Best Practices for Using Vinyl Labels in Industrial and Outdoor Settings

22nd Dec 2025

Industrial environments are harsh — surfaces are uneven, exposure to chemicals is routine, and weather conditions fluctuate between extreme heat, cold, moisture, and UV radiation. In such conditions, standard paper or synthetic labels simply can’t endure. That’s why companies across manufacturing, automotive, logistics, and energy sectors increasingly rely on vinyl labels in Canada and worldwide for long-term, high-performance identification.

Vinyl labeling technology has evolved far beyond simple stickers. Modern vinyl materials, when paired with compatible thermal-transfer printers and resin ribbons, can last for years outdoors without peeling, fading, or smearing. These labels not only survive exposure but also remain legible — ensuring safety warnings, part numbers, or compliance information stay intact.

At DuraFast Label Company, we’ve spent years equipping industrial facilities with the tools and materials to print resilient vinyl labels that meet stringent safety and durability requirements. In this guide, we’ll cover the science behind vinyl durability, environmental performance, and expert tips for maximizing label lifespan in tough environments.

Why Vinyl Labels Matter in Demanding Environments

Industrial and outdoor operations depend on labeling for traceability, compliance, and safety. Labels identify electrical components, mark pipes, tag machinery, and help workers quickly recognize hazards. When those labels fail, the consequences can range from production delays to safety violations.

Vinyl has emerged as the material of choice for several reasons — flexibility, chemical resistance, and print longevity. Unlike paper or polyester, vinyl can conform to curved or uneven surfaces while retaining adhesion and legibility. This flexibility is critical in environments where metal pipes, plastic drums, or automotive components need consistent, permanent identification.

Superior Resistance to Weather and Abrasion

Vinyl labels offer unmatched durability against the elements. They resist UV fading, moisture penetration, and surface abrasion, maintaining clarity for years. When printed with resin-based ribbons, the ink bonds deeply to the surface, creating a waterproof and solvent-resistant finish.

