How Thermal Transfer Labels Help Your Products Last Longer

16th Dec 2025

In product manufacturing, labeling is more than decoration—it’s communication. Every barcode, safety instruction, and compliance symbol represents traceability and trust. For businesses whose products travel through warehouses, shipping containers, or outdoor environments, those labels must endure months or years without fading.

That’s where thermal transfer labels for sale stand apart. They combine industrial durability with crisp print quality, producing results that withstand the conditions that ruin lesser labels.

At DuraFast Label Company, we’ve seen firsthand how the right labeling system prevents downtime, reduces waste, and keeps compliance documentation intact. This guide explains what thermal transfer printing is, how it works, and why it’s the gold standard for long-term product labeling.

Understanding Thermal Transfer Printing

Thermal transfer printing uses heat to bond a ribbon’s ink directly onto a label surface. Unlike direct thermal printers—which burn images onto heat-sensitive paper—thermal transfer technology creates a permanent mark by melting pigment from the ribbon onto the label substrate.

Key Components of a Thermal Transfer System

- Printhead: Applies heat in precise patterns to form text or barcodes.

- Ribbon: A film coated with wax, resin, or a combination of both.

- Label Media: Paper, polyester, vinyl, or polypropylene designed to accept melted ink.

Because the ink fuses into the label material, the image is resistant to water, abrasion, and UV exposure. It’s this physical transfer that makes thermal transfer printing ideal for industrial, chemical, and outdoor labeling.

Why Durability Matters in Labeling

Labels travel where your products go: dusty warehouses, refrigerated trucks, construction sites, and factory floors. A label that fades or peels can interrupt automated scanning, delay shipments, or violate regulatory standards.

Thermal transfer labels maintain readability far longer than direct thermal alternatives. Their resistance to fading, smudging, and scratching ensures that every barcode, batch number, and safety warning remains intact across the product’s entire lifecycle.

Durability isn’t just about surviving the environment—it’s about maintaining professionalism and compliance. When your labels still look sharp months later, they tell customers and inspectors that quality control matters to you.

Comparing Labeling Methods

Choosing between thermal transfer, direct thermal, and inkjet printing depends on how long you need labels to last.

|

Printing Method |

Durability |

Color Capability |

Typical Uses |

|

Direct Thermal |

Short-term (fades in heat/light) |

Monochrome |

Shipping labels, receipts |

|

Inkjet |

Medium-term (colorful, water-resistant if pigment-based) |

Full color |

Retail packaging, branding |

|

Thermal Transfer |

Long-term (resists UV, moisture, chemicals) |

Monochrome |

Industrial, asset, compliance labeling |

If your labels must survive years of exposure or rough handling, thermal transfer technology is the clear winner.

Choosing the Right Label Materials

Your label’s longevity depends heavily on its material. DuraFast supplies a variety of options to match different industries and environments.

Semi-Gloss Paper Labels

For general product labeling, the 3" × 2" Semi-Gloss Pre-Printed Thermal Transfer Labels combine professional appearance with affordability. They accept crisp thermal transfer images and are suitable for indoor use or light handling.

