The Difference Between Thermal Transfer and Direct Thermal Labels

28th Oct 2025

Label printing plays an essential role in every industry—from retail and logistics to healthcare and manufacturing. Yet, choosing between direct thermal labels for sale and thermal transfer labels often confuses many business owners. Each printing method has unique characteristics, advantages, and best-use scenarios that directly impact labelling quality, durability, and long-term cost efficiency. Understanding these differences helps organizations make informed choices about their labelling setup, ensuring every print meets operational and professional standards.

Understanding Direct Thermal Printing

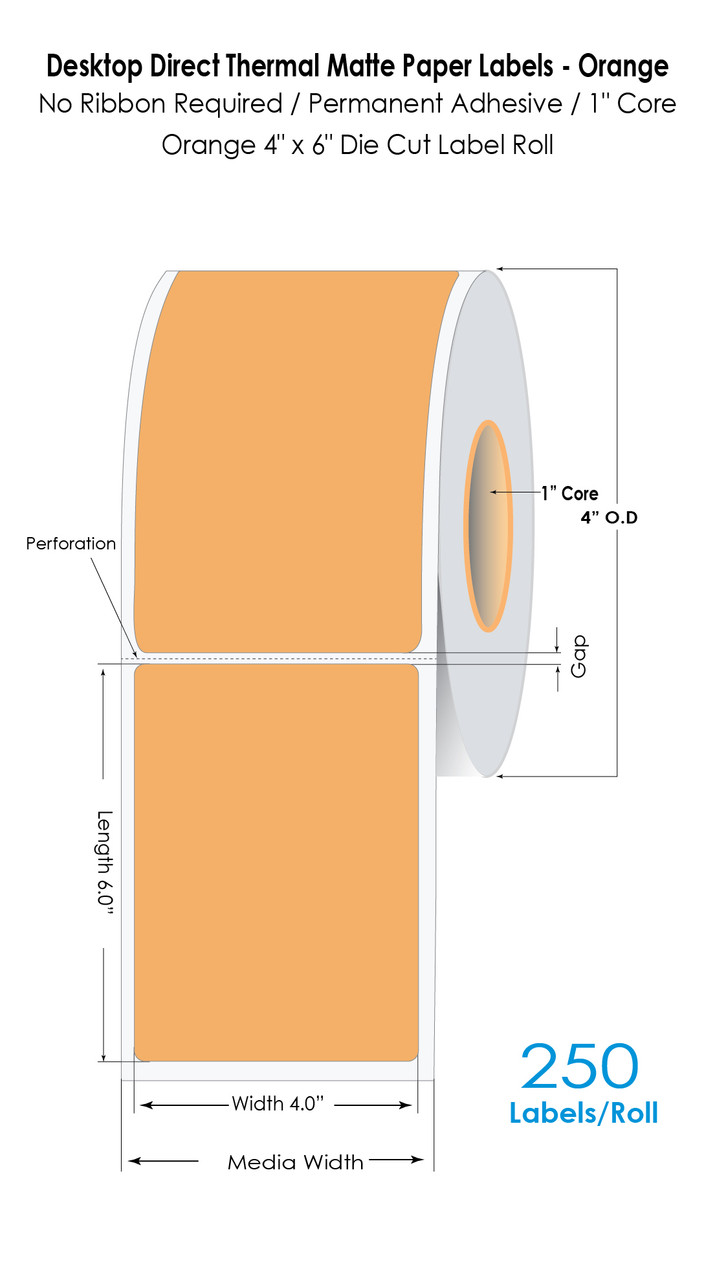

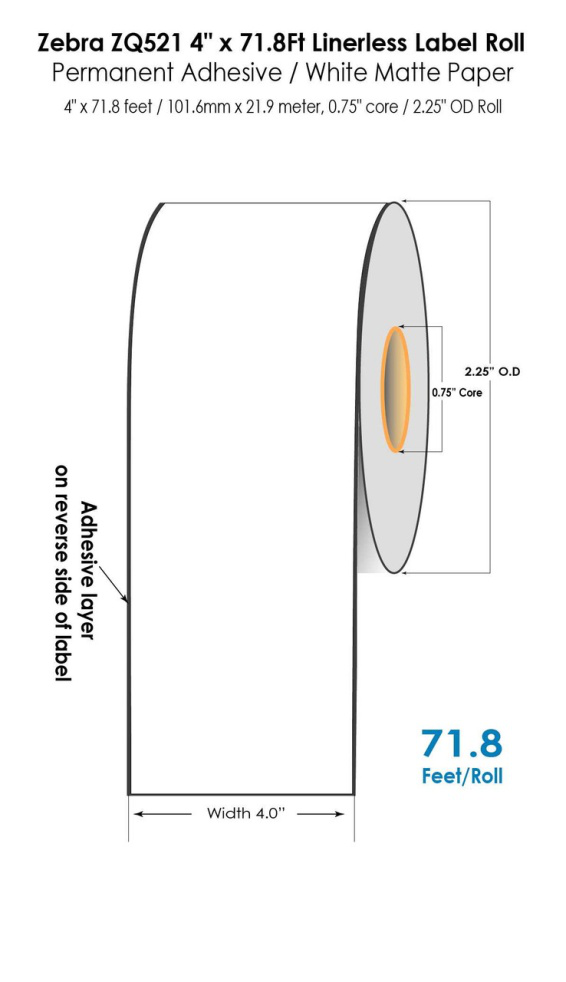