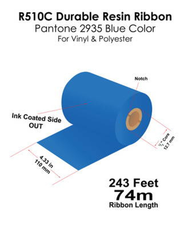

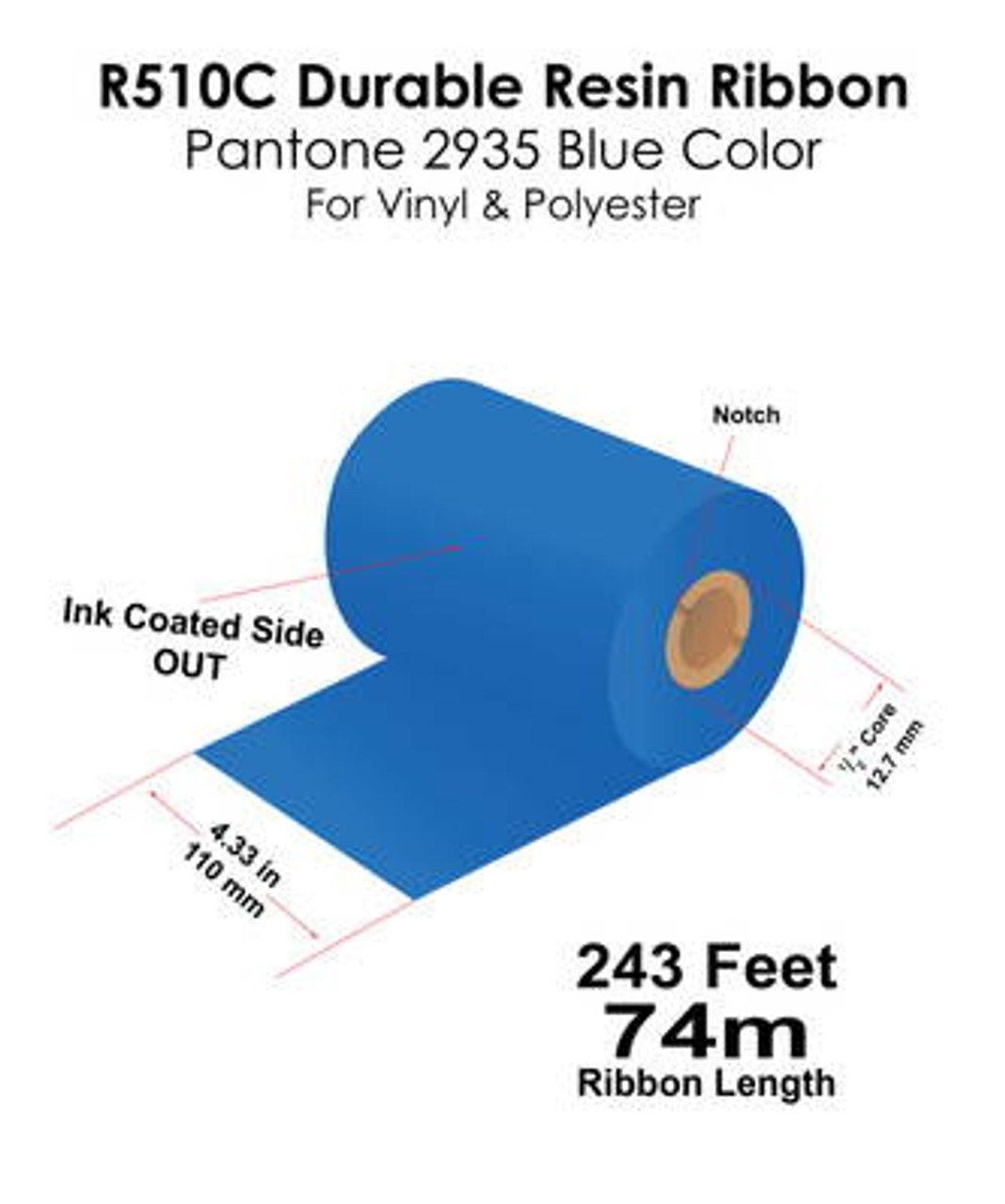

For instance, the VINYL 4.33 x 243 ft R510C Blue Durable Resin Ribbon CSO for Zebra, Brother TD4, GoDEX G330, and TSC Desktop Printers produces labels that withstand abrasion, oils, and chemicals common in automotive and manufacturing facilities. When combined with high-resolution thermal-transfer printing, it ensures precise barcodes and text that don’t degrade under stress.

Adhesion Across Extreme Surfaces

One of vinyl’s strengths is its ability to adhere to textured, rough, or curved surfaces. Industrial pipelines, painted machinery, or irregular components often challenge traditional adhesives. Vinyl labels solve this through flexible polymer compositions and pressure-sensitive backings engineered for high tack.

For instance, continuous vinyl tapes such as the Brother BMSLT202 2” x 150 ft White Continuous Vinyl Thermal Transfer Label Tape provide consistent coverage and dependable adhesion even on metal or PVC tubing.

Cost Efficiency Over Time

While vinyl labels may cost slightly more upfront than paper or polypropylene, their longevity delivers a lower total cost of ownership. Businesses save on replacement frequency, reprinting time, and compliance risks. This durability makes vinyl particularly attractive for asset management systems, outdoor signage, and labeling in automotive maintenance facilities.

Key Properties of Industrial-Grade Vinyl Labels

Understanding what makes vinyl effective begins with its composition. Industrial vinyl labels combine polyvinyl chloride (PVC) film with advanced adhesives and coatings that enhance print receptivity, flexibility, and protection.

1. Flexibility and Conformability

Vinyl’s pliable structure allows it to wrap around cylindrical or irregular surfaces without wrinkling. Unlike rigid materials such as polyester, vinyl stretches slightly under tension and conforms seamlessly — an advantage when labeling pipes, wires, or rounded containers.

