How to Track Products More Efficiently with Barcode Labels

15th Dec 2025

In today’s fast-moving supply chains, traceability is more than just a convenience — it’s a competitive necessity. Every manufacturer, retailer, and distributor needs an efficient way to identify, trace, and verify products across their entire journey from origin to delivery. That’s where barcode labeling comes in.

Barcodes are simple, affordable, and incredibly effective at linking the physical and digital worlds. With a single scan, businesses can retrieve real-time data about product details, storage conditions, and movement through the supply chain. But to get consistent, accurate results, companies must pair the right labels, printers, and materials.

At DuraFast Label Company, we’ve helped countless businesses optimize traceability using advanced barcode labeling systems. From thermal transfer printers to industrial-grade label materials, our expertise ensures every label is crisp, durable, and scannable under any condition.

Whether you’re managing warehouse stock or pharmaceutical packaging, the right combination of media and printer technology can completely transform your operation. Businesses in Canada looking for reliable, high-performance thermal barcode printers online will find solutions designed for longevity, clarity, and compliance.

Why Product Tracking Matters in Modern Supply Chains

Every link in today’s supply chain depends on visibility. Without clear, standardized labeling, products become harder to manage, and errors multiply. Barcode labeling ensures every component, carton, or pallet can be instantly identified — reducing confusion, loss, and waste.

The Business Value of Barcode Tracking

- Efficiency: Speeds up inventory management by replacing manual entries with automated scanning.

- Accuracy: Reduces data entry errors that cause costly mistakes.

- Compliance: Helps businesses meet industry regulations and traceability standards like GS1.

- Accountability: Ensures transparency from suppliers to retailers.

With the growing demand for supply chain traceability — especially in sectors like healthcare, food, and manufacturing — reliable barcode labeling has become an operational cornerstone. When your labels perform well, your entire business runs smoothly.

How Barcode Labels Improve Traceability

Barcodes are the silent workhorses of the global economy. Each one holds unique data — such as serial numbers, expiration dates, and origin codes — allowing products to be tracked across multiple systems.

1. Linking the Physical and Digital Worlds

When a product receives a barcode, it becomes digitally traceable. Each scan updates central databases in real time, allowing warehouse managers or retailers to monitor stock movements instantly.

2. Improving Recall Efficiency

If a recall occurs, barcode tracking ensures you can isolate affected products without disrupting your entire inventory. This precision minimizes financial losses and strengthens consumer trust.

3. Simplifying Compliance

In regulated industries like pharmaceuticals or chemicals, barcodes support global standards like GS1 and BS5609. These formats guarantee consistent labeling across the supply chain. DuraFast provides labels such as Epson GP-C831 BS5609 Chemical Labels, which meet maritime durability standards required for chemical exports.

By pairing accurate label printing with robust materials, companies achieve seamless compliance and full supply chain transparency.

Types of Barcode Labels and Printing Options

The success of any barcode system depends on choosing the right label type and printing method. Two primary technologies dominate the market: direct thermal and thermal transfer printing.

Direct Thermal Labels

These labels use heat-sensitive coatings to create images directly on the label surface. They’re cost-effective and ideal for short-term uses like shipping labels or receipts. However, they can fade when exposed to light, heat, or friction.

Thermal Transfer Labels

For long-term durability, thermal transfer printing is superior. It uses a ribbon that melts ink onto the label, producing fade-resistant, high-contrast images suitable for industrial environments.

Businesses often pair these printers with materials such as:

- GP-C831 High Gloss Paper Labelsfor professional packaging.