Direct thermal printing is one of the simplest and most efficient labelling methods available today. Instead of using ribbons, ink, or toner, this method relies on heat-sensitive paper that reacts when it passes under a heated printhead. The result is a sharp, clean, and smudge-free image created by the heat itself. Because it eliminates the need for ink or ribbons, it’s often used in environments where convenience, speed, and minimal maintenance are key priorities.

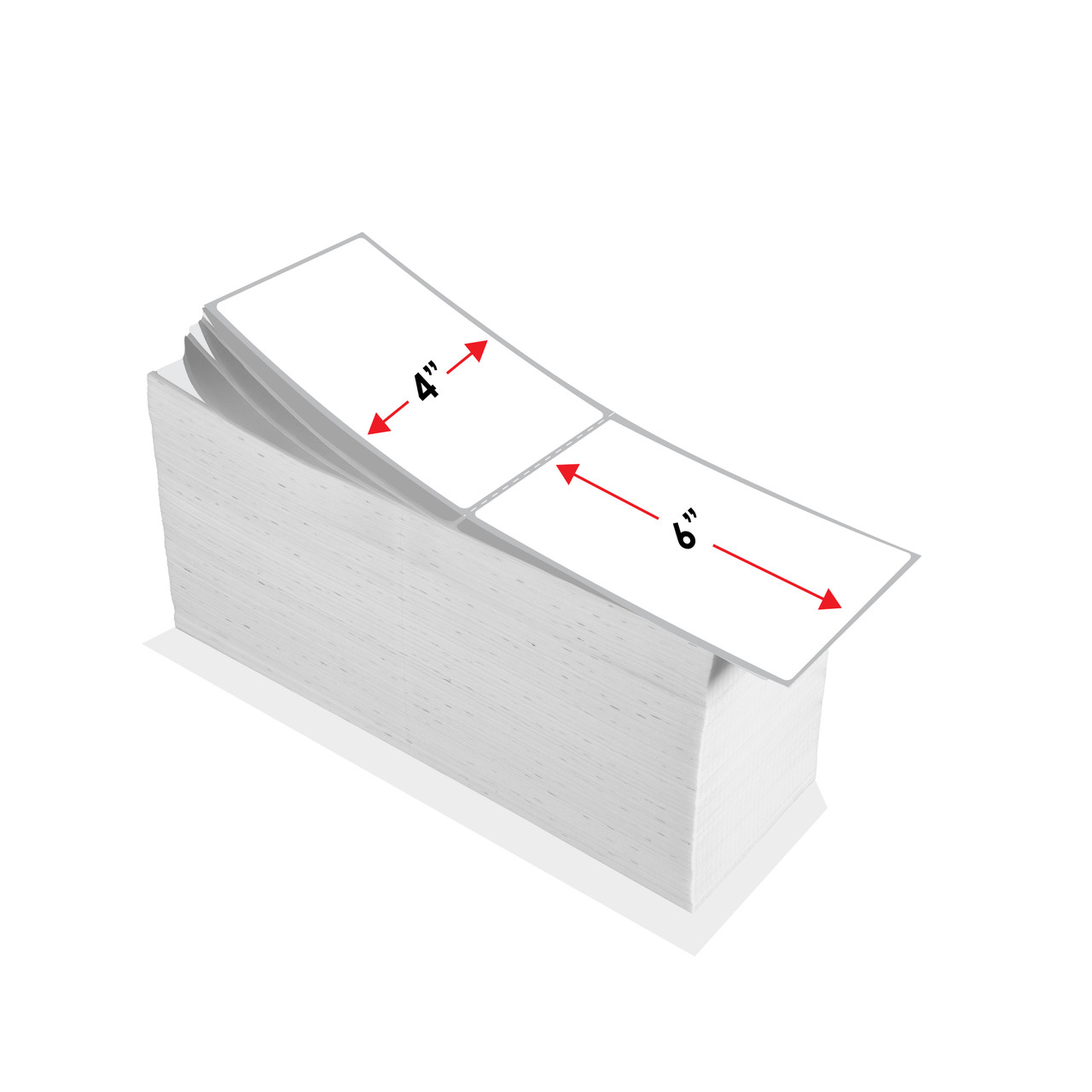

This technology is ideal for printing labels that are meant for short-term use—such as shipping labels, name tags, receipts, and barcode labels. In warehouse and retail operations, this means fewer consumables, faster label changes, and reduced operating costs. Businesses often pair this technology with thermal label printers for simple, fast setup and consistent output across departments.