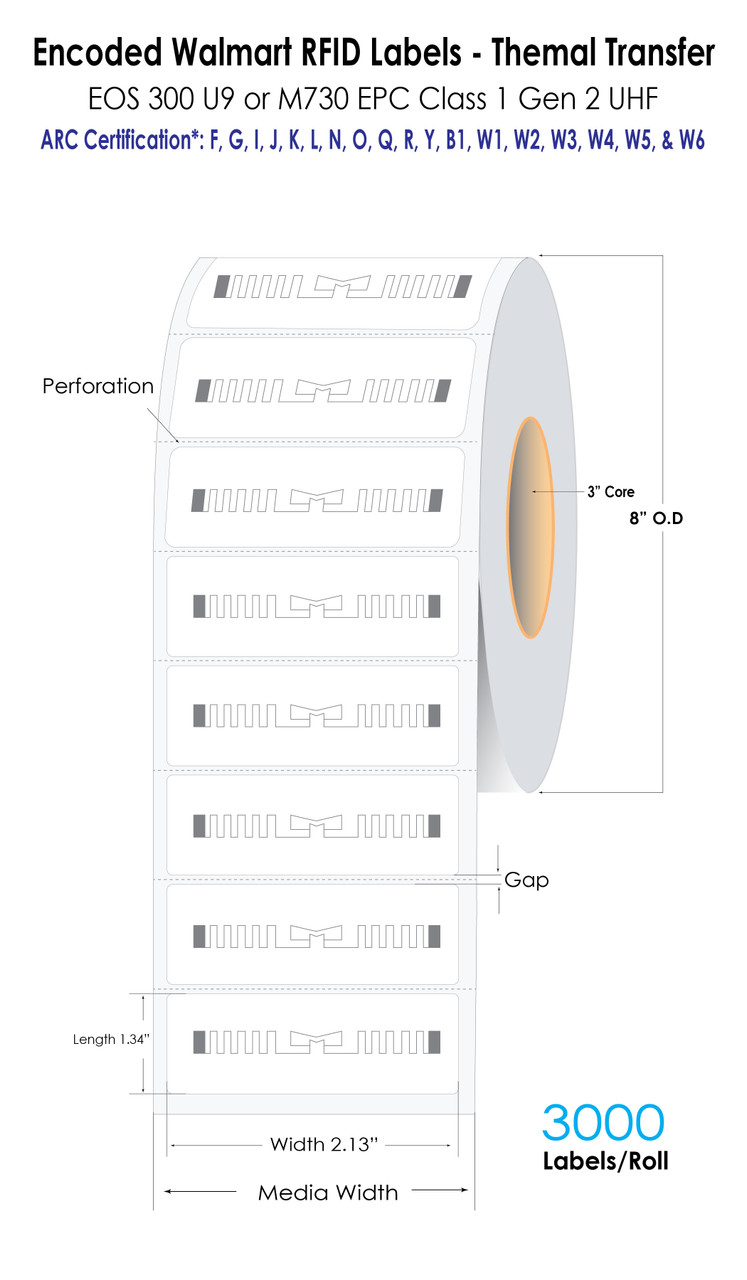

RFID-Enabled Thermal Transfer Labels

For inventory management, the Walmart Encoded RFID Labels merge rugged durability with smart tracking. They’re ideal for logistics, asset management, and compliance with major retailer requirements.