Applications include:

- Electrical cable identification

- Hydraulic hoses and tubing labels

- Curved automotive components

- Drum and barrel labeling for chemicals

In high-motion environments, vinyl’s elasticity prevents cracking or peeling when surfaces expand, contract, or vibrate.

2. Chemical and Solvent Resistance

Industrial processes often expose labels to harsh chemicals — lubricants, fuels, degreasers, or cleaning agents. Standard inks can dissolve under such conditions, but vinyl with resin-based thermal-transfer printing resists these substances.

Resin inks melt into the vinyl surface during printing, forming a chemical bond that withstands ethanol, isopropyl alcohol, hydraulic fluids, and more. This chemical resistance ensures safety data, barcodes, and identification remain visible even in chemical-handling facilities or automotive repair shops.

A good match for these demanding applications is the MAX Letatwin LM-TU442L L-Tube 4.2 mm x 200 m Vinyl PVC Drum Roll, commonly used in electrical and instrumentation labeling. Its construction offers long-term chemical and UV resistance — perfect for wiring systems in plants or outdoor infrastructure.

3. UV and Temperature Tolerance

Outdoor and industrial labeling often means exposure to direct sunlight and fluctuating temperatures. Over time, UV light can break down polymers, causing fading or brittleness. To combat this, industrial vinyl labels are formulated with UV inhibitors and heat-stabilized additives that prolong elasticity and color retention.

High-quality vinyl labels perform reliably from –40 °C to +150 °C, depending on adhesive and ribbon selection. This makes them suitable for outdoor equipment, vehicle components, and temperature-controlled environments.

4. Printable Surface and Finish Options

Vinyl labels come in various finishes — matte, gloss, or satin — allowing customization for readability and appearance. Matte surfaces reduce glare for barcode scanning, while glossy labels enhance brand presentation and cleanability.

Thermal-transfer printable vinyl also accepts a wide range of colors, including safety hues like red, yellow, and blue. For example, colored vinyl options like the GoDEX GE330 4” 300 DPI Thermal Transfer Vinyl Tape Label Printer with Cutter (Yellow Tape Kit) provide flexibility for color-coding hazard categories or product batches.

5. Adhesive Strength and Longevity

Vinyl’s adhesive systems determine how well a label endures harsh surfaces and environments. Industrial variants use acrylic-based or rubber-based adhesives tailored for specific use cases:

- Acrylic adhesives offer strong initial tack and long-term resistance to UV and temperature fluctuations.

- Rubber-based adhesives deliver superior performance on rough or low-energy surfaces like powder coatings.

In heavy manufacturing or automotive plants, acrylic-based vinyl labels typically last five years or more, even under routine cleaning and exposure cycles.

6. Compatibility with Thermal-Transfer Printers

For optimal durability, vinyl labels must be printed using high-temperature, high-resolution printers equipped with resin ribbons. These systems fuse the ribbon’s pigment layer onto the vinyl’s surface, ensuring the text becomes part of the label rather than sitting atop it.

Printers like GoDEX, Brother, and SATO models — available from DuraFast Label Company — are engineered for this process, delivering sharp barcodes, logos, and safety icons even at industrial speeds. Proper calibration of heat, speed, and pressure ensures each label receives consistent pigment transfer, preventing smudging or incomplete prints.

Why Resin Ribbons Are Essential

Resin ribbons are the secret behind vinyl’s lasting performance. Their chemical structure creates strong, permanent bonds under heat, producing scratch-resistant and solvent-proof prints. Compared to wax or wax/resin blends, resin ribbons resist abrasion from tools, gloves, or chemical splashes.

For long-term outdoor signage or equipment tags, pairing vinyl labels with a resin ribbon such as the R510C Blue Durable Resin Ribbon ensures years of fade-free identification — even in marine, oil, and chemical environments.