However, direct thermal labels are not designed for long-term exposure to heat, light, or moisture. Over time, the print may fade, making them unsuitable for labelling items that require lasting readability, such as products in outdoor or industrial environments.

Key Advantages of Direct Thermal Labels

One of the strongest advantages of direct thermal printing lies in its simplicity. Since there are no ribbons or cartridges, operators experience fewer mechanical issues, which translates into minimal downtime. Businesses appreciate this efficiency in fast-paced environments where labels are produced in high volumes.

Direct thermal printing also offers outstanding cost-effectiveness. With fewer consumables to purchase, it’s a preferred choice for organizations looking to reduce supply costs while maintaining professional presentation. Additionally, direct thermal printers tend to have a smaller footprint and simpler design, allowing users to fit them easily into compact workstations or mobile setups.

Another benefit is speed. Direct thermal printers operate at high print speeds, which is particularly valuable in fulfillment centers, healthcare labs, and retail checkout points where time efficiency directly affects service quality. Many businesses use this technology alongside thermal pos receipt printers to maintain accuracy and consistency across transactions.

Limitations of Direct Thermal Labels

Despite their advantages, direct thermal labels do have some limitations. Since they depend on heat-sensitive materials, they are more vulnerable to environmental factors like sunlight, friction, and chemical exposure. This can cause fading or darkening, which compromises barcode readability or text clarity over time.

For businesses that require labels to remain intact for months or years, direct thermal labels may not be the best option. Long-term labelling applications—such as product identification, inventory storage, or asset tracking—demand a more resilient solution. In these cases, thermal transfer printing offers a more durable and reliable alternative.

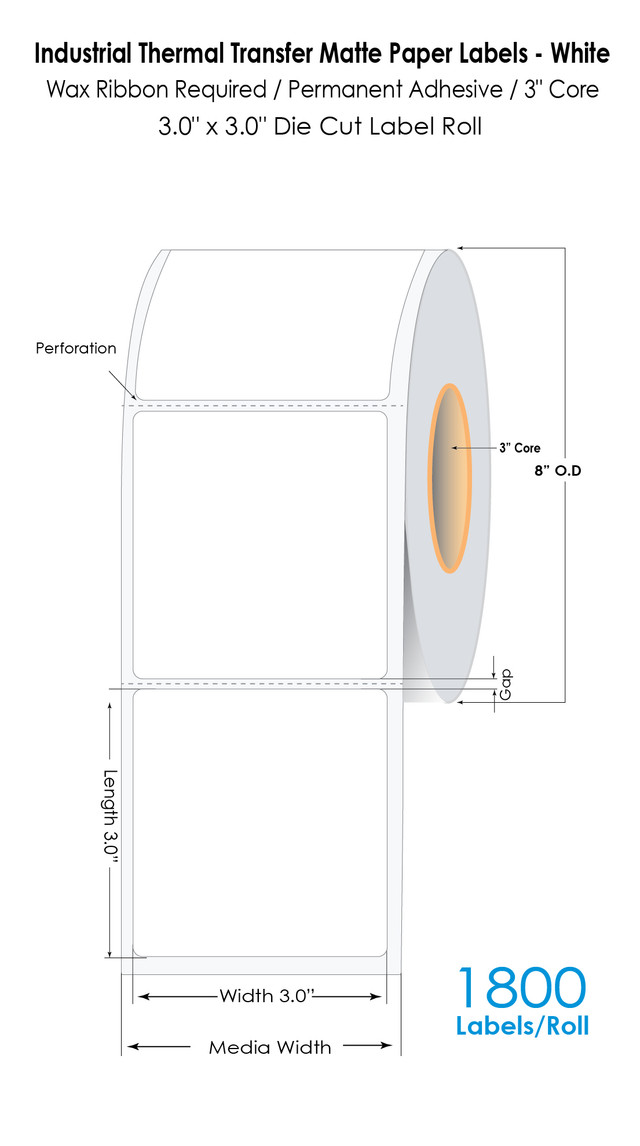

How Thermal Transfer Printing Works

Thermal transfer printing uses a ribbon coated with wax, resin, or a wax-resin blend. When heated, the ribbon’s coating transfers onto the label surface, creating a crisp, permanent image that can withstand time and harsh environments. This makes it suitable for applications that require labels to remain legible under challenging conditions.

Unlike direct thermal labels, thermal transfer labels can be printed on a wide range of materials, including paper, polyester, and polypropylene. This versatility is particularly important for industries where labels must resist chemicals, humidity, UV light, or physical abrasion. Many companies prefer to buy thermal transfer printers to produce long-lasting, weather-resistant labels for outdoor products, frozen goods, or industrial parts.