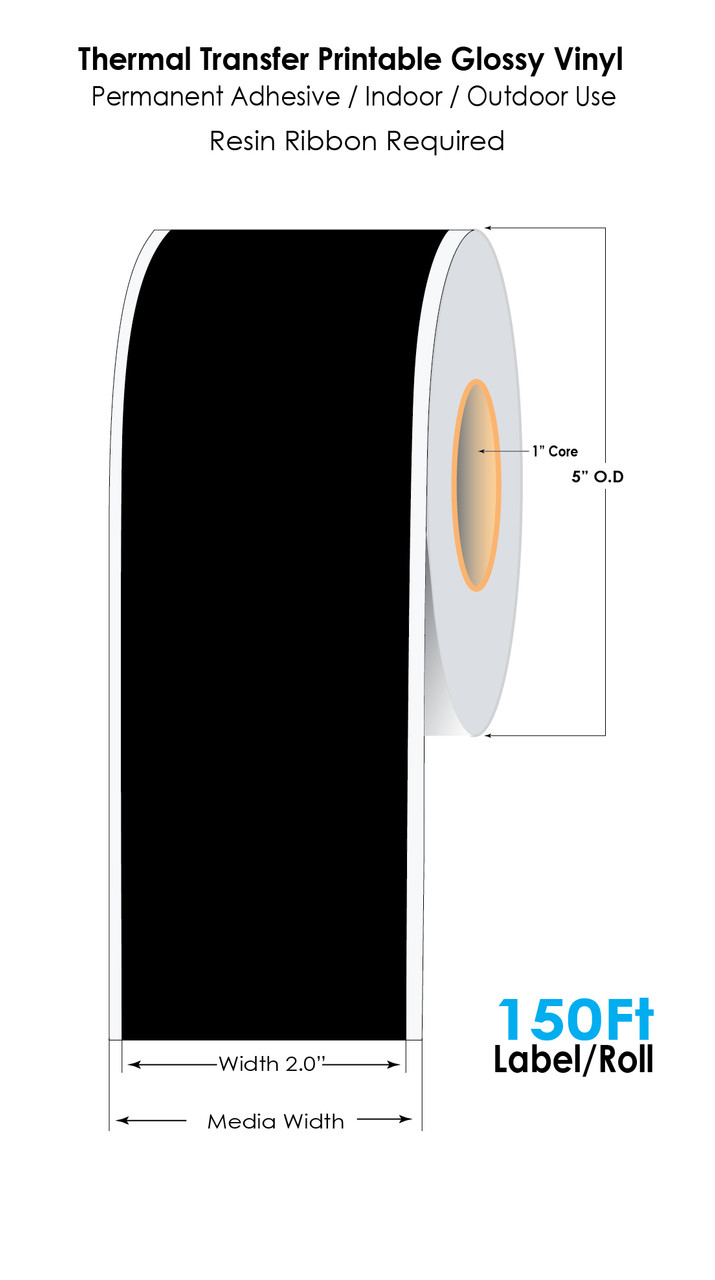

Vinyl Labels for Extreme Environments

When products face moisture, solvents, or mechanical stress, vinyl is unbeatable. The Black Glossy Vinyl Label Tape Roll and Clear Glossy Vinyl Tape Roll deliver flexibility and weather resistance, making them perfect for outdoor or chemical applications.

Each of these materials pairs with different ribbon types—choosing the right combination ensures sharp, durable results.

Ribbon Selection: The Unsung Hero of Durability

The ribbon determines how ink bonds with the label. There are three main categories, each serving different needs.

- Wax Ribbons:

Economical and suited for paper labels used indoors. They’re easy to print but offer limited abrasion resistance. - Wax/Resin Ribbons:

Blend flexibility and durability—ideal for coated papers or synthetics where moderate resistance is needed. - Resin Ribbons:

Premium ribbons that create ultra-durable prints resistant to chemicals, UV light, and high temperatures. Perfect for outdoor or industrial labels.

Using the wrong ribbon can lead to smudging or incomplete transfer. At DuraFast Label Company, we help clients pair ribbon and label formulations scientifically to achieve maximum longevity and performance.

Printer Calibration and Maintenance Tips

A great label system depends on consistent printer care. To maintain image quality:

- Clean the Printhead Regularly: Dust or adhesive residue can block heat transfer and cause missing lines.

- Store Ribbons Properly: Heat and humidity degrade ribbon coatings.

- Set Correct Heat Levels: Too much heat can melt ink excessively; too little causes light prints.

- Use Genuine Supplies: OEM ribbons and labels are engineered for optimal printhead contact and longer life.

Preventive maintenance extends printhead lifespan and ensures every barcode scans perfectly.

Thermal Transfer Labels in Action

1. Manufacturing and Asset Tracking

Industrial plants rely on thermal transfer labels to mark machinery, components, and tools. These labels remain legible even after exposure to lubricants and vibration.

2. Electronics and Electrical Equipment

Thermal transfer labels are common on wiring harnesses, circuit boards, and electrical panels. Their heat resistance prevents melting or fading near high-temperature components.

3. Chemical Packaging

Chemical drums must comply with GHS (Globally Harmonized System) labeling. Resin-printed polyester labels resist solvents and acids while retaining barcode integrity.