Environmental Impact of Vinyl Labels

While vinyl is a synthetic material, advancements in manufacturing have made it more sustainable. Many suppliers, including DuraFast, now offer recyclable vinyl liners and solvent-free adhesives. These innovations reduce VOC emissions and landfill waste while maintaining industrial-grade strength.

By adopting vinyl labeling best practices, businesses can extend label lifespan, minimize waste from reprinting, and contribute to sustainable operations — an increasingly important factor for industrial clients pursuing ISO 14001 or ESG goals.

Applications of Vinyl Labels Across Industrial and Outdoor Sectors

Vinyl labels are the backbone of industrial identification systems — used wherever legibility, durability, and compliance intersect. Their resilience makes them indispensable across automotive, manufacturing, energy, and outdoor infrastructure sectors. Each application demands unique performance characteristics, from chemical resistance to high-temperature endurance.

Below, we explore how different industries utilize vinyl labels to solve specific challenges and why selecting the right media-printer combination is vital.

1. Automotive and Aerospace Manufacturing

In automotive and aerospace environments, labels face relentless heat, fluids, and movement. Components such as wiring harnesses, engine parts, or control panels require labeling that won’t peel, curl, or fade.

Vinyl labels provide that dependability — especially when printed using vinyl label printers in Canada equipped with resin ribbons. They remain legible under engine heat and vibration, ensuring critical safety and tracking information stays visible.

Automotive-grade vinyl labels often carry:

- Barcodes for component tracking.

- Compliance symbols (like CE or UL).

- Caution and maintenance instructions resistant to oil and grease.

Thermal-transfer systems like the GoDEX GE330 Thermal Transfer Vinyl Tape Label Printer are ideal for these tasks, producing precise, fade-resistant prints on heat-tolerant vinyl tapes.

2. Chemical and Laboratory Environments

Chemical storage and laboratory environments expose labels to harsh solvents and sterilization processes. Paper or polypropylene labels degrade quickly, risking safety violations.

Vinyl, however, withstands these chemicals and high temperatures, making it suitable for bottles, drums, vials, and lab equipment. With appropriate resin ribbons, labels remain smudge-free even after repeated contact with ethanol, acetone, and cleaning agents.

For chemical plants, continuous vinyl rolls like the Brother BMSLT202 2” x 150 ft White Vinyl Thermal Transfer Tape offer flexible labeling for irregular surfaces such as curved containers or coated metal drums.

3. Construction and Outdoor Infrastructure

Construction sites and outdoor utilities rely on vinyl for signage, electrical labeling, and pipe identification. In these scenarios, labels must survive UV exposure, temperature extremes, and moisture without delaminating.

Contractors and maintenance professionals use durable tapes and portable printers to label equipment and cabling on-site. Vinyl’s tear resistance and adhesive reliability ensure information remains visible for years, even under harsh sun or rain.

Laminated or clear-coated vinyl provides added defense against dust and UV radiation — vital for long-term outdoor durability.

4. Energy and Utilities

In power plants, renewable energy installations, and oil and gas facilities, vinyl labels play a crucial safety role. They identify electrical hazards, valve types, maintenance intervals, and equipment status.

Energy-sector labeling often requires compliance with ANSI Z535 or OSHA safety standards, which dictate color-coding and symbol visibility. Vinyl’s availability in multiple colors makes it perfect for such compliance labeling.

Labels can also withstand the vibration, oil mist, and extreme temperatures typical of mechanical or turbine environments. This is where high-end custom thermal transfer labels become essential, providing a tailored solution for long-term performance in specialized conditions.

5. Marine and Transportation

Marine and logistics environments expose labels to salt, humidity, and constant friction. Vinyl’s hydrophobic nature ensures adhesion even on damp or painted metal surfaces.

Boat manufacturers, shipping companies, and freight operators depend on vinyl labels for tracking, serial identification, and safety signage. Adhesives designed for marine use prevent peeling despite salt spray or mechanical wear.