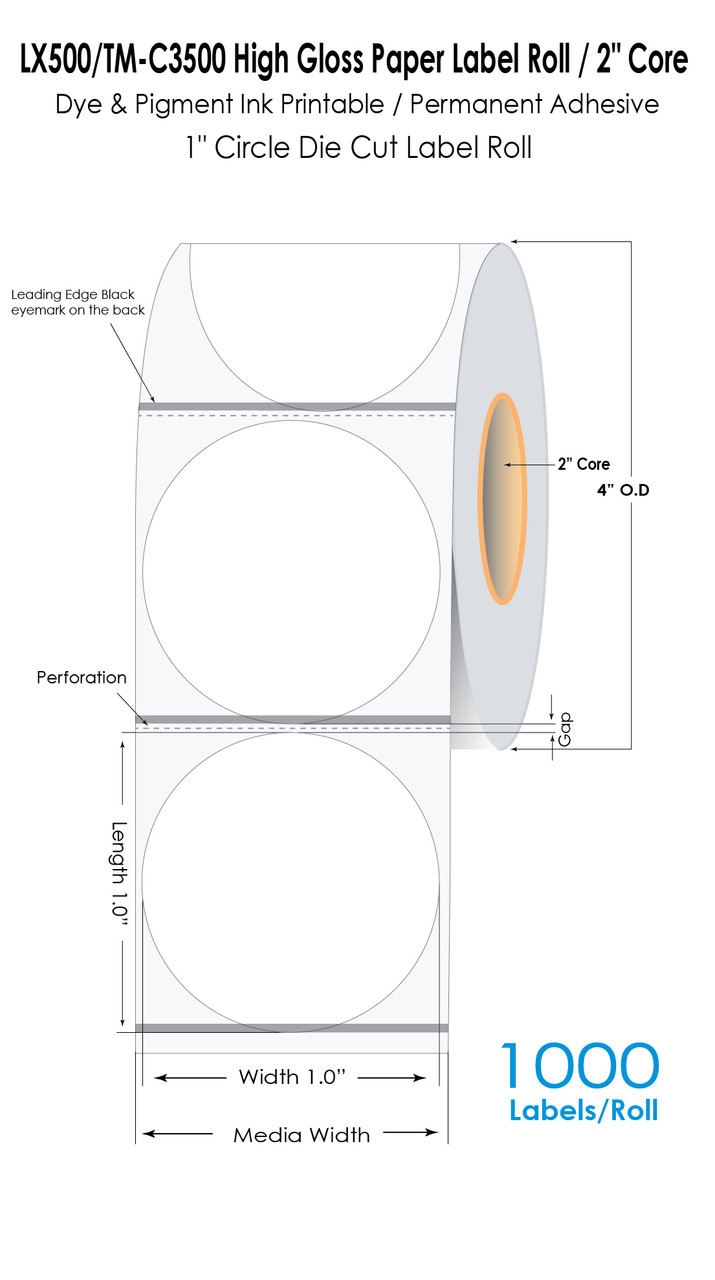

- Primera LX500 High Gloss Labelsfor crisp, detailed prints ideal for retail or branded products.

Each material serves specific needs. DuraFast’s experts help clients select the correct combination of label and ribbon for flawless, high-speed printing.

Best Printers for Barcode Labeling

The foundation of accurate labeling is a reliable printer. A low-quality printer can produce inconsistent barcodes that scanners struggle to read, leading to downtime and inefficiency.

One of the most dependable choices on the market is the GoDEX G530 4” Thermal Transfer Barcode Printer (300 DPI). This versatile machine delivers high-resolution prints suitable for both paper and synthetic labels.

Key Advantages of Industrial-Grade Printers

- Precision: Every barcode line and number is clean and legible.

- Durability: Designed to operate in industrial or warehouse settings.

- Flexibility: Compatible with a wide range of label sizes and materials.

- Connectivity: Works seamlessly with networked ERP and labeling systems.

By investing in robust hardware, businesses ensure consistency — every barcode printed today will still be readable months or years down the line.

Choosing the Right Label Material for Your Products

Barcode label performance is highly dependent on the material used. Paper, synthetic, and specialty substrates each have strengths based on their environment and purpose.

Paper Labels

Affordable and easy to print, paper labels are suitable for retail, shipping, and inventory use. However, they’re not recommended for high-humidity or outdoor settings.