4. Healthcare and Laboratories

Specimen and asset labels in laboratories must survive refrigeration and sterilization. Thermal transfer printing provides the permanence required for patient safety and traceability.

5. Logistics and Warehousing

In warehouses, products move across climates—from humid docks to freezing trucks. Thermal transfer barcodes remain scannable through it all.

Why Businesses Prefer Thermal Transfer Systems

1. Longevity and Reliability

Thermal transfer prints can last five to ten years under typical conditions, compared to a few months for direct thermal.

2. Versatility

The same printer can handle paper, synthetic, or specialty materials with simple ribbon changes.

3. Compliance Confidence

Many regulatory standards—from OSHA safety labels to UL certification marks—require durable, permanent labeling achievable only with thermal transfer.

4. Cost-Effectiveness Over Time

While the upfront investment in ribbons seems higher, the reduced waste and reprinting costs make it more economical long-term.

Integrating Thermal Transfer Printing into Your Workflow

DuraFast helps companies integrate labeling seamlessly into production lines and ERP systems. With automation software, printers can pull variable data—like batch codes or serial numbers—directly from databases, eliminating manual entry errors.

Integration also allows mixed-media printing, where branding and compliance data appear on the same label without sacrificing speed or quality.

We offer technical support for setup, calibration, and workflow optimization to ensure your investment pays off from day one.

Sustainability and Eco-Friendly Considerations

Durable labeling is inherently sustainable. Longer-lasting prints mean fewer replacements and less material waste.

Modern ribbons and substrates are evolving to include recyclable polyester films and solvent-free coatings. DuraFast continually tests new eco-conscious materials to ensure they meet the same durability standards customers expect.

By choosing high-performance materials once, businesses can minimize their environmental footprint over the years of production.

Common Mistakes to Avoid

Even robust systems can fail from small oversights:

- Using Incompatible Ribbons: A wax ribbon on vinyl media won’t last outdoors.

- Skipping Printer Cleaning: Residue burns onto the printhead and distorts barcodes.

- Incorrect Storage: Labels exposed to humidity lose adhesive strength.

- Overheating: Excess print darkness causes bleeding and ribbon wrinkles.

- Neglecting Testing: Always test labels in their actual environment before full production.

Avoiding these mistakes extends both label lifespan and printer reliability.

The Future of Thermal Transfer Labeling

Advancements in thermal transfer technology continue to redefine industrial labeling. Near-edge printheads enable faster printing on flexible packaging, while smart sensors optimize ribbon usage to reduce waste.

Hybrid labeling systems now integrate RFID or QR codes into traditional prints, merging physical durability with digital traceability. DuraFast stays ahead of these innovations, ensuring our customers benefit from the latest printing science.

In the coming years, expect thermal transfer solutions that are faster, smarter, and more sustainable—without compromising on endurance.

Partnering with the Experts

Labeling may seem simple, but every industry presents unique environmental and compliance challenges. Partnering with an experienced supplier ensures you’re equipped with materials, printers, and ribbons optimized for your needs.

At DuraFast Label Company, we take pride in guiding businesses in Canada through every step—from printer selection to label design and maintenance schedules. Our mission is to help clients print with confidence and precision, no matter how demanding their conditions.

Long-Lasting Labels for Long-Lasting Products

In today’s competitive markets, product integrity extends to labeling integrity. A label that endures reinforces your brand’s reliability, ensures regulatory compliance, and saves time and cost over the product’s life.

That’s why DuraFast recommends thermal transfer labels for sale as the foundation of any industrial or commercial labeling system. Combined with high-quality thermal label printers and custom thermal transfer labels, they deliver unmatched clarity, resilience, and consistency.

If you’re ready to upgrade your labeling for performance that lasts as long as your products do, contact DuraFast Label Company today. Our experts will help you choose the right materials and printers to build a labeling solution engineered for longevity.