Best Practices for Printing Vinyl Labels

Printing on vinyl requires precision — the material’s flexibility and heat sensitivity demand careful calibration to achieve optimal print density and bonding. To get flawless, professional results in industrial or outdoor applications, follow these expert techniques.

1. Choose the Right Printer and Ribbon Combination

Vinyl labeling’s success depends on your printing equipment. Choose thermal-transfer printers capable of fine-tuning temperature and speed, as excessive heat may warp vinyl.

For outdoor-rated prints, resin ribbons are mandatory. They create chemical and UV-resistant images that won’t smear or fade. Pair them with printers like:

- GoDEX GE330 — ideal for color-coded labeling and heat resistance.

- Brother TD4 or SATO industrial models — designed for high-precision production runs.

Using mismatched ribbons or subpar equipment may reduce print adhesion or cause ribbon breakage during long runs.

2. Optimize Printer Settings

Each printer offers different configurations for heat, pressure, and feed rate. Here are essential adjustments for vinyl:

- Lower speed settings to allow complete pigment transfer.

- Moderate heat levels to prevent material distortion.

- Increased pressure on textured or matte surfaces for stronger adhesion.

Before running large batches, print test strips to verify barcode legibility and line clarity under various lighting and temperature conditions.

3. Label Surface Preparation

Even the strongest adhesive fails on a dirty or oily surface. Before applying vinyl labels:

- Clean the surface using isopropyl alcohol.

- Allow it to dry completely.

- Avoid touching the adhesive side during application.

For textured materials like painted metal or plastic pipes, use firm pressure or a roller to eliminate air bubbles. This ensures uniform bonding and prevents early peeling.

4. Application Temperature and Environment

Adhesive performance depends on application temperature. Most industrial vinyl labels adhere best between 10°C and 40°C (50°F–104°F).

For cold surfaces, preheat slightly or use low-temperature adhesive formulations. Once applied, high-performance acrylic adhesives maintain grip from –40°C to +150°C, even outdoors.

5. Allow Proper Curing Time

Vinyl adhesives typically reach maximum bond strength after 24–48 hours. Avoid heavy cleaning, moisture, or abrasion during this curing period. This simple precaution ensures your labels stay firmly in place long-term.

Maintenance and Storage Tips for Vinyl Labels

Even the most durable labels require care to maintain performance during storage and application. Proper handling preserves adhesive strength and prevents curling or fading before use.

1. Storage Conditions

Store vinyl rolls in a cool, dry environment (18–24°C) with 40–60% relative humidity. Avoid direct sunlight and excessive stacking, as prolonged pressure can distort rolls.

Always keep rolls in their original packaging until needed. This protects the label surface and prevents dust accumulation, which can interfere with thermal transfer printing.

2. Shelf Life Management

Vinyl labels generally maintain optimal print and adhesion quality for up to two years when stored correctly. Older materials may lose flexibility or adhesion. Label inventory with “received” and “use by” dates to ensure consistency in large-scale operations.

3. Cleaning Printed Labels

When cleaning surfaces with applied vinyl labels, use mild detergents or isopropyl alcohol — avoid solvents like acetone or xylene unless you’re using resin-ribbon-printed labels specifically rated for such exposure.

For equipment exposed to dust or oil, occasional wiping prevents buildup and keeps labels legible for scanning or safety compliance.

4. Avoid Overlamination Errors

Some operations apply a clear laminate over vinyl labels for extra protection. While effective, incorrect lamination may trap air or moisture, creating cloudy spots or peeling edges.

To avoid this:

- Apply the laminate slowly with consistent pressure.

- Use a squeegee or applicator roller to remove trapped air.

- Ensure printed labels are fully cured before applying lamination.

5. Replacement and Lifecycle Tracking

Track label performance during maintenance inspections. Replace any labels that show signs of peeling, fading, or abrasion. Industrial software or handheld scanners can automate inspection logs, flagging labels nearing the end of their rated lifespan.