Benefits of Thermal Transfer Labels

Thermal transfer printing provides excellent print durability and versatility. Labels produced using this method can last for years without fading or smudging, even when exposed to sunlight or moisture. This makes them ideal for labelling assets, laboratory samples, electrical components, or hazardous materials that require extended traceability.

Another advantage is the ability to choose from a broad selection of ribbons and label materials. Users can customize label performance based on the environment in which it will be used—whether it’s a cold-storage facility, chemical lab, or outdoor distribution center. For instance, businesses often purchase custom thermal transfer labels to ensure precise compatibility with their products and industry standards.

Thermal transfer printing also allows for high-definition printing of logos, serial numbers, and barcodes. It’s a practical solution for manufacturers who value both quality and resilience. Furthermore, these labels maintain consistent print contrast, which improves barcode scanning accuracy in inventory management systems that use affordable barcode scanners.

Limitations of Thermal Transfer Printing

While thermal transfer printing delivers excellent durability, it involves more consumables and maintenance compared to direct thermal printing. The use of ribbons means more frequent replacements and a higher overall cost per print. Additionally, ribbons must be properly matched to the label material and application to ensure optimal results.

The need for regular calibration and occasional ribbon alignment may also slow down production slightly, particularly in smaller operations without dedicated printing staff. However, for businesses that prioritize label longevity and environmental resistance, these added steps are well worth the effort.

Comparing Label Longevity and Durability

When evaluating label longevity, thermal transfer labels outperform direct thermal labels in nearly every environment. The ink from the ribbon creates a permanent bond with the label surface, allowing the print to resist fading, moisture, and abrasions. This makes thermal transfer labels ideal for product identification and compliance labelling that requires years of durability.

Direct thermal labels, by contrast, are better suited for short-term tasks—like shipping, logistics, and temporary tracking. Because they don’t use ribbons, their images can degrade quickly when exposed to sunlight or heat. However, newer formulations such as premium topcoated direct thermal labels and non-topcoated direct thermal labels provide improved performance for moderate-term use, depending on the conditions.

Print Quality and Media Flexibility

Both technologies deliver excellent print quality when properly calibrated. Direct thermal printing produces sharp, high-contrast images suitable for scanning, though it is limited to black-and-white output. Thermal transfer printing, however, offers greater versatility with different media and colour ribbon options, supporting both monochrome and colour accents for branding or categorization.

Thermal transfer labels can also be printed on specialty materials like vinyl, polyester, and polypropylene, allowing for creative and durable applications. Businesses involved in product labelling or outdoor tagging may pair thermal transfer printers with vinyl labels for superior resilience.

Cost Considerations and Maintenance

Cost often becomes the deciding factor between these two printing methods. Direct thermal printing offers the lowest cost per print initially, given that it requires no ribbons or toners. It’s an attractive choice for small businesses, startups, and high-volume shipping operations that prioritize efficiency over longevity.

Thermal transfer printing, while more expensive in terms of consumables, offers lower long-term costs for industries where reprinting faded labels would be costly or time-consuming. The decision ultimately depends on the label’s expected lifespan and the environmental conditions it must endure.

Maintenance also varies. Direct thermal printers are easier to maintain since they have fewer moving parts and consumables. Thermal transfer printers require ribbon replacement and periodic cleaning, but their components generally last longer due to less wear on the printhead.

Choosing the Right Label Type for Your Business

Selecting between thermal transfer and direct thermal labels depends on the specific goals of the business. For instance, a shipping company handling fast-moving inventory might benefit from direct thermal labels due to their simplicity and cost-effectiveness. In contrast, a chemical manufacturer labelling containers for long-term storage would rely on thermal transfer printing for its durability.

Industries such as healthcare, manufacturing, logistics, and retail often use both methods strategically—employing direct thermal for short-term tracking and thermal transfer for asset labelling and compliance tags. Many organizations also use Bartender label software or Nicelabel software to design and manage templates compatible with either printing method, streamlining their operations.

Get Reliable Labelling Solutions That Last

Understanding the difference between thermal transfer and direct thermal labels helps businesses make better choices about printing efficiency, cost, and label longevity. While direct thermal labels offer simplicity and cost savings, thermal transfer printing delivers unmatched durability for demanding environments. Both technologies serve vital roles in ensuring smooth, accurate, and professional labelling workflows.

For businesses looking to upgrade or restock, DuraFast Label Company provides premium labelling solutions in Canada designed for reliability and performance. Whether you need direct thermal labels, thermal transfer labels, or affordable blank inkjet labels, the right products can help your operations run efficiently while maintaining top-quality output. Contact us today to find labelling solutions that match your business goals and deliver dependable results every time.