Synthetic Labels

Made from polypropylene, polyester, or vinyl, synthetic labels are waterproof, tear-resistant, and designed for harsh conditions. They’re ideal for industrial, automotive, and outdoor applications.

The Epson GP-C831 High Gloss Labels mentioned earlier, for example, provide a smooth surface for vibrant, scannable printing while maintaining resistance to moisture and abrasion.

Specialty Labels

For specialized uses like chemical drums or asset tagging, labels such as Epson BS5609 Chemical Labels are designed to remain intact under extreme conditions — including saltwater immersion and UV exposure.

Selecting the right media ensures your barcodes remain readable, regardless of where your products go.

Maintaining Barcode Quality and Readability

Barcodes are only as good as their readability. Even a perfectly printed code can become useless if it smudges, fades, or is applied unevenly.

Tips for Long-Lasting Barcode Quality

- Keep Contrast High: Use dark ink on a light background for optimal scanner performance.

- Store Labels Properly: Humidity and dust can affect adhesive and print quality.

- Use Compatible Ribbons: Match wax, wax/resin, or resin ribbons based on the label material.

- Regular Maintenance: Clean the printer’s printhead regularly to prevent residue buildup.

- Avoid Overexposure: Shield labels from prolonged sunlight or high heat.

At DuraFast Label Company, we recommend pairing labels with high-quality thermal label printers for consistent output and fewer reprints.

Integration with Warehouse and ERP Systems

Modern labeling goes far beyond printing. Barcode systems now integrate seamlessly with enterprise resource planning (ERP) software, enabling automatic label generation and real-time data updates.

Software platforms such as NiceLabel software allow users to design, manage, and print labels directly from centralized databases. This ensures every label carries the correct information without manual data entry.

Integrating printing with ERP systems reduces human error, improves data consistency, and speeds up production — creating a truly automated labeling workflow.

Real-World Applications

Retail and E-Commerce

Barcode labels streamline product scanning, stock management, and checkout operations. They help retailers maintain up-to-date pricing and track sales trends efficiently.

Logistics and Warehousing

Shipping and pallet labels enable instant identification of goods during transport. Durable, scannable barcodes minimize shipping delays and improve inventory control.

Food and Beverage

Traceability is crucial for food safety. Barcodes provide full visibility into product origin, manufacturing date, and expiration, ensuring regulatory compliance.

Pharmaceuticals and Healthcare

Barcode labeling ensures patient safety by verifying medication accuracy and preventing counterfeiting. Compliance with healthcare labeling standards is critical for trust and efficiency.

Each of these sectors relies on barcode precision — and DuraFast Label Company provides the materials and printers to make that precision possible.

The Future of Product Tracking

As supply chains grow more complex, barcode technology continues to evolve. Hybrid solutions are emerging that combine barcodes with RFID or QR codes, enabling both human-readable and wireless data capture.

In the near future, we’ll see even greater automation, where smart printers generate barcodes directly from cloud-based systems. Sustainability will also play a larger role, with eco-friendly label materials replacing petroleum-based substrates.

No matter how labeling technology evolves, accuracy and consistency will remain paramount — and DuraFast is at the forefront of helping businesses stay ahead.

Smarter Tracking Starts with Quality Labels

Barcodes are the foundation of traceability — but behind every clear scan is a reliable printer, quality label, and expert support system.

At DuraFast Label Company, we help businesses of all sizes in Canada implement efficient, compliant labeling systems that keep their operations running smoothly. Whether you need high-volume production or specialized labeling for chemical compliance, our solutions ensure precision and performance.

For the most dependable results, we recommend combining high-quality thermal label printers, custom thermal transfer labels, and thermal barcode printers online for a comprehensive labeling solution that scales with your business.

Ready to improve traceability, accuracy, and compliance in your operation? Contact DuraFast Label Company today to get expert guidance and industry-leading labeling products built for efficiency.