6. Proper Disposal and Sustainability

Although vinyl is non-biodegradable, it can be recycled when processed correctly. Partner with waste management services that handle PVC recycling or repurpose used liners. DuraFast also provides eco-friendly vinyl options using low-VOC adhesives and recyclable cores — helping you align operational durability with environmental responsibility.

Environmental Testing and Certification for Industrial Vinyl Labels

Industrial-grade labeling isn’t just about appearance — it’s about compliance. Many industries require labels to withstand extreme environments while meeting regulatory standards. Testing and certification ensure vinyl labels maintain integrity under heat, UV light, moisture, and chemical exposure.

1. UV and Weathering Tests

Outdoor labels face relentless sunlight that can cause fading or cracking over time. Accelerated weathering tests, such as ASTM G154, simulate months or years of UV exposure in a few weeks. High-performance vinyl passes these tests with minimal discoloration or loss of adhesion, confirming long-term durability for field equipment, vehicles, and signage.

2. Chemical Resistance Tests

Labels used in manufacturing, oil and gas, or laboratory environments undergo solvent and oil resistance testing. These tests evaluate print and adhesive performance after immersion in chemicals such as gasoline, ethanol, or lubricants. Resin-printed vinyl labels generally outperform alternatives, retaining legibility and adhesion even after repeated cleaning or exposure.

3. Temperature Cycling and Humidity Testing

Thermal shock and condensation can weaken adhesives or cause labels to bubble. Certified vinyl materials undergo temperature cycling — transitioning between –40°C and +150°C — to verify stability under sudden climate changes. Humidity resistance tests confirm the adhesive won’t lift or cloud even in tropical or refrigerated conditions.

4. Abrasion and Impact Testing

Industrial labels frequently endure contact with gloves, tools, or moving machinery. Durability assessments, such as the Taber Abrasion Test, measure how many cycles of friction a label can withstand before the print shows wear. High-quality vinyl printed with resin ribbons routinely passes these trials, making them ideal for high-traffic or high-handling environments.

These certifications assure manufacturers that their labeling system won’t fail in mission-critical conditions — protecting assets, ensuring safety, and maintaining compliance documentation.

Common Mistakes to Avoid When Using Vinyl Labels

Even with premium materials, simple oversights can undermine a labeling program. Here are common pitfalls and how to prevent them.

1. Ignoring Surface Compatibility

Not all surfaces are created equal. Applying vinyl labels to oily, dusty, or painted surfaces without cleaning leads to adhesion failure. Always perform a small adhesion test before committing to bulk applications.

2. Using the Wrong Ribbon Type

Wax or wax/resin ribbons are insufficient for industrial vinyl. They may produce readable prints initially, but degrade under heat, chemicals, or friction. Always pair vinyl labels with resin ribbons for permanent results.

3. Overlooking Environmental Fit

Labels used indoors differ drastically from those exposed to the sun or saltwater. Selecting materials based solely on price rather than application environment often results in early fading or peeling.

4. Skipping Calibration

Thermal-transfer printers must be calibrated for vinyl thickness and ribbon tension. Misalignment causes ribbon wrinkles, patchy prints, or wasted material. Regular calibration ensures consistent image density across long production runs.

5. Neglecting Preventive Maintenance

Dirty printheads are the silent killers of quality. Clean the printhead after every few rolls and inspect rollers for adhesive buildup. Scheduled maintenance maximizes printer lifespan and output consistency.

Avoiding these common missteps guarantees that your investment in durable vinyl labels delivers the long-term performance you expect.

Case Studies: Vinyl Labels in Real-World Industrial Settings

Case Study 1: Automotive Manufacturing

A major automotive parts supplier faced issues with barcode degradation during under-hood component assembly. Paper and polypropylene labels were peeling off due to heat and engine oil exposure.

