minor component of your product, their durability—or lack thereof—can have significant environmental and operational impacts.

9.1. The Environmental Cost of Poor Labels

When labels fail prematurely due to smudging, fading, or peeling, the consequences extend far beyond visual appeal:

- Increased Material Waste: Each failed label must be discarded, often along with the product packaging it is attached to. Over time, this leads to significant waste of paper, film, adhesives, and ink.

- Higher Energy Consumption: Reprinting labels consumes additional energy, whether through inkjet, laser, or thermal transfer printing, increasing your carbon footprint.

- Transportation Footprint: Failed labels often result in returns, replacements, or reshipments, which increase fuel consumption and greenhouse gas emissions.

- Chemical Waste: Low-quality labels may require frequent use of inks, solvents, or adhesives that are less eco-friendly. Repeated reprinting amplifies this environmental burden.

In short, poor label quality contributes directly to environmental inefficiency, making durability a central part of any sustainability strategy.

9.2. Choosing High-Quality, Long-Lasting Materials

Selecting the right label materials can significantly reduce waste while maintaining performance. Here are key considerations:

- Vinyl Labels: Vinyl is highly durable, resistant to moisture, UV exposure, and chemicals. A single vinyl label can often outlast multiple paper labels, reducing the need for replacements. Vinyl labels are ideal for outdoor products, industrial equipment, and automotive applications where environmental exposure is unavoidable.

- Laser Sheet Labels: These labels are designed for high-precision printing, offering consistent quality over large production runs. By preventing smudging and peeling, they reduce the frequency of reprints and material wastage.

- Polyester and Synthetic Labels: Resistant to tearing, heat, and chemical exposure, synthetic labels provide longevity in harsh environments. Fewer replacements mean fewer materials consumed and less waste generated over time.

By choosing long-lasting label materials, businesses reduce the number of failed labels, lower operational waste, and contribute to a more sustainable production cycle.

9.3. Eco-Friendly Adhesives and Facestocks

Durable labels are not only about the substrate—they also require adhesives and coatings designed with sustainability in mind:

- Recyclable Facestocks: Many modern labels use facestocks made from recyclable paper or synthetic films, which can be reclaimed during recycling streams rather than ending up in landfills.

- Eco-Friendly Adhesives: Some adhesives are formulated to be non-toxic and biodegradable, reducing environmental impact when the labels are disposed of.

- Water-Based or Solvent-Free Inks: Using environmentally friendly inks for printing further reduces chemical pollution while maintaining print quality.

By combining durable substrates with sustainable adhesives and inks, companies can significantly reduce their environmental footprint without compromising on label performance.

9.4. Operational and Brand Benefits of Sustainable Labels

Investing in high-quality, eco-conscious labels is not only good for the planet—it also benefits your business in practical ways:

- Reduced Operational Waste: Fewer failed labels mean less time and materials spent on reprinting, saving both money and resources.

- Consistent Brand Presentation: Durable labels maintain their appearance throughout the product lifecycle, reinforcing a professional and responsible image.

- Consumer Trust: More customers are making purchasing decisions based on environmental responsibility. Using sustainable labels signals that your brand is committed to ethical practices.

- Regulatory Compliance: Certain industries, including food, beverage, and healthcare, are increasingly subject to environmental and packaging regulations. Using recyclable, durable labels helps businesses stay compliant.

10. How to Choose the Right Label Supplier

Partnering with the right supplier can save you countless operational headaches. Look for a company that offers:

A wide range of label materials and adhesives.

- Expert guidance on printer compatibility.

- Customisation options for shape, size, and coating.

- Quick turnaround times and local support.

When Label Quality Defines Your Brand

What does your label say about your brand when customers first see it? A crisp, vibrant, and durable label silently communicates reliability, attention to detail, and quality. On the other hand, peeling, faded, or smudged labels convey neglect and inconsistency—messages no business wants to send.

At DuraFast Label Company, we understand how costly poor label quality can be. That’s why we supply one of the widest selections of professional-grade labels and printing consumables in Canada—from custom thermal transfer labels and weatherproof vinyl labels to laser sheet labels and blank inkjet labels designed for maximum clarity and endurance. Whether you need industrial-grade solutions or affordable blank inkjet labels for daily operations, we help businesses achieve consistent, professional results every time.

We also carry ink cartridges and label media compatible with leading printers such as Epson, ensuring you get the most from your equipment. And if you’re looking for high-performance alternatives, our range of Afinia, Primera Technology, and VIPColor printers deliver outstanding quality and durability for commercial use.

Poor label quality doesn’t just affect appearance—it can cost your business time, money, and customer trust. Don’t wait for smudges, fading, or peeling to damage your reputation. Order durable, professional-grade labels from DuraFast Label Company today and safeguard your brand from the hidden costs of label failure.