Switching to high-tack vinyl labels printed with resin ribbons on GoDEX GE330 printers resolved the problem. Labels maintained adhesion and readability through heat cycles and chemical exposure, reducing reprints by 85% and saving thousands in labor.

Case Study 2: Oil and Gas Pipelines

An oil pipeline maintenance contractor required outdoor equipment tags capable of surviving extreme Canadian winters and constant UV exposure. Their previous laminated polyester labels cracked in sub-zero temperatures.

DuraFast recommended industrial vinyl labels in Canada paired with acrylic adhesives and resin ribbons. After 18 months of field use, all labels remained intact and readable, even under snow, rain, and direct sunlight — outperforming previous materials by a factor of three.

Case Study 3: Power Generation Facilities

In an electrical substation, engineers needed compliant hazard signage and circuit identification that would resist high voltage discharge and humidity. Standard inkjet labels failed within months.

By deploying custom thermal transfer labels made from durable vinyl and printed on Brother TD4 printers, the team achieved five-year label longevity. The project improved maintenance safety and met ANSI visibility standards.

Case Study 4: Marine Logistics

A shipping firm labeling metal cargo containers experienced fading and salt corrosion. After testing multiple materials, they switched to DuraFast’s weather-resistant vinyl and blue resin ribbons. The solution offered consistent adhesion on metal and passed 12-month salt-spray testing without degradation.

These real-world outcomes illustrate one truth: when paired with the right printer and ribbon, vinyl labels outperform nearly every other labeling substrate under demanding industrial conditions.

Integrating Vinyl Labeling into Lean Operations

Industrial businesses embracing lean manufacturing principles use labeling as part of visual management systems. Vinyl’s durability ensures that markings for safety, workflow zones, and equipment identification stay clear even in high-traffic or production-intensive areas.

1. Visual Efficiency

Permanent, color-coded vinyl labels streamline workflow by identifying materials, hazards, and pathways. Consistent visuals reduce employee confusion and improve response time.

2. Digital Integration

Modern vinyl label printers in Canada now integrate with enterprise software, automating print queues and reducing human error. This allows companies to print unique, traceable labels directly from production databases.

3. Cost Predictability

By standardizing materials and printers, facilities reduce variability in labeling expenses and avoid unscheduled downtime for reprints — a hallmark of efficient lean operations.

Training and Implementation Best Practices

Rolling out an industrial labeling program involves more than choosing materials — it’s about equipping your team with proper knowledge. DuraFast helps clients develop standardized label design templates, color codes, and printing protocols.

Training Recommendations:

- Conduct short workshops on printer maintenance and calibration.

- Create application checklists for operators (surface cleaning, pressure, curing).

- Use a label management software platform to enforce consistency across departments.

- Periodically review environmental wear and replace labels preemptively.

A well-trained workforce ensures the labeling system functions as part of a larger operational quality framework.

Durability That Works as Hard as You Do

Industrial labeling isn’t about aesthetics — it’s about safety, reliability, and compliance. Vinyl labels are the unsung heroes of modern manufacturing and field operations, quietly withstanding heat, chemicals, abrasion, and weather long after other materials fail.

With proper selection, printing, and care, these labels maintain performance for years, protecting your assets and reputation alike. Whether you’re marking electrical equipment, chemical containers, or outdoor machinery, vinyl ensures clarity and longevity where it matters most.

At DuraFast Label Company, we provide the tools, materials, and expertise to help you get it right the first time. From heavy-duty printers and custom thermal transfer labels to weather-tested adhesives and resin ribbons, every product is engineered for industrial dependability.

Explore our full range of vinyl labels in Canada — available in multiple colors, finishes, and adhesive types — and discover why professionals trust DuraFast for performance labeling solutions.

Ready to upgrade your labeling system for industrial durability? Contact DuraFast Label Company today and get expert guidance on choosing the right printer, ribbon, and vinyl label combination